| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001GOOT |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 09/2022] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: BRAKE ACTUATOR (for HV Model): INSTALLATION; 2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022] | ||

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

The parking brake indicator light blinks (red) when the power switch is turned on after replacing the brake actuator assembly. Operate the electric parking brake switch assembly to turn off the parking brake indicator light.

PROCEDURE

1. INSTALL BRAKE ACTUATOR ASSEMBLY

(a) Install the brake actuator assembly to the brake actuator bracket assembly with the 3 bolts.

Torque:

6.5 N·m {66 kgf·cm, 58 in·lbf}

NOTICE:

- Do not remove the hole plugs of a new brake actuator assembly before connecting the brake lines because the brake actuator assembly is filled with brake fluid.

- Do not hold the brake actuator assembly by the connector.

- Do not apply excessive force to the brake lines.

- Be careful not to allow any brake fluid to enter the connector.

- Do not drop the brake actuator assembly when carrying it.

(b) Return the suction pipe sub-assembly and air conditioner tube and accessory assembly to its original position.

NOTICE:

Do not apply excessive force to the suction pipe sub-assembly and air conditioner tube and accessory assembly.

2. INSTALL BRAKE BOOSTER PUMP ASSEMBLY

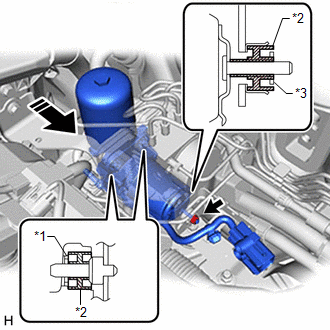

(a) Install the brake booster pump assembly to the brake actuator bracket assembly with the nut.

Torque:

6.5 N·m {66 kgf·cm, 58 in·lbf}

|

*1 |

Brake Booster Pump Collar |

|

*2 |

Brake Booster Pump Bushing |

|

*3 |

Brake Actuator Case Collar |

|

Install in this Direction |

NOTICE:

- Be careful not to allow any brake fluid to enter the connector.

- When installing the brake booster pump assembly to the brake actuator bracket assembly, confirm that the brake booster pump bushing and brake actuator case collar are on the brake actuator bracket assembly, and 2 brake booster pump bushings and 2 brake booster pump collars are on the brake booster pump assembly.

- Do not drop the brake booster pump assembly when carrying it.

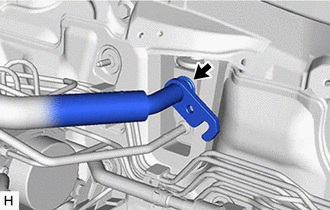

(b) Engage the claw and clamp to install the brake booster pump assembly wire harness to the brake actuator bracket assembly.

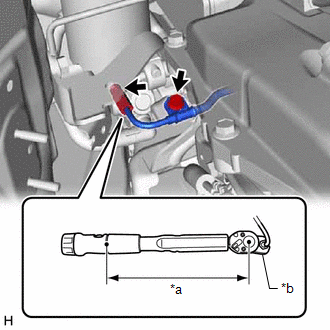

3. INSTALL ACCUMULATOR TO BRAKE MASTER CYLINDER TUBE

(a) Temporarily tighten the accumulator to brake master cylinder tube to the brake booster pump assembly.

|

(b) Install the accumulator to brake master cylinder tube with the bolt. Torque: 7.0 N·m {71 kgf·cm, 62 in·lbf} |

|

(c) Using a union nut wrench, tighten the accumulator to brake master cylinder tube.

Torque:

Specified tightening torque :

15.2 N·m {155 kgf·cm, 11 ft·lbf}

NOTICE:

- Do not kink or damage the accumulator to brake master cylinder tube.

- Do not allow the accumulator to brake master cylinder tube to twist or interfere with other parts or the vehicle body during tightening.

- Do not allow any foreign matter such as dirt or dust to enter the accumulator to brake master cylinder tube from the connecting parts.

