| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001GMHJ |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - ] |

| Title: 2ZR-FXE (ENGINE MECHANICAL): CAMSHAFT: INSTALLATION; 2020 - 2025 MY Corolla Corolla HV [01/2019 - ] | ||

INSTALLATION

PROCEDURE

1. INSTALL NO. 1 CAMSHAFT BEARING

2. INSTALL NO. 2 CAMSHAFT BEARING

3. INSTALL CAMSHAFT TIMING GEAR ASSEMBLY

HINT:

Perform "Inspection After Repair" after replacing the camshaft timing gear assembly.

(a) Secure the hexagonal portion of the camshaft in a soft jaw vise.

|

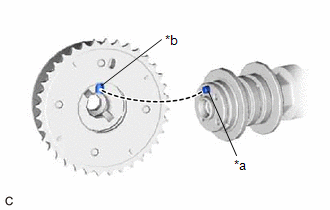

(b) Align and fit the knock pin of the camshaft to the knock pin hole of the camshaft timing gear assembly. |

|

|

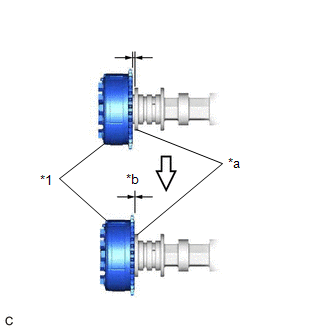

(c) Check that there is no gap between the camshaft timing gear assembly and camshaft flange. |

|

|

(d) Tighten the bolt with the camshaft timing gear assembly secured in place. Torque: 54 N·m {551 kgf·cm, 40 ft·lbf} NOTICE: When tightening the bolt, do not allow the camshaft timing gear assembly to rotate. |

|

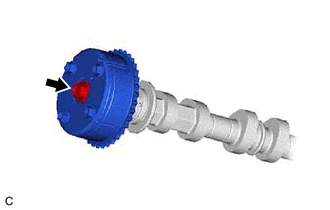

(e) Check that the camshaft timing gear assembly can move in the retard direction (clockwise) and locks in the most retarded position.

|

Lock |

4. SET NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

5. INSTALL CAMSHAFT

HINT:

Perform "Inspection After Repair" after replacing the camshaft.

(a) Clean the camshaft journals.

(b) Apply a light coat of engine oil to the camshaft journals, camshaft housing sub-assembly and camshaft bearing caps.

|

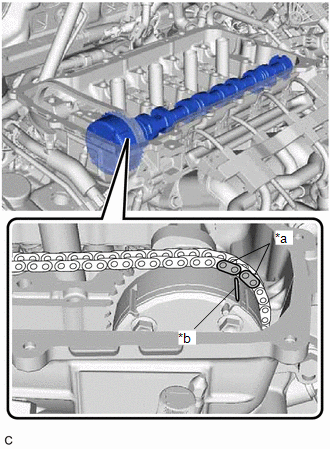

(c) Hold up the chain sub-assembly, align the timing mark with the paint mark and install the camshaft. |

|

6. INSTALL NO. 2 CAMSHAFT

HINT:

Perform "Inspection After Repair" after replacing the No. 2 camshaft.

(a) Clean the No. 2 camshaft journals.

(b) Apply a light coat of engine oil to the No. 2 camshaft journals, camshaft housing sub-assembly and camshaft bearing caps.

(c) Install the No. 2 camshaft to the camshaft housing sub-assembly.

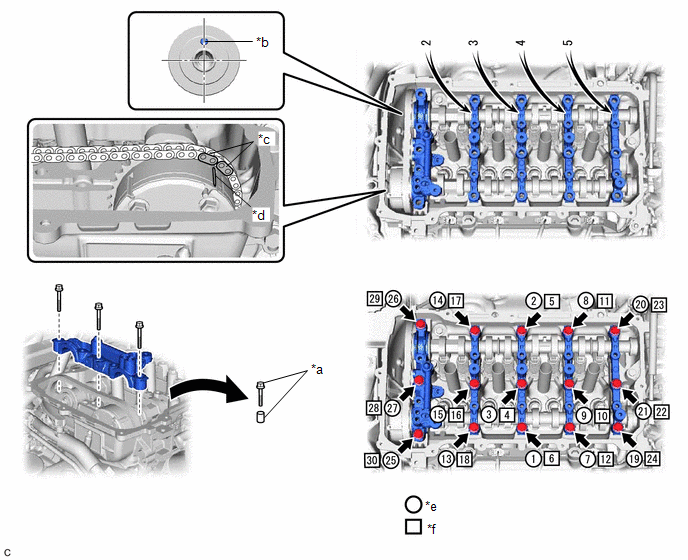

7. INSTALL CAMSHAFT BEARING CAP

(a) Check the marks and numbers on the camshaft bearing caps, and then remove the service bolts and spacers in the order shown in the illustration. Immediately after removing the service bolts and spacers for 1 camshaft bearing cap, install the camshaft bearing cap with the bolts in the order shown in the illustration.

