- Engine speed fluctuation due to abnormal combustion

- Idle speed too low or high

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001GKCG |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 11/2022] |

| Title: 2ZR-FAE (ENGINE CONTROL): SFI SYSTEM: Lack of Power; 2020 - 2023 MY Corolla [01/2019 - 11/2022] | ||

|

Lack of Power |

DESCRIPTION

|

Problem Symptom |

Suspected Area |

Trouble Area |

|

|---|---|---|---|

|

Strong engine vibration due to above symptoms |

|

Ignition system |

|

|

Fuel system |

|

||

|

Intake and exhaust systems |

|

||

|

Other control systems |

|

||

|

Engine |

|

||

|

High load from another system |

|

||

HINT:

- If any other DTCs are output, perform troubleshooting for those DTCs first.

- Make sure to reproduce the conditions present when the malfunction occurred.

- Using the Techstream, read the Data List to confirm the engine operating conditions. This information can be useful when troubleshooting.

- If the problem symptoms do not recur, attempt to reproduce the symptoms and conditions when the malfunction occurred based on the result of the customer problem analysis. Place the priority on confirming the symptoms.

SYMPTOM AND CAUSE OF SYSTEM MALFUNCTION

HINT:

The following are descriptions of the characteristics of each system malfunction. After understanding the link between the causes and symptoms, perform the inspection of each component. Even if the problem symptom does not recur, signs of the malfunction may be found in the Data List.

(a) Ignition system

Spark plug

|

Main cause of malfunction |

Performance degradation (wear, existence of foreign matter, etc.) |

|

Symptom |

Engine speed fluctuation due to abnormal combustion |

|

Data List |

Cylinder Misfire Count |

|

HINT: If the spark plug of the malfunctioning cylinder is abnormally wet with fuel, a leaking fuel injector assembly is suspected. |

|

Ignition coil assembly

|

Main cause of malfunction |

Internal malfunction |

|

Problem symptom |

Engine speed fluctuation due to abnormal combustion |

|

Data List |

Cylinder Misfire Count |

(b) Fuel system

Fuel injector assembly

|

Main cause of malfunction |

Blockage |

|

Problem symptom |

|

|

Data List |

|

|

HINT: If the engine malfunction disappears when the fuel injection volume is increased or decreased using the Control the Injection Volume, the respective cylinder may be malfunctioning. |

|

Fuel system

|

HINT: If the air fuel ratio becomes lean only when the engine is running under a high load and at a high engine speed, clogging of the fuel pump or fuel filter is suspected. |

Fuel quality

|

Main cause of malfunction |

|

|

Problem symptom |

|

(c) Intake and exhaust systems

Mass air flow meter sub-assembly

|

Main cause of malfunction |

Performance degradation (existence of foreign matter, etc.) |

|

Problem symptom |

Lack of power |

|

Data List |

MAF |

|

HINT: If the value of the Data List item "MAF" is abnormal, a malfunction of the mass air flow meter sub-assembly is suspected. |

|

Throttle system

|

Main cause of malfunction |

Inappropriate trim volume adjustment due to accumulation of deposits |

|

Problem symptom |

|

|

Data List |

|

Air fuel ratio sensor, Heated oxygen sensor

|

Main cause of malfunction |

Deviation in sensor characteristics |

|

Problem symptom |

Abnormal combustion due to deviation of actual air fuel ratio from calculated ratio |

|

Data List |

|

(d) Engine

Engine assembly

|

Main cause of malfunction |

|

|

Problem symptom |

|

|

HINT:

|

|

Data List Items Related to Lack of Power

HINT:

Depending on the vehicle model, the applicable Data List items may vary. Data List items other than the ones used in the diagnostic procedure are for reference only.

- MAF

- ISC Flow

- ISC Feedback Value

- ISC Learning Value

- Electric Load Feedback Val

- Air Conditioner FB Val

- Eng Stall Control FB Flow

- Target Air-Fuel Ratio

- AF Lambda B1S1

- AFS Voltage B1S1

- O2S B1S2

- Short FT B1S1

- Long FT B1S1

- Total FT #1

- Fuel System Status #1

- Cylinder #1 Misfire Count

- Cylinder #2 Misfire Count

- Cylinder #3 Misfire Count

- Cylinder #4 Misfire Count

- A/F Learn Value Idle #1

- A/F Learn Value Low #1

- A/F Learn Value Mid1 #1

- A/F Learn Value Mid2 #1

- A/F Learn Value High #1

PROCEDURE

|

1. |

INTERVIEW THE CUSTOMER |

(a) Interview the customer for details about the conditions when experiencing the lack of power.

