- DTC judgment completed

- System normal

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000001GYSH |

| Model Year Start: 2020 | Model: Corolla Hatchback | Prod Date Range: [01/2019 - 11/2022] |

| Title: K313 (CVT): CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: P0705; Transmission Range Sensor Circuit (PRNDL Input); 2020 - 2023 MY Corolla Corolla Hatchback [01/2019 - 11/2022] | ||

|

DTC |

P0705 |

Transmission Range Sensor Circuit (PRNDL Input) |

DESCRIPTION

The park/neutral position switch assembly detects the shift lever position and send signals to the ECM.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

|---|---|---|---|---|---|

|

P0705 |

Transmission Range Sensor Circuit (PRNDL Input) |

Any of the following conditions are met (2-trip detection logic):

|

|

Comes on |

DTC stored |

DTC Detection Condition Patterns (P0705*):

|

Vehicle Condition |

|||||||

|---|---|---|---|---|---|---|---|

|

Pattern 1 |

Pattern 2 |

Pattern 3 |

Pattern 4 |

Pattern 5 |

Pattern 6 |

||

|

Diagnostic Condition |

Ignition switch is ON |

○ |

○ |

○ |

○ |

○ |

○ |

|

Battery voltage is 8 V or more |

○ |

○ |

○ |

○ |

○ |

○ |

|

|

Malfunction Condition |

NSW input signal is ON |

○ |

○ |

○ |

- |

- |

- |

|

P input signal is ON |

- |

- |

- |

○ |

○ |

○ |

|

|

R input signal is ON |

○ |

- |

- |

○ |

- |

- |

|

|

N input signal is ON |

- |

- |

- |

- |

- |

- |

|

|

D input signal is ON |

- |

○ |

- |

- |

○ |

- |

|

|

B input signal is ON |

- |

- |

○ |

- |

- |

○ |

|

|

Duration |

2 seconds or more |

2 seconds or more |

2 seconds or more |

2 seconds or more |

2 seconds or more |

2 seconds or more |

|

|

Detection Logic |

2-trip detection logic |

2-trip detection logic |

2-trip detection logic |

2-trip detection logic |

2-trip detection logic |

2-trip detection logic |

|

DTC Detection Condition Patterns (P0705*):

|

Vehicle Condition |

|||||||

|---|---|---|---|---|---|---|---|

|

Pattern 7 |

Pattern 8 |

Pattern 9 |

Pattern 10 |

Pattern 11 |

Pattern 12 |

||

|

Diagnostic Condition |

Ignition switch is ON |

○ |

○ |

○ |

○ |

○ |

○ |

|

Battery voltage is 8 V or more |

○ |

○ |

○ |

○ |

○ |

○ |

|

|

Malfunction Condition |

NSW input signal is ON |

- |

- |

- |

- |

- |

- |

|

P input signal is ON |

- |

- |

- |

- |

- |

- |

|

|

R input signal is ON |

○ |

- |

- |

○ |

○ |

- |

|

|

N input signal is ON |

○ |

○ |

○ |

- |

- |

- |

|

|

D input signal is ON |

- |

○ |

- |

○ |

- |

○ |

|

|

B input signal is ON |

- |

- |

○ |

- |

○ |

○ |

|

|

Duration |

2 seconds or more |

2 seconds or more |

2 seconds or more |

2 seconds or more |

2 seconds or more |

2 seconds or more |

|

|

Detection Logic |

2-trip detection logic |

2-trip detection logic |

2-trip detection logic |

2-trip detection logic |

2-trip detection logic |

2-trip detection logic |

|

HINT:

DTC P0705 is stored when any of the above detection patterns is met.

MONITOR DESCRIPTION

This DTC indicates a problem with the park/neutral position switch assembly or wire harness of their circuits.

The park/neutral position switch assembly detects the shift lever position and sends a signal to the ECM. For safety, the park/neutral position switch assembly detects the shift lever position so that the engine can be started only when the shift lever is in P or N.

The park/neutral position switch assembly sends a signal to the ECM according to the shift lever position (P, R, N, D or B).

The ECM determines that there is a problem with the switch or related parts if it receives more than 1 position signal simultaneously. The ECM will then illuminate the MIL and store a DTC.