HINT:

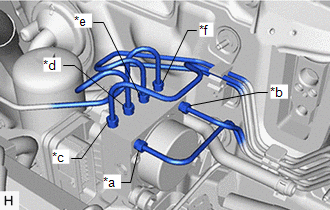

4. CONNECT BRAKE LINE

|

(a) Temporarily tighten the 6 brake lines to the correct positions on the brake actuator assembly as shown in the illustration. |

|

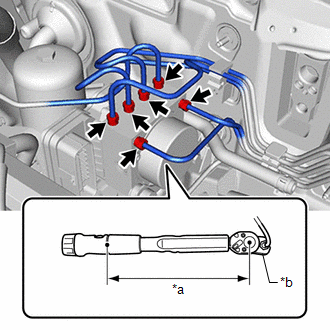

|

(b) Using a union nut wrench, fully tighten the 6 brake lines. Torque: Specified tightening torque : 15.2 N·m {155 kgf·cm, 11 ft·lbf} NOTICE:

|

|

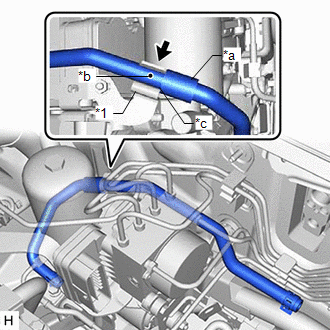

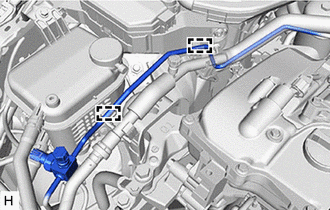

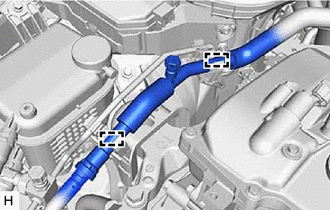

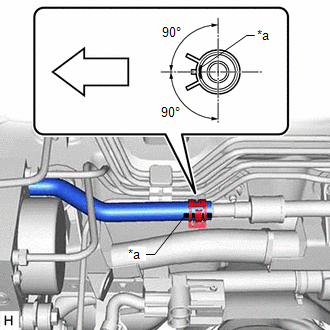

5. INSTALL NO. 1 BRAKE ACTUATOR HOSE

|

(a) Install the No. 1 brake actuator hose to the brake actuator hose clamp. NOTICE:

|

|

(b) Connect the No. 1 brake actuator hose to the No. 1 brake actuator tube to install it, and slide the clip to secure it.

|

*a |

Identification Mark |

|

Front of the vehicle |

NOTICE:

- Make sure to connect the No. 1 brake actuator hose with its identification mark facing the front of the vehicle.

- Install the clip within the range shown in the illustration.

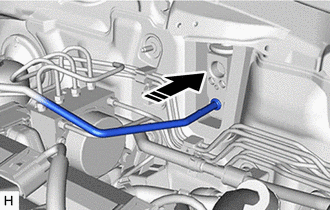

6. CONNECT ENGINE ROOM MAIN WIRE

(a) Connect the connector to the brake booster pump assembly and lock the lock lever as shown in the illustration.

|

Connect the connector |

|

Lock the lock lever |

NOTICE:

- Make sure that the connector is locked securely.

- Make sure that the connector can be connected smoothly. Do not allow water, oil or dirt to enter the connector.

(b) Connect the connector to the brake actuator assembly and lock the lock lever as shown in the illustration.

|

Connect the connector |

|

Lock the lock lever |

NOTICE:

- Make sure that the connector is locked securely.

- Make sure that the connector can be connected smoothly. Do not allow water, oil or dirt to enter the connector.

(c) Engage the clamp to install the engine room main wire.

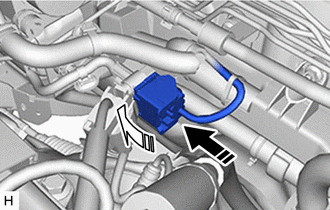

7. INSTALL AIR CONDITIONING TUBE & ACCESSORY ASSEMBLY

(a) Remove the vinyl tape from the air conditioner tube and accessory assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the air conditioner tube and accessory assembly.

Compressor Oil:

ND-OIL 11 or equivalent

(c) Install the O-ring to the air conditioner tube and accessory assembly.

NOTICE:

Keep the O-ring and O-ring fitting surfaces free of foreign matter.