HINT:

If a lack of power occurs when the engine is running under a high load and at a high engine speed, the fuel filter may be clogged.

|

|

2. |

CHECK DTC OUTPUT |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Perform a road test.

(e) Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

(f) Read the DTCs.

Powertrain > Engine and ECT > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs are not output |

A |

|

DTC is output (DTCs other than P1603, P1604 or P1605 are output) |

B |

| B |

|

|

|

3. |

SYMPTOM CONFIRMATION |

(a) Check if the problem symptoms reported in the customer problem analysis recur.

HINT:

If the problem symptoms do not recur, attempt to reproduce the conditions when the malfunction occurred based on the result of the customer problem analysis.

|

Result |

Proceed to |

|---|---|

|

The problem symptom recurs |

A |

|

The problem symptom does not recur (occurred in the past) |

B |

| B |

|

|

|

4. |

READ VALUE USING TECHSTREAM (ISC LEARNING VALUE) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Data List / ISC Learning Value.

Powertrain > Engine and ECT > Data List

|

Tester Display |

|---|

|

ISC Learning Value |

(e) Read the value displayed on the Techstream.

|

Result |

Proceed to |

|---|---|

|

Less than 6.2 L/s |

A |

|

Other than above |

B |

| B |

|

|

|

5. |

READ VALUE USING TECHSTREAM (KNOCK CORRECT LEARN VALUE) |

(a) Connect the Techstream to the DLC3.

(b) Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher.

(c) Turn the Techstream on.

(d) Idle the engine.

(e) Enter the following menus: Powertrain / Engine and ECT / Data List / Knock Correct Learn Value.

Powertrain > Engine and ECT > Data List

|

Tester Display |

|---|

|

Knock Correct Learn Value |

(f) Read the value.

|

Knock Correct Learn Value |

Proceed to |

|---|---|

|

5 deg(CA) or higher |

A |

|

Less than 5 deg(CA) |

B |

HINT:

- If the value shown in the Data List is below 5 deg(CA), interview the customer to check if the malfunction is caused by the quality of the fuel being used.

- If the result of the customer problem analysis is that improper fuel was not used or the type of fuel used is unknown, suggest that the customer refuel the vehicle with a different brand of fuel and then check if the malfunction symptoms disappear.

| B |

|

CONFIRM FUEL |

|

|

6. |

READ VALUE USING TECHSTREAM (SHORT FT B1S1 AND LONG FT B1S1) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Data List / Short FT B1S1 and Long FT B1S1.

Powertrain > Engine and ECT > Data List

|

Tester Display |

|---|

|

Short FT B1S1 |

|

Long FT B1S1 |

(e) Read the value displayed on the Techstream.

|

Data List |

Result |

Proceed to |

|---|---|---|

|

Short FT B1S1 + Long FT B1S1 |

-15% or higher, or less than 15% |

A |

|

Other than above |

B |

HINT:

- "Total FT #1" is used to detect an abnormal air fuel ratio. As the value of "Total FT #1" is corrected by the ECM before it is displayed in the Data List, the displayed value may not be equal to the sum of the measured "Short FT B1S1" and "Long FT B1S1".

- An abnormally lean or rich tendency can be checked by reading the following Data List items: A/F Learn Value Idle #1, A/F Learn Value Low #1, A/F Learn Value Mid1 #1, A/F Learn Value Mid2 #1 and A/F Learn Value High #1.

-

The following may cause a lean air fuel ratio (an operating range in which the air fuel ratio learned value correction is +15% or more):

- Decrease in fuel injector assembly injection volume

- Decrease in mass air flow meter sub-assembly output (due to existence of foreign matter)

- Air leaks in intake system after mass air flow meter sub-assembly

- Decrease in fuel pressure (at fuel filter, fuel pump or fuel pressure regulator assembly)

- On vehicles which the learning value for each operating range can be checked, if the value of "A/F Learn Value High #1" only is corrected to the positive side, a malfunction in the fuel system (clogging of the fuel pump or fuel filter) is suspected.