MONITOR STRATEGY

|

Related DTCs |

P0705: Park/neutral position / Verify switch input |

|

Required sensors/Components |

Park/neutral position switch assembly |

|

Frequency of operation |

Continuous |

|

Duration |

Condition (A): 2 seconds Condition (B): 60 seconds |

|

MIL operation |

2 driving cycles |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

|

The monitor will run whenever the following DTCs are not present |

None |

|

Battery voltage |

10.5 V or more |

|

Time after battery voltage is 8 V or more |

0.5 seconds or more |

|

Write inhibit |

Permit |

|

Time after write status forbiddance to permit |

0.5 seconds or more |

|

Ignition switch |

ON |

|

Time after ignition switch OFF to ON |

0.5 seconds or more |

|

Starter |

OFF |

|

Time after starter ON to OFF |

0.5 seconds or more |

TYPICAL MALFUNCTION THRESHOLDS

Any of the following conditions are met: Condition (A) or (B)

Condition (A): When 2 or more of the following signals are input at the same time:

|

One of the following conditions is met: |

- |

|

- P position signal |

ON |

|

- N position signal |

ON |

|

- Park/neutral position signal |

ON |

|

R position signal |

ON |

|

D position signal |

ON |

|

B position signal |

ON |

Condition (B): All of the following signals are input at the same time:

|

P position signal |

OFF |

|

N position signal |

OFF |

|

Park/neutral position signal |

OFF |

|

R position signal |

OFF |

|

D position signal |

OFF |

|

B position signal |

OFF |

COMPONENT OPERATING RANGE

|

Park/neutral position switch signal |

Only one signal to the ECM. |

CONFIRMATION DRIVING PATTERN

HINT:

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON and turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

- Turn the ignition switch to ON and turn the Techstream on.

-

Wait with the shift lever in each position (P, R, N, D or B) for 60 seconds or more each with the ignition switch ON. [*1]

HINT:

[*1]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P0705.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

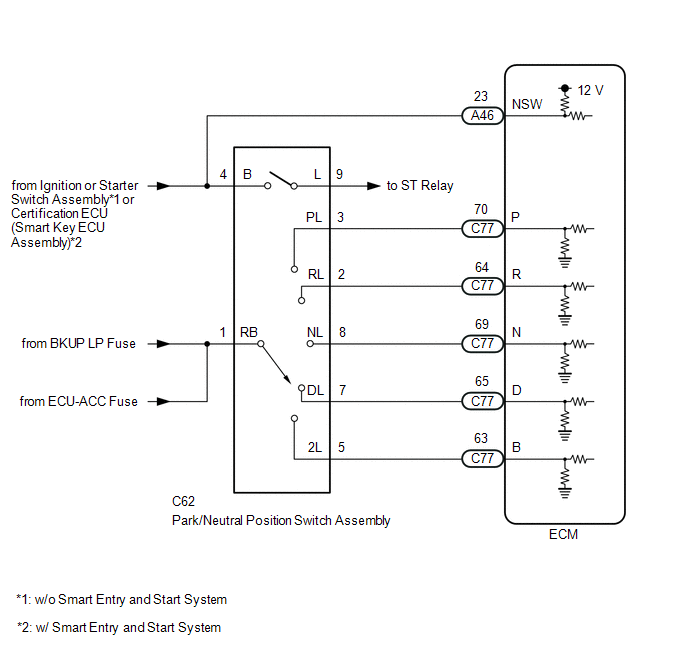

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Perform the universal trip to clear permanent DTCs.

- Perform initialization when parts related to the continuously variable transaxle system are replaced.

- Check that no DTCs are stored after performing initialization.

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (NEUTRAL POSITION SW SIGNAL AND SHIFT SW STATUS) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Data List.

(e) According to the display on the Techstream, read the Data List.

Powertrain > Engine and ECT > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Neutral Position SW Signal |

Park/neutral position switch status |

OFF or ON |

|

When the shift lever position displayed on the Techstream differs from the actual position, the adjustment of the park/neutral position switch assembly or shift cable may be incorrect. |

|

Shift SW Status (P Range) |

Park/neutral position switch status |

OFF or ON |

|

When the shift lever position displayed on the Techstream differs from the actual position, the adjustment of the park/neutral position switch assembly or shift cable may be incorrect. |

|

Shift SW Status (R Range) |

Park/neutral position switch status |

OFF or ON |

|

When the shift lever position displayed on the Techstream differs from the actual position, the adjustment of the park/neutral position switch assembly or shift cable may be incorrect. |

|

Shift SW Status (N Range) |

Park/neutral position switch status |

OFF or ON |

|

When the shift lever position displayed on the Techstream differs from the actual position, the adjustment of the park/neutral position switch assembly or shift cable may be incorrect. |

|

Shift SW Status (D Range) |

Park/neutral position switch status |

OFF or ON |

|

When the shift lever position displayed on the Techstream differs from the actual position, the adjustment of the park/neutral position switch assembly or shift cable may be incorrect. |

|

Shift SW Status (B Range) |

Park/neutral position switch status |

OFF or ON |

|

When the shift lever position displayed on the Techstream differs from the actual position, the adjustment of the park/neutral position switch assembly or shift cable may be incorrect. |