(d) Connect the air conditioner tube and accessory assembly to the air conditioning unit assembly.

|

Install in this Direction |

|

(e) Engage the 2 clamps to install the air conditioner tube and accessory assembly. |

|

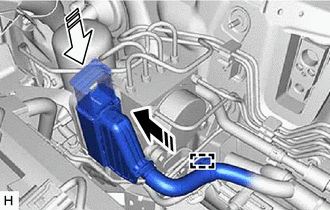

8. INSTALL SUCTION PIPE SUB-ASSEMBLY

(a) Remove the vinyl tape from the suction pipe sub-assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the suction pipe sub-assembly.

Compressor Oil:

ND-OIL 11 or equivalent

(c) Install the O-ring to the suction pipe sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surfaces free of foreign matter.

|

(d) Connect the suction pipe sub-assembly to the air conditioning unit assembly. |

|

|

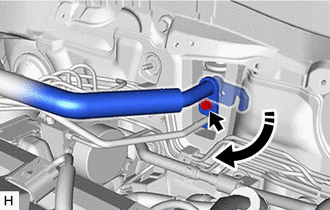

(e) Engage the 2 clamps to install the suction pipe sub-assembly. |

|

(f) Rotate the hook connector as shown in the illustration.

|

Rotate in this Direction |

(g) Insert the hose joint into the fitting hole securely and install the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

9. INSTALL SECURITY HORN ASSEMBLY

10. BLEED NO. 1 BRAKE ACTUATOR TUBE

11. FILL RESERVOIR WITH BRAKE FLUID

12. CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL

13. BLEED BRAKE SYSTEM

14. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

for HFC-134a(R134a): Click here

![2020 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [01/2019 - ]; HEATING / AIR CONDITIONING: REFRIGERANT (for HFC-134a(R134a)): REPLACEMENT+](/t3Portal/stylegraphics/info.gif)

for HFO-1234yf(R1234yf): Click here

![2020 - 2021 MY Corolla Corolla Hatchback Corolla HV GR Corolla [01/2019 - 06/2020]; HEATING / AIR CONDITIONING: REFRIGERANT (for HFO-1234yf(R1234yf)): REPLACEMENT+](/t3Portal/stylegraphics/info.gif)

![2021 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2020 - ]; HEATING / AIR CONDITIONING: REFRIGERANT (for HFO-1234yf(R1234yf)): REPLACEMENT+](/t3Portal/stylegraphics/info.gif)

15. WARM UP COMPRESSOR

for HFC-134a(R134a): Click here

![2020 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [01/2019 - ]; HEATING / AIR CONDITIONING: REFRIGERANT (for HFC-134a(R134a)): REPLACEMENT+](/t3Portal/stylegraphics/info.gif)

for HFO-1234yf(R1234yf): Click here

![2020 - 2021 MY Corolla Corolla Hatchback Corolla HV GR Corolla [01/2019 - 06/2020]; HEATING / AIR CONDITIONING: REFRIGERANT (for HFO-1234yf(R1234yf)): REPLACEMENT+](/t3Portal/stylegraphics/info.gif)

![2021 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2020 - ]; HEATING / AIR CONDITIONING: REFRIGERANT (for HFO-1234yf(R1234yf)): REPLACEMENT+](/t3Portal/stylegraphics/info.gif)

16. INSPECT FOR REFRIGERANT LEAK

for HFC-134a(R134a): Click here

![2020 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [01/2019 - ]; HEATING / AIR CONDITIONING: REFRIGERANT (for HFC-134a(R134a)): REPLACEMENT+](/t3Portal/stylegraphics/info.gif)

for HFO-1234yf(R1234yf): Click here

![2020 - 2021 MY Corolla Corolla Hatchback Corolla HV GR Corolla [01/2019 - 06/2020]; HEATING / AIR CONDITIONING: REFRIGERANT (for HFO-1234yf(R1234yf)): REPLACEMENT+](/t3Portal/stylegraphics/info.gif)

![2021 - 2025 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2020 - ]; HEATING / AIR CONDITIONING: REFRIGERANT (for HFO-1234yf(R1234yf)): REPLACEMENT+](/t3Portal/stylegraphics/info.gif)

17. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

18. INSTALL NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

19. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

|

|

|