|

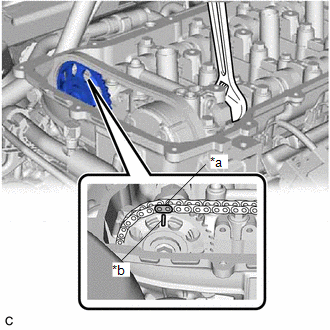

*a |

Service bolt and spacer (Used to temporarily secure the camshaft housing sub-assembly) |

*b |

Knock Pin |

|

*c |

Paint Mark |

*d |

Timing Mark |

|

*e |

The removal order of the service bolts and spacers for temporarily tightening the camshaft housing sub-assembly |

*f |

The installation order of the parts |

Torque:

27 N·m {275 kgf·cm, 20 ft·lbf}

NOTICE:

If the bolts are loosened all at once, seal packing on the camshaft housing sub-assembly and cylinder head sub-assembly may separate, resulting in oil leaks. Therefore, be sure to remove the service bolts and spacers from one camshaft bearing cap at a time.

HINT:

Make sure that the orientation of the straight pin, timing mark and paint mark of the camshaft are as shown in the illustration.

|

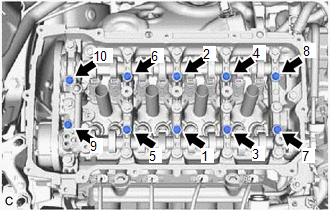

(b) Tighten the 10 bolts in the order shown in the illustration. Torque: 16 N·m {163 kgf·cm, 12 ft·lbf} |

|

(c) Check the torque of each bolt again.

8. INSTALL CAMSHAFT TIMING SPROCKET

|

(a) Hold the hexagonal portion of the camshaft with a wrench and turn the camshaft slightly counterclockwise to release the chain sub-assembly. NOTICE: Do not turn the camshaft more than necessary. |

|

(b) Align the paint mark with the timing mark to install the chain sub-assembly.

|

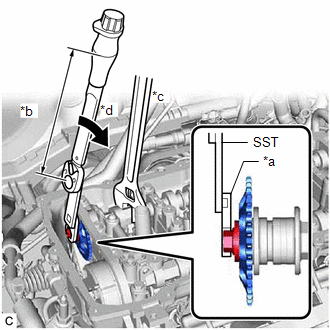

(c) Using SST, a 14 mm union nut wrench and a wrench, hold the hexagonal portion of the No. 2 camshaft and install the camshaft timing sprocket to the No. 2 camshaft. SST: 09961-00950 Torque: Specified tightening torque 54 N*m (551 kgf*cm, 40 ft.*lbf) HINT:

|

|

9. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

10. INSTALL NO. 2 CHAIN VIBRATION DAMPER

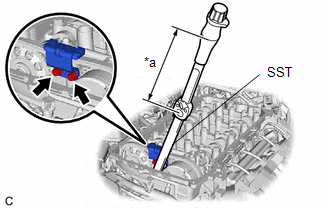

|

(a) Using SST, install the No. 2 chain vibration damper to the No. 1 camshaft bearing cap with the 2 bolts. SST: 09961-00950 Torque: Specified tightening torque 10 N*m (102 kgf*cm, 7 ft.*lbf) |

|

11. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

12. INSTALL SPARK PLUG TUBE GASKET

13. INSTALL CYLINDER HEAD COVER GASKET

14. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

15. INSTALL FUEL VAPOR FEED PIPE

16. INSTALL PURGE VALVE (PURGE VSV)

17. CONNECT NO. 9 WATER BY-PASS HOSE

18. CONNECT NO. 8 WATER BY-PASS HOSE

19. INSTALL EGR PIPE ASSEMBLY

20. CONNECT FUEL VAPOR FEED HOSE

21. CONNECT ENGINE WIRE

(a) Connect the engine wire to the cylinder head cover sub-assembly with the bolt.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(b) Engage the 4 clamps.

(c) Connect the 3 connectors.

22. INSTALL CAMSHAFT POSITION SENSOR

23. INSTALL IGNITION COIL ASSEMBLY

24. CONNECT NO. 2 VENTILATION HOSE

25. CONNECT FLOOR SHIFT TRANSMISSION CONTROL SELECT CABLE

(a) Connect the floor shift transmission control select cable to the cylinder head cover sub-assembly with the bolt.

Torque:

12 N·m {122 kgf·cm, 9 ft·lbf}

26. INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY

27. INSTALL NO. 1 HEATER AIR DUCT SPLASH SHIELD SEAL

28. INSTALL WINDSHIELD WIPER MOTOR AND LINK

29. ADD ENGINE COOLANT (for Engine)

30. INSPECT FOR COOLANT LEAK (for Engine)

31. INSTALL NO. 1 ENGINE UNDER COVER ASSEMBLY

|

|

|

![2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022]; 2ZR-FXE (ENGINE MECHANICAL): ENGINE UNIT: REASSEMBLY+](/t3Portal/stylegraphics/info.gif)