- On vehicles which the learning value for each operating range can be checked, if the value of "A/F Learn Value Idle #1" or "A/F Learn Value Low #1" only is corrected to the positive side, an air leak after the mass air flow meter sub-assembly is suspected.

-

The following may cause a rich air fuel ratio (an operating range in which the air fuel ratio learned value correction is -15% or less):

- Increase in the fuel injector assembly injection volume

- Purge VSV system

| B |

|

|

|

7. |

PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE SELECT CYLINDER FUEL CUT) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Start the engine.

HINT:

Reproduce the vehicle conditions when the malfunction occurred. (such as after the engine is warmed up or after a cold start).

(e) Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Select Cylinder Fuel Cut / Data List / Engine Speed.

Powertrain > Engine and ECT > Active Test

|

Active Test Display |

|---|

|

Control the Select Cylinder Fuel Cut |

|

Data List Display |

|---|

|

Engine Speed |

(f) According to the display on the Techstream, perform the Active Test and check for a malfunctioning cylinder.

HINT:

- Perform fuel-cut for each cylinder and check the change in the engine speed.

- If the engine speed of a cylinder does not change while performing the Active Test, it can be determined that the cylinder is malfunctioning.

- If the engine speed of all cylinders change while performing the Active Test, it can be determined that multiple cylinders are malfunctioning.

- A cylinder for which the Data List item "Cylinder Misfire Count" increases may be malfunctioning.

- If "Compression Leakage Count" in the Data List increases, misfiring due to insufficient compression may be occurring.

|

Result |

Proceed to |

|---|---|

|

One cylinder is malfunctioning |

A |

|

Multiple or all cylinders are malfunctioning, or the malfunctioning cylinder cannot be determined. |

B |

| B |

|

|

|

8. |

PERFORM ACTIVE TEST USING TECHSTREAM (CHECK THE CYLINDER COMPRESSION) |

HINT:

If the vehicle does not support the Active Test "Check the Cylinder Compression", measure the compression pressure. If the compression pressure is normal, go to step 9 (PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE INJECTION VOLUME)).

(a) Warm up the engine.

(b) Turn the ignition switch off.

(c) Connect the Techstream to the DLC3.

(d) Turn the ignition switch to ON.

(e) Turn the Techstream on.

(f) Enter the following menus: Powertrain / Engine and ECT / Active Test / Check the Cylinder Compression / Data List / Compression / Engine Speed of Cyl #1 to #4 and Av Engine Speed of All Cyl.

Powertrain > Engine and ECT > Active Test

|

Active Test Display |

|---|

|

Check the Cylinder Compression |

|

Data List Display |

|---|

|

Engine Speed of Cyl #1 |

|

Engine Speed of Cyl #2 |

|

Engine Speed of Cyl #3 |

|

Engine Speed of Cyl #4 |

|

Av Engine Speed of All Cyl |

HINT:

To display the entire Data List, press the pull down menu button next to Primary. Then select Compression.

(g) Push the snapshot button to turn the snapshot function on.

HINT:

Using the snapshot function, data can be recorded during the Active Test.

(h) While the engine is not running, press the Active Test button to change Check the Cylinder Compression to ON.

HINT:

After performing the above procedure, the Active Test will start. Fuel injection for all cylinders is prohibited and each cylinder engine speed measurement enters standby mode.

(i) Crank the engine for about 10 seconds.

HINT:

Continue to crank the engine until the values change from the default value (51199 rpm).

(j) Monitor the engine speed (Engine Speed of Cyl #1 to #4 and Av Engine Speed of All Cyl) displayed on the Techstream.

NOTICE:

- In order to protect the starter assembly, do not crank the engine continuously for 20 seconds or more.

- If it is necessary to crank the engine again after Check the Cylinder Compression has been changed to ON and the engine has been cranked once, press Exit to return to the Active Test menu screen. Then change Check the Cylinder Compression to ON and crank the engine.

