| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000001GW8A |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 09/2022] |

| Title: HEATING / AIR CONDITIONING: COMPRESSOR (for 2ZR-FXE): INSTALLATION; 2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022] | ||

INSTALLATION

PROCEDURE

1. ADJUST COMPRESSOR OIL

|

(a) When replacing the compressor with motor assembly with a new one, gradually discharge the inert gas from the service valve, and drain the following amount of oil from the new compressor with motor assembly before installation. Standard: (Oil capacity inside the new compressor with motor assembly: 110 to 125 cc (3.73 to 4.22 fl. oz)) - (Remaining oil amount in the removed compressor with motor assembly) - 65 cc (2.20 fl.oz) = (Oil amount to be removed from the new compressor) NOTICE:

|

|

2. INSTALL COMPRESSOR WITH MOTOR ASSEMBLY

|

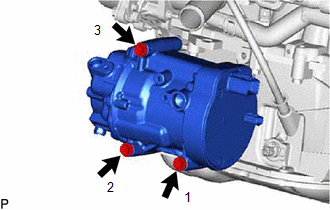

(a) Install the compressor with motor assembly with the 3 bolts. Torque: 25 N·m {255 kgf·cm, 18 ft·lbf} HINT: Tighten the bolts in the order shown in the illustration. |

|

(b) Install the bracket with the bolt.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

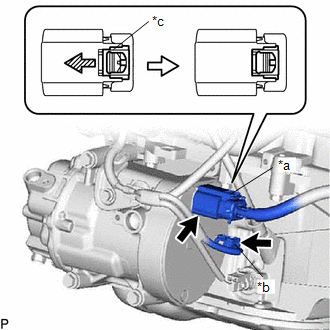

(c) Connect the connector (B).

|

*a |

Connector (A) |

|

*b |

Connector (B) |

|

*c |

Green-colored Lock |

|

Slide |

(d) Remove the insulating tape from the connector (A).

(e) Connect the connector (A) and slide the green-colored lock as shown in the illustration to securely lock it.

CAUTION:

Make sure to wear insulated gloves.

NOTICE:

Make sure that the connector is connected securely.

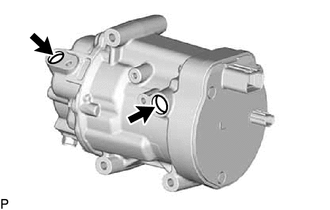

3. CONNECT SUCTION HOSE SUB-ASSEMBLY

(a) Remove the vinyl tape from the suction hose sub-assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the compressor with motor assembly.

Compressor Oil:

ND-OIL 11 or equivalent

(c) Install the O-ring to the suction hose sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(d) Connect the suction hose sub-assembly to the compressor with motor assembly with the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

4. CONNECT DISCHARGE HOSE SUB-ASSEMBLY

(a) Remove the vinyl tape from the discharge hose sub-assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the compressor with motor assembly.

Compressor Oil:

ND-OIL 11 or equivalent

(c) Install the O-ring to the discharge hose sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(d) Connect the discharge hose sub-assembly to the compressor with motor assembly with the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

5. INSTALL INLET NO. 1 AIR CLEANER

6. INSTALL AIR CLEANER BRACKET

7. INSTALL AIR CLEANER CASE SUB-ASSEMBLY

8. INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

9. INSTALL AIR CLEANER CAP SUB-ASSEMBLY

10. INSTALL AIR CLEANER HOSE ASSEMBLY

11. INSTALL INLET NO. 2 AIR CLEANER

12. INSTALL RADIATOR SUPPORT OPENING COVER

13. INSTALL SERVICE PLUG GRIP

14. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT (for HFC-134a(R134a))

15. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT (for HFO-1234yf(R1234yf))

16. WARM UP COMPRESSOR (for HFC-134a(R134a))

17. WARM UP COMPRESSOR (for HFO-1234yf(R1234yf))

18. INSPECT FOR REFRIGERANT LEAK (for HFC-134a(R134a))

19. INSPECT FOR REFRIGERANT LEAK (for HFO-1234yf(R1234yf))

|

|

|

![2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022]; 2ZR-FXE (INTAKE / EXHAUST): INTAKE MANIFOLD: INSTALLATION+](/t3Portal/stylegraphics/info.gif)