| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001GOQM |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 09/2022] |

| Title: BRAKE SYSTEM (OTHER): BRAKE BOOSTER (for HV Model): INSTALLATION; 2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022] | ||

INSTALLATION

PROCEDURE

1. INSTALL BRAKE BOOSTER GASKET

(a) Install a new brake booster gasket to the brake booster with master cylinder assembly.

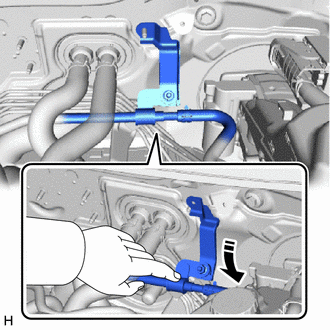

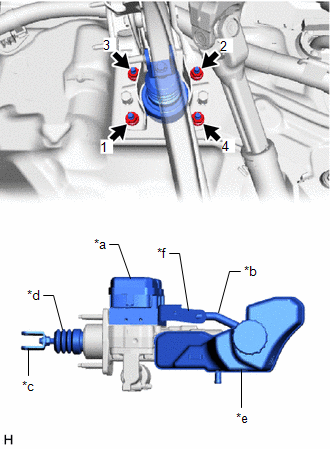

2. INSTALL BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY

|

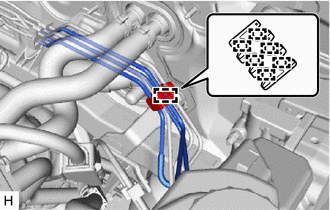

(a) Install the brake booster with master cylinder assembly with the 4 nuts. Torque: 12.7 N·m {130 kgf·cm, 9 ft·lbf} NOTICE:

|

|

3. INSTALL PUSH ROD PIN

4. INSTALL BRAKE PEDAL RETURN SPRING

5. CONNECT BRAKE LINE

|

(a) Engage the 6 clamps to install a new No. 2 brake tube clamp to the brake lines. NOTICE:

|

|

|

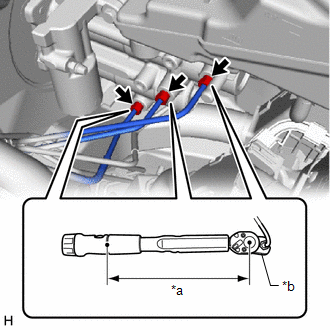

(b) Using a union nut wrench, connect the 3 brake lines to the brake booster with master cylinder assembly. Torque: Specified tightening torque : 15.2 N·m {155 kgf·cm, 11 ft·lbf} NOTICE:

|

|

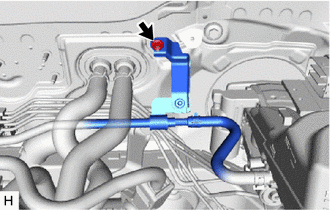

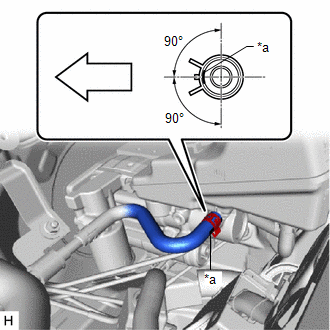

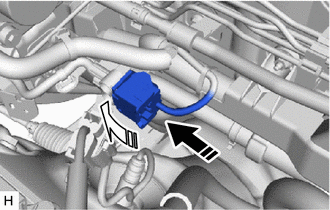

6. CONNECT NO. 2 BRAKE ACTUATOR HOSE

(a) Connect the No. 2 brake actuator hose to the brake booster with master cylinder assembly, and slide the clip to secure it.

|

*a |

Identification Mark |

|

Front of the vehicle |

NOTICE:

- Make sure to connect the No. 2 brake actuator hose with its identification mark facing the front of the vehicle.

- Install the clip within the range shown in the illustration.

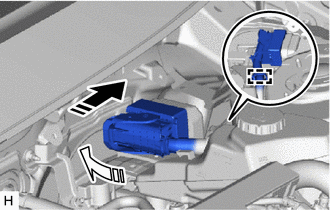

7. CONNECT ENGINE ROOM MAIN WIRE

(a) Connect the connector to the brake booster with master cylinder assembly and lock the lock lever as shown in the illustration.

|

Connect the connector |

|

Lock the lock lever |

NOTICE:

- Make sure that the connector is locked securely.

- Make sure that the connector can be connected smoothly. Do not allow water, oil or dirt to enter the connector.

(b) Engage the clamp to install the engine room main wire.

(c) Connect the connector to the brake booster with master cylinder assembly.