Powertrain > Engine and ECT > Data List

|

Tester Display |

|---|

|

Neutral Position SW Signal |

|

Shift SW Status (P Range) |

|

Shift SW Status (R Range) |

|

Shift SW Status (N Range) |

|

Shift SW Status (D Range) |

|

Shift SW Status (B Range) |

|

Result |

Proceed to |

|---|---|

|

Data List value is normal |

A |

|

Data List value is not normal |

B |

| A |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (BATTERY - PARK/NEUTRAL POSITION SWITCH ASSEMBLY) |

(a) Disconnect the C62 park/neutral position switch assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C62-1 (RB) - Body ground |

Ignition switch ON |

11 to 14 V |

|

C62-1 (RB) - Body ground |

Ignition switch off |

Below 1 V |

(c) Connect the C62 park/neutral position switch assembly connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (BATTERY - PARK/NEUTRAL POSITION SWITCH ASSEMBLY) |

|

|

3. |

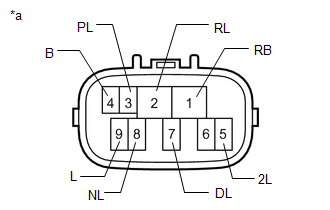

INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

|

(a) Disconnect the C62 park/neutral position switch assembly connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

4 (B) - 9 (L) |

Shift lever in P or N |

Below 1 Ω |

|

Shift lever not in P or N |

10 kΩ or higher |

|

|

1 (RB) - 3 (PL) |

Shift lever in P |

Below 1 Ω |

|

Shift lever not in P |

10 kΩ or higher |

|

|

1 (RB) - 2 (RL) |

Shift lever in R |

Below 1 Ω |

|

Shift lever not in R |

10 kΩ or higher |

|

|

1 (RB) - 8 (NL) |

Shift lever in N |

Below 1 Ω |

|

Shift lever not in N |

10 kΩ or higher |

|

|

1 (RB) - 7 (DL) |

Shift lever in D |

Below 1 Ω |

|

Shift lever not in D |

10 kΩ or higher |

|

|

1 (RB) - 5 (2L) |

Shift lever in B |

Below 1 Ω |

|

Shift lever not in B |

10 kΩ or higher |

(c) Connect the C62 park/neutral position switch assembly connector.

| NG |

|

|

|

4. |

CHECK HARNESS AND CONNECTOR (PARK/NEUTRAL POSITION SWITCH ASSEMBLY - ECM) |

(a) Disconnect the C62 park/neutral position switch assembly connector.

(b) Disconnect the A46 and C77 ECM connectors.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C62-3 (PL) - C77-70 (P) |

Always |

Below 1 Ω |

|

C62-2 (RL) - C77-64 (R) |

Always |

Below 1 Ω |

|

C62-8 (NL) - C77-69 (N) |

Always |

Below 1 Ω |

|

C62-7 (DL) - C77-65 (D) |

Always |

Below 1 Ω |

|

C62-5 (2L) - C77-63 (B) |

Always |

Below 1 Ω |

|

C62-4 (B) - A46-23 (NSW) |

Always |

Below 1 Ω |

|

C62-3 (PL) or C77-70 (P) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C62-2 (RL) or C77-64 (R) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C62-8 (NL) or C77-69 (N) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C62-7 (DL) or C77-65 (D) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C62-5 (2L) or C77-63 (B) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C62-4 (B) or A46-23 (NSW) - Body ground and other terminals |

Always |

10 kΩ or higher |

(d) Connect the A46 and C77 ECM connectors.

(e) Connect the C62 park/neutral position switch assembly connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (PARK/NEUTRAL POSITION SWITCH ASSEMBLY - ECM) |

|

|

5. |

REPLACE ECM |

(a) Replace the ECM.

| NEXT |

|

|

|

|

![2020 - 2023 MY Corolla Corolla Hatchback [01/2019 - 11/2022]; K313 (CVT): CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)