| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000001GVVZ |

| Model Year Start: 2020 | Model: Corolla Hatchback | Prod Date Range: [01/2019 - 11/2022] |

| Title: K313 (CVT): TORQUE CONVERTER AND DRIVE PLATE: INSPECTION; 2020 - 2023 MY Corolla Corolla Hatchback [01/2019 - 11/2022] | ||

INSPECTION

PROCEDURE

1. INSPECT TORQUE CONVERTER ASSEMBLY

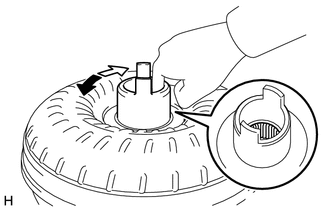

(a) Inspect the one-way clutch.

|

Difficult |

|

Smooth |

(1) Press on the spline of the stator with a finger and rotate the spline. Check that the spline rotates smoothly when turned clockwise and rotates with difficulty when turned counterclockwise.

If necessary, clean the torque converter assembly and recheck the one-way clutch.

Replace the torque converter assembly if the one-way clutch still fails the inspection.

|

(b) Inspect the torque converter assembly. If any of the following problems are present, replace the torque converter assembly. Malfunction:

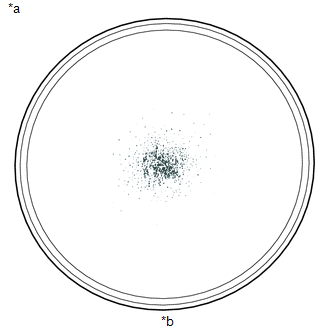

HINT: The sample shows approximately 0.025 liters (0.026 US qts, 0.022 Imp. qts) of fluid in Petridish, which has been taken from the torque converter assembly. |

|

(c) Replace the fluid in the torque converter assembly.

HINT:

If the fluid is discolored or has a foul odor, stir the fluid in the torque converter assembly and drain it before replacing the fluid.

|

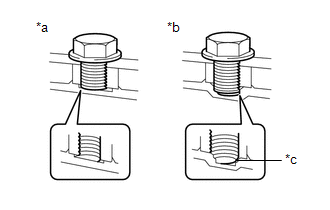

(d) Prevent deformation of the torque converter assembly and damage to the oil pump gear. NOTICE: Make sure that all of the bolts are the same length and that the specified bolts are used. HINT: If there is any damage to the tip of a bolt for the torque converter assembly or to the bottom of a bolt hole, replace the bolt and torque converter assembly. |

|

2. INSPECT DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

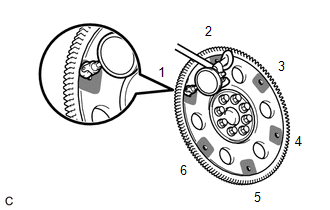

(a) Check the drive plate and ring gear sub-assembly for damage.

(b) Set up a dial indicator and measure the runout at the 6 areas on the drive plate and ring gear sub-assembly surface that contact the torque converter assembly.

|

Measurement Point |

Maximum Runout:

0.30 mm (0.0118 in.)

If the runout is more than the maximum or the drive plate and ring gear sub-assembly is damaged, replace the drive plate and ring gear sub-assembly.

If installing a new drive plate and ring gear sub-assembly, confirm that the spacers are oriented properly before tightening the bolts.

|

|

|

![2020 - 2023 MY Corolla [01/2019 - 11/2022]; 2ZR-FAE (ENGINE MECHANICAL): REAR CRANKSHAFT OIL SEAL: INSTALLATION](/t3Portal/stylegraphics/info.gif)