| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000001H97O |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 09/2022] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING SYSTEM (for HV Model): P1C7C49; Hybrid/EV Battery Voltage System Isolation (A/C Area) Internal Electronic Failure; 2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022] | ||

|

DTC |

P1C7C49 |

Hybrid/EV Battery Voltage System Isolation (A/C Area) Internal Electronic Failure |

DESCRIPTION

This DTC is stored if there is insulation malfunction in the high-voltage circuit in the air conditioning system. Possible causes are poor insulation in the compressor with motor assembly, or mixing of any oil other than ND-OIL 11 in the refrigerant cycle.

A high-voltage motor is built into the compressor with motor assembly and is cooled directly with refrigerant. Compressor oil (ND-OIL 11) with high insulation performance is used because leakage of electrical power may occur if regular compressor oil (ND-OIL 8) is used.

CAUTION:

- Before inspecting the high-voltage system, take safety precautions such as wearing insulated gloves and removing the service plug grip to prevent electrical shocks. After removing the service plug grip, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

- Do not touch the high-voltage connectors or terminals for 10 minutes after the service plug grip is removed.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Memory |

|---|---|---|---|---|

|

P1C7C49 |

Hybrid/EV Battery Voltage System Isolation (A/C Area) Internal Electronic Failure |

High voltage system insulation malfunction |

|

Memorized |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

- Before inspecting the high-voltage system, take safety precautions such as wearing insulated gloves and removing the service plug grip to prevent electrical shocks. After removing the service plug grip, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

- Do not touch the high-voltage connectors or terminals for 10 minutes after the service plug grip is removed.

NOTICE:

- After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

- Electrical insulation performance may decrease significantly if even a small amount of oil other than ND-OIL 11 is used (or enters) in the refrigerant cycle, causing a DTC to be output.

- If oil other than ND-OIL 11 is accidentally used and a DTC is output, collect as much of the oil in the refrigerant cycle into the compressor with motor assembly as possible and replace it with ND-OIL 11 to increase the ND-OIL 11 ratio.

- Replace the main components of the refrigerant cycle (evaporator, condenser, and compressor) if a large amount of oil other than ND-OIL 11 enters the system. Failing to do so may cause electrical insulation performance to remain low, causing a DTC to be stored.

- The hybrid control system and air conditioning system output DTCs separately. Perform troubleshooting for the hybrid control system first if DTCs for both systems are output simultaneously.

- The air conditioning system uses the CAN communication system. Inspect the communication functions by following How to Proceed with Troubleshooting. Troubleshoot the air conditioning system after confirming that the communication systems are functioning properly.

HINT:

If it can be confirmed that any compressor oil other than ND-OIL 11 has been used, replace the main components of the refrigerant cycle.

PROCEDURE

|

1. |

INSPECT COMPRESSOR WITH MOTOR ASSEMBLY |

CAUTION:

Because the compressor with motor assembly has a high-voltage circuit, put on insulated gloves and remove the service plug grip to cut off the high-voltage circuit before inspecting the compressor with motor assembly.

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (READY).

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

(e) Clear the DTCs.

Powertrain > Hybrid Control > Clear DTCs

(f) Prepare the vehicle according to the table below for 3 minutes.

|

Item |

Condition |

|---|---|

|

Blower speed |

HI |

|

Temperature setting |

MAX COLD |

|

A/C switch |

On |

(g) Turn the power switch off.

(h) Remove the service plug grip.

CAUTION:

Do not touch the high-voltage connectors or terminals for 10 minutes after the service plug grip is removed.

NOTICE:

After removing the service plug grip, turning the power switch on (READY) may cause a malfunction. Do not turn the power switch on (READY) with the service plug grip removed.

|

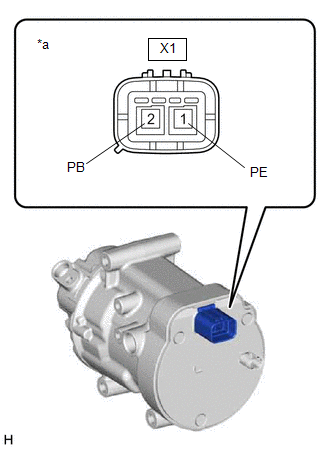

(i) Disconnect the compressor with motor assembly connector. |

|

(j) Using a megohmmeter, measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

X1-1 (PE) - Body ground |

Always |

2 MΩ or higher |

|

X1-2 (PB) - Body ground |

Always |

2 MΩ or higher |

| NG |

|

|

|

2. |

INSPECT REFRIGERANT CYCLE |

CAUTION:

Because the compressor with motor assembly has a high-voltage circuit, put on insulated gloves and remove the service plug grip to cut off the high-voltage circuit before inspecting the compressor with motor assembly.

(a) Connect the compressor with motor assembly connector.

(b) Install the service plug grip.

(c) Turn the power switch on (READY).

(d) Set the A/C temperature to 25°C (77°F) and blower switch to LO and operate the compressor with motor assembly for 10 minutes to circulate the refrigerant and collect as much compressor oil as possible in the compressor with motor assembly.

(e) Turn the power switch off.

(f) Using a spot cooler or other tool, cool down the compressor with motor assembly for 30 minutes, or leave the vehicle overnight before inspection.

NOTICE:

Do not operate the compressor before inspection.

(g) Remove the service plug grip.

CAUTION:

Do not touch the high-voltage connectors or terminals for 10 minutes after the service plug grip is removed.

NOTICE:

After removing the service plug grip, turning the power switch on (READY) may cause a malfunction. Do not turn the power switch on (READY) with the service plug grip removed.

|

(h) Disconnect the compressor with motor assembly connector. |

|

(i) Using a megohmmeter, measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

X1-1 (PE) - Body ground |

Always |

3 MΩ or higher |

|

X1-2 (PB) - Body ground |

Always |

3 MΩ or higher |

NOTICE:

If the result is not as specified, replace the compressor without operating it.

| OK |

|

| NG |

|

REPLACE MAIN COMPONENTS OF REFRIGERANT CYCLE |

|

|

|

![2019 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2018 - ]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)