- Make sure the battery is fully charged before performing this Active Test.

HINT:

- At first, the Techstream will display extremely high cylinder engine speed values. After approximately 10 seconds of engine cranking, the engine speed measurement of each cylinder will change to the actual engine speed.

- If the cylinder engine speed values (Engine Speed of Cyl #1 to #4) displayed in the Data List do not change from an extremely high value, return to the Active Test menu screen, change "Check the Cylinder Compression" to ON and crank the engine again within 1 second.

(k) Stop cranking the engine, and then change "Check the Cylinder Compression" to OFF after the engine stops.

NOTICE:

- If the Active Test is changed to OFF while the engine is being cranked, the engine will start.

- When performing the Active Test, DTC P1604 (Startability Malfunction) may be stored.

- After performing the Active Test, make sure to check and clear DTCs.

(l) Push the snapshot button to turn the snapshot function off.

(m) Select "Stored Data" on the Techstream screen, select the recorded data and display the data as a graph.

HINT:

If the data is not displayed as a graph, the change of the values cannot be observed.

(n) Read the value.

HINT:

- If the value of Data List item "Engine Speed of Cyl" of a cylinder is higher than other cylinders, the cylinder may be malfunctioning.

- If the value of Data List item "Engine Speed of Cyl" is high for only one cylinder, compression loss is suspected.

|

Result |

Proceed to |

|---|---|

|

There is no variation in "Engine Speed of Cyl" (All cylinders display approximately the same value for "Engine Speed of Cyl") |

A |

|

There is variation in "Engine Speed of Cyl" (Only one cylinder displays a value for "Engine Speed of Cyl" that differs considerably) |

B |

| B |

|

|

|

9. |

PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE INJECTION VOLUME) |

(a) Connect the Techstream to the DLC3.

(b) Start the engine and warm it up until the engine coolant temperature 75°C (167°F) or higher with all the accessories switched off.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Injection Volume / Data List / Coolant Temp.

Powertrain > Engine and ECT > Active Test

|

Active Test Display |

|---|

|

Control the Injection Volume |

|

Data List Display |

|---|

|

Coolant Temp |

(e) According to the display on the Techstream, perform the Active Test and check the vehicle conditions when increasing and decreasing the fuel injection volume.

HINT:

Change the fuel injection volume between the minimum and maximum range of correction (e.g. -12.5% to 12.5%).

|

Result |

Proceed to |

|---|---|

|

Malfunction is still present even if the fuel injection volume is changed |

A |

|

Malfunction disappears when the fuel injection volume is changed |

B |

| B |

|

|

|

10. |

CHECK IGNITION SYSTEM |

(a) Check the ignition system.

HINT:

- Interchange the ignition coil assembly and spark plug of the malfunctioning cylinder with those of a known good cylinder and check if the malfunctioning cylinder returns to normal.

- If the spark plug of the malfunctioning cylinder is abnormally wet with fuel even after the ignition coil assembly and spark plug are replaced, a leaking fuel injector assembly is suspected.

|

Result |

Proceed to |

|---|---|

|

The malfunctioning cylinder does not return to normal |

A |

|

The malfunctioning cylinder returned to normal |

B |

| B |

|

|

|

11. |

INSPECT OTHER RELATED COMPONENTS |

(a) Check the power source circuit, wire harness and connectors.

| NEXT |

|

|

12. |

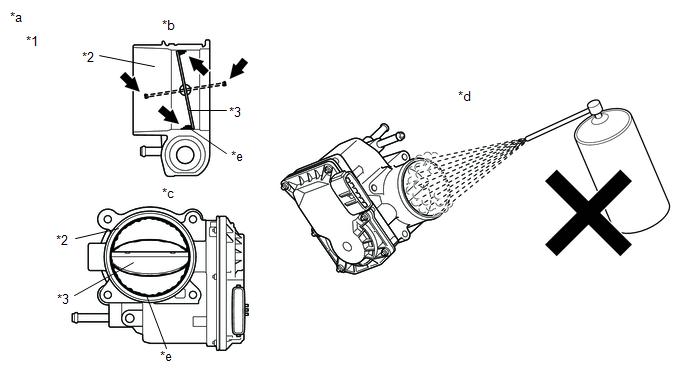

REMOVE FOREIGN OBJECT (CLEAN THROTTLE BODY ASSEMBLY) |

(a) Clean off any deposits from the inside of the throttle body assembly.

