- Communication stop for "Skid Control (ABS/VSC/TRAC)" is indicated on the "Communication Bus Check" screen of the Techstream.

- Communication stop history for "Skid Control (ABS/VSC/TRAC)" is indicated on the "Communication Bus Check (Detail)" screen of the Techstream. (The Lost Communication Time value for "Skid Control (ABS/VSC/TRAC)" is 6 or more.)

- Communication system DTCs (DTCs that start with U) that correspond to "Skid Control ECU Communication Stop Mode" in "DTC Combination Table" are output.

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001GVYL |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 04/2020] |

| Title: NETWORKING: CAN COMMUNICATION SYSTEM (for HV Model): Skid Control ECU Communication Stop Mode; 2020 MY Corolla Corolla HV [01/2019 - 04/2020] | ||

|

Skid Control ECU Communication Stop Mode |

DESCRIPTION

|

Detection Item |

Symptom |

Trouble Area |

|---|---|---|

|

Skid Control ECU Communication Stop Mode |

Any of the following conditions are met: |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

NOTICE:

- Because the order of diagnosis is important to allow correct diagnosis, make sure to begin troubleshooting using How to Proceed with Troubleshooting when CAN communication system related DTCs are output.

- Before measuring the resistance of the CAN bus, turn the power switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) auxiliary battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

- After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

-

After performing repairs, perform the DTC check procedure and confirm that the DTCs are not output again.

DTC check procedure: Turn the power switch on (IG) and wait for 1 minute or more. Then operate the suspected malfunctioning system and drive the vehicle at 60 km/h (37 mph) or more for 5 minutes or more.

- After the repair, perform the CAN bus check and check that all the ECUs and sensors connected to the CAN communication system are displayed as normal.

- Inspect the fuses for circuits related to this system before performing the following procedure.

HINT:

- Before disconnecting related connectors for inspection, push in on each connector body to check that the connector is not loose or disconnected.

- When a connector is disconnected, check that the terminals and connector body are not cracked, deformed or corroded.

PROCEDURE

|

1. |

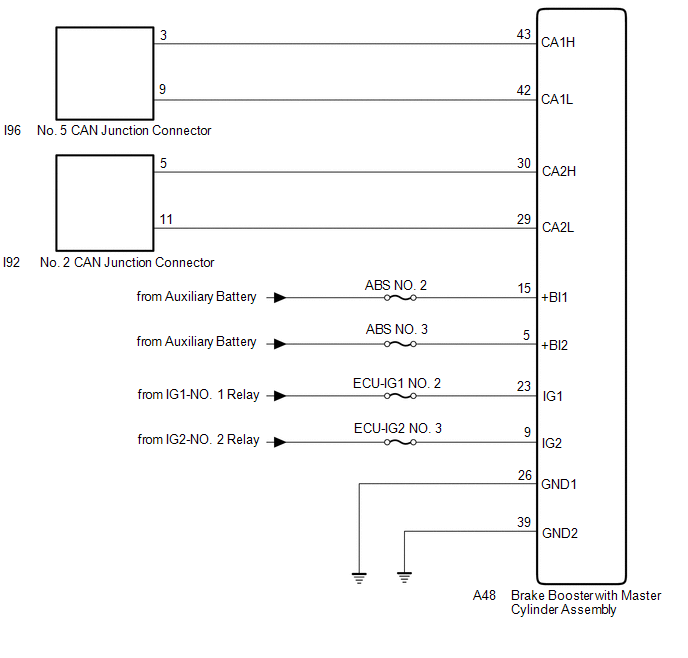

CHECK FOR OPEN IN CAN BUS LINES (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY BRANCH LINE) |

(a) Disconnect the cable from the negative (-) auxiliary battery terminal.

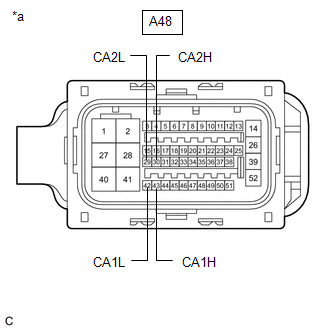

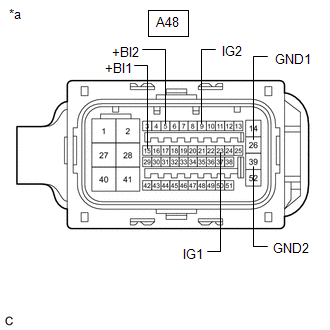

(b) Disconnect the A48 brake booster with master cylinder assembly connector.

|

(c) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

| NG |

|

REPAIR OR REPLACE CAN BRANCH LINES OR CONNECTOR (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY) |

|

|

2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

|

(a) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(b) Reconnect the cable to the negative (-) auxiliary battery terminal.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A48-5 (+BI2) - Body ground |

Power switch off |

11 to 14 V |

|

A48-15 (+BI1) - Body ground |

Power switch off |

11 to 14 V |

|

A48-9 (IG2) - Body ground |

Power switch on (IG) |

11 to 14 V |

|

A48-23 (IG1) - Body ground |

Power switch on (IG) |

11 to 14 V |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

|

|

|

![2020 MY Corolla Corolla HV [01/2019 - 04/2020]; NETWORKING: CAN COMMUNICATION SYSTEM (for HV Model): PROBLEM SYMPTOMS TABLE](/t3Portal/stylegraphics/info.gif)