8. BLEED NO. 1 BRAKE ACTUATOR TUBE

NOTICE:

Make sure to bleed the air from the No. 1 brake actuator tube. If the air remains in the No. 1 brake actuator tube, the air will enter the brake booster pump assembly and may damage the brake booster pump assembly.

(a) Remove the brake master cylinder reservoir filler cap assembly.

(b) Add brake fluid to the reservoir until the fluid level is between the MAX and MIN lines on the brake fluid reservoir.

Brake Fluid:

SAE J1703 or FMVSS No. 116 DOT3

SAE J1704 or FMVSS No. 116 DOT4

|

(c) Remove the nut to separate the No. 1 brake actuator tube. HINT: If the No. 1 brake actuator tube has already been separated, it is not necessary to perform this step. |

|

|

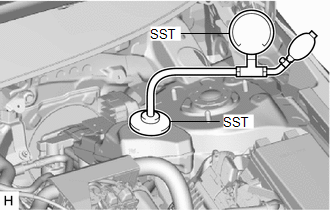

(d) Set SST to the brake master cylinder reservoir assembly. SST: 09992-00242 SST: 09992-00350 |

|

(e) Using SST, increase and then maintain the pressure in the brake master cylinder reservoir assembly for 60 seconds.(*1)

Standard Pressure:

50 to 80 kPa (0.6 to 0.8 kgf/cm2, 7.3 to 11.6 psi)

(f) Release the pressure in the brake master cylinder reservoir assembly and wait for 30 seconds.(*2)

(g) Repeat steps *1 to *2, 3 times.

(h) Remove SST.

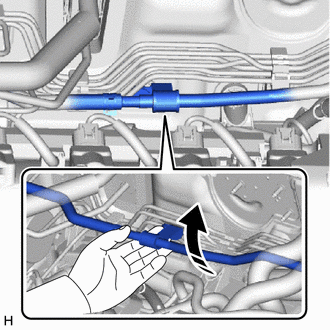

(i) Pull up the No. 1 brake actuator tube as shown in the illustration as high as possible for 10 seconds without damaging the bracket of the No. 1 brake actuator tube.(*3)

|

Pull up |

NOTICE:

Do not damage the hoses.

HINT:

Elevating the No. 2 brake actuator hose causes any air in the horizontal portion of the hose to flow to the brake master cylinder reservoir assembly side.

(j) Repeat step *3, 5 times.

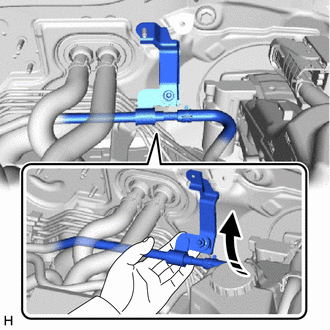

(k) Elevate the No. 1 brake actuator tube for 10 seconds by lifting the No. 1 brake actuator tube as shown in the illustration.(*4)

NOTICE:

Do not damage the hoses.

HINT:

Elevating the No. 1 brake actuator tube causes any air in the horizontal portion of the tube to flow to the brake master cylinder reservoir assembly side.

|

Pull up |

(l) Lower the No. 1 brake actuator tube for 10 seconds as shown in the illustration.(*5)

NOTICE:

Do not damage the hoses.

HINT:

Lowering the No. 1 brake actuator tube causes any air in the No. 1 brake actuator tube to flow to the brake master cylinder reservoir assembly side.

|

Press down |

(m) Repeat steps *4 to *5, 5 times.

(n) Install the No. 1 brake actuator tube with the nut.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

9. CONNECT BRAKE BOOSTER PUMP CONNECTOR

HINT:

Perform this operation only when the accumulator pressure zero down could not be performed using the Techstream.

(a) Connect the connector to the brake booster pump assembly and lock the lock lever as shown in the illustration.

|

Connect the connector |

|

Lock the lock lever |

NOTICE:

- Make sure that the connector is locked securely.

- Make sure that the connector can be connected smoothly. Do not allow water, oil or dirt to enter the connector.

10. FILL RESERVOIR WITH BRAKE FLUID

11. CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

12. BLEED BRAKE SYSTEM

13. INSPECT AND ADJUST BRAKE PEDAL

14. OBTAIN ZERO POINT OF YAW RATE AND ACCELERATION SENSOR

15. INSTALL NO. 1 INSTRUMENT PANEL UNDER COVER SUB-ASSEMBLY

16. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

17. INSTALL NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

18. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

|

|

|

![2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022]; BRAKE SYSTEM (OTHER): BRAKE PEDAL (for HV Model): INSTALLATION+](/t3Portal/stylegraphics/info.gif)