(b) Push open the throttle valve and wipe off any carbon from the valve and bore using a piece of cloth soaked in non-residue solvent.

|

*1 |

Throttle Body Assembly |

*2 |

Bore |

|

*3 |

Valve |

- |

- |

|

*a |

Reference |

*b |

Throttle Body Assembly Cross-section Diagram |

|

*c |

When valve fully opened |

*d |

Do not directly apply cleaner |

|

*e |

Deposits |

- |

- |

NOTICE:

- Make sure that the cloth or your fingers do not get caught in the valve.

- Make sure that foreign matter does not enter the throttle valve.

- Do not directly apply non-residue solvent to the throttle body assembly or wash the throttle body assembly. Cleaning solvent may leak into the motor from the shaft and cause problems such as rust or valve movement problems.

- If there is coating material on the edge of the valve, be careful not to remove it.

HINT:

The illustrations are for reference only. Actual parts may differ.

|

|

13. |

PERFORM CONFIRMATION DRIVING PATTERN |

(a) Perform "Inspection After Repair" after cleaning the throttle body assembly.

(b) Connect the Techstream to the DLC3.

(c) Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher.

(d) Turn the Techstream on.

(e) Allow the engine to idle for 3 minutes or more and confirm that the engine speed is within the specified range.

HINT:

If the engine is operated without performing learning value reset and idle learning after cleaning the deposits from the throttle body assembly, the idle speed may increase.

| NEXT |

|

|

14. |

CHECK CYLINDER COMPRESSION PRESSURE |

(a) Measure the cylinder compression pressure. If the compression pressure of a cylinder is low, inspect the engine assembly and repair or replace parts as necessary.

| NEXT |

|

|

15. |

REPLACE FUEL INJECTOR ASSEMBLY |

(a) Replace the fuel injector assembly of the malfunctioning cylinder.

HINT:

| NEXT |

|

|

16. |

READ VALUE USING TECHSTREAM (MAF) |

(a) Connect the Techstream to the DLC3.

(b) Start the engine and warm it up until the engine coolant temperature 75°C (167°F) or higher with all the accessories switched off.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Data List / Engine Speed, MAF and Coolant Temp.

Powertrain > Engine and ECT > Data List

|

Tester Display |

|---|

|

Engine Speed |

|

MAF |

|

Coolant Temp |

(e) According to the display on the Techstream, read the Data List when the engine is running.

|

Result |

Proceed to |

|---|---|

|

A |

|

Other than above |

B |

| B |

|

|

|

17. |

PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE INJECTION VOLUME FOR A/F SENSOR) |

(a) Connect the Techstream to the DLC3.

(b) Start the engine and warm it up until the engine coolant temperature 75°C (167°F) or higher with all the accessories switched off.

(c) Turn the Techstream on.

(d) Warm up the air fuel ratio sensor at an engine speed of 2500 rpm for 90 seconds.

(e) Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Injection Volume for A/F Sensor / Data List / Coolant Temp, AFS Voltage B1S1 and O2S B1S2.

Powertrain > Engine and ECT > Active Test

|

Active Test Display |

|---|

|

Control the Injection Volume for A/F Sensor |

|

Data List Display |

|---|

|

Coolant Temp |

|

AFS Voltage B1S1 |

|

O2S B1S2 |

(f) According to the display on the Techstream, perform the Active Test and check the vehicle conditions when increasing and decreasing the fuel injection volume.

NOTICE:

- The air fuel ratio sensor has an output delay of a few seconds and the heated oxygen sensor has a maximum output delay of approximately 20 seconds.

- Read the output voltage immediately after warming up the air fuel ratio sensor and heated oxygen sensor to avoid an inaccurate reading due to a sensor cooling.

HINT:

The Control the Injection Volume for A/F Sensor operation lowers the fuel injection volume by 12.5% or increases the injection volume by 12.5%.

|

Techstream Display (Sensor) |

Injection Volume |

Voltage |

|---|---|---|

|

AFS Voltage B1S1 (Air fuel ratio) |

12.5% |

Below 3.1 V |

|

-12.5% |

Higher than 3.4 V |

|

|

O2S B1S2 (Heated oxygen) |

12.5% |

Higher than 0.55 V |

|

-12.5% |

Below 0.4 V |

|

Result |

Proceed to |

|---|---|

|

Output voltage values are abnormal |

A |

|

Malfunction disappears when fuel injection volume is increased |

B |

|

Malfunction is still present when fuel injection volume is increased, even if output voltage values are normal |

C |

| B |

|

| C |

|

|

|

18. |

REPLACE AIR FUEL RATIO SENSOR AND HEATED OXYGEN SENSOR |

(a) Replace the air fuel ratio sensor.

HINT:

Perform "Inspection After Repair" after replacing the air fuel ratio sensor.

(b) Replace the heated oxygen sensor.

HINT:

Perform "Inspection After Repair" after replacing the heated oxygen sensor.

| NEXT |

|

|

19. |

REPLACE FUEL INJECTOR ASSEMBLY |

(a) Replace the fuel injector assemblies of all cylinders.

HINT:

Perform "Inspection After Repair" after replacing the fuel injector assembly.

| NEXT |

|

|

20. |

CHECK INTAKE SYSTEM |

(a) Check for air leaks or blockage in the intake system components. If a connection problem or foreign matter is found, repair the connection or remove the foreign matter.

HINT:

- If there is foreign matter in the intake system components, remove it before proceeding to the next step.

- If there is no foreign matter in the intake system components, check for foreign matter in the mass air flow meter sub-assembly. If there is foreign matter in the mass air flow meter sub-assembly, remove it.

| NEXT |

|

|

21. |

PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE FUEL PUMP / SPEED) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

Powertrain > Engine and ECT > Active Test

|

Tester Display |

|---|

|

Control the Fuel Pump / Speed |

(e) When performing the Active Test, check for an operating sound from the fuel pump.

OK:

|

Control the Fuel Pump / Speed |

Specified Condition |

|---|---|

|

ON |

Operating sound heard |

|

OFF |

Operating sound not heard |

| NG |

|

|

|

22. |

INSPECT FUEL PUMP |

(a) Attach a fuel pressure gauge and check the fuel pressure when cranking the engine and after stopping the engine.

Standard:

|

Vehicle State |

Specified Condition |

|---|---|

|

Cranking engine |

304 to 343 kPa (3.1 to 3.5 kgf/cm2, 44 to 50 psi) |

|

5 minutes after stopping engine |

147 kPa (1.5 kgf/cm2, 21 psi) or higher |

HINT:

- If there is foreign matter such as iron particles on the fuel pump, remove it.

- Make sure that there are no leaks from the fuel lines, signs of fuel leakage or fuel odors.

| NG |

|

|

|

23. |

INSPECT OTHER RELATED COMPONENTS |

(a) Inspect other related components.

HINT:

If the malfunctioning part could not be determined by performing the preceding inspections, one of the following malfunctions is suspected.

- Deposits in the intake manifold or on an intake valve

- Delay in fuel supply due to adherence of the fuel to the deposits

| NEXT |

|

|

24. |

INSPECT RELATED PARTS |

(a) Inspect the following fuel pump related parts:

- Fuel pump

- Fuel pressure regulator assembly

- Fuel lines and connecting parts

- Fuel filter

| NEXT |

|

|

25. |

INSPECT FUEL PUMP CONTROL SYSTEM |

(a) Inspect the fuel pump control system.

|

|

26. |

REPAIR OR REPLACE MALFUNCTIONING PARTS |

(a) Repair or replace the malfunctioning part.

HINT:

Perform "Inspection After Repair" after repairing or replacing the malfunctioning part.

|

|

27. |

CONDUCT CONFIRMATION TEST |

(a) Check that the engine has returned to normal.

| NEXT |

|

END |

|

|

|

![2020 MY Corolla [01/2019 - 03/2019]; 2ZR-FAE (ENGINE CONTROL): SFI SYSTEM: DIAGNOSTIC TROUBLE CODE CHART](/t3Portal/stylegraphics/info.gif)