| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000001GKC7 |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 11/2022] |

| Title: 2ZR-FAE (ENGINE CONTROL): SFI SYSTEM: Fuel Pump Control Circuit; 2020 - 2023 MY Corolla [01/2019 - 11/2022] | ||

|

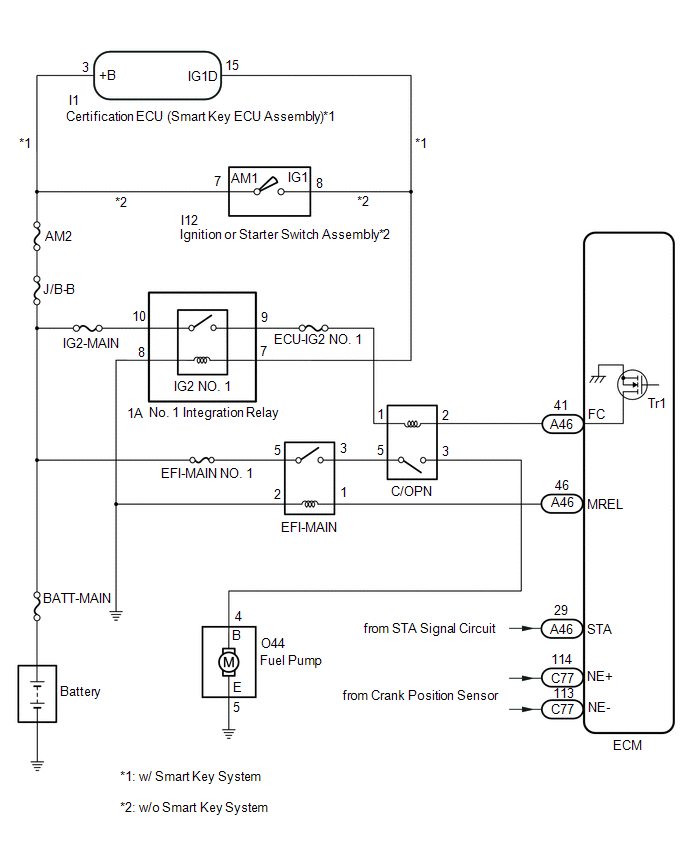

Fuel Pump Control Circuit |

DESCRIPTION

When the engine is cranked, the ST relay drive signal output from the ignition or starter switch assembly*1 or certification ECU (smart key ECU assembly)*2 is input into the STA terminal of the ECM, and the NE signal generated by the crank position sensor is also input into the NE+ terminal. The ECM interprets that the engine is cranked, and turns transistor Tr1 in the ECM internal circuit on. Current flows to the C/OPN relay by turning Tr1 on. Then, the fuel pump operates.

While the NE signal is input into the ECM with the engine running, the ECM turns Tr1 on continuously.

- *1: w/o Smart Key System

- *2: w/ Smart Key System

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Inspect the fuses for circuits related to this system before performing the following procedure.

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM (CONTROL THE FUEL PUMP/SPEED) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump/Speed.

Powertrain > Engine and ECT > Active Test

|

Tester Display |

|---|

|

Control the Fuel Pump / Speed |

(e) Check whether the fuel pump operating sound occurs when performing the Active Test on the Techstream.

|

Result |

Proceed to |

|---|---|

|

Fuel pump operating sound does not occur |

A |

|

Fuel pump operating sound occurs |

B |

| B |

|

|

|

2. |

CHECK TERMINAL VOLTAGE (POWER SOURCE OF C/OPN RELAY) |

|

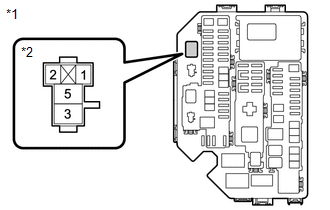

(a) Remove the C/OPN relay from the No. 1 engine room relay block and No. 1 junction block assembly. |

|

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (C/OPN relay) - Body ground |

Ignition switch ON |

11 to 14 V |

| NG |

|

|

|

3. |

INSPECT C/OPN RELAY |

(a) Inspect the C/OPN relay.

| NG |

|

REPLACE C/OPN RELAY |

|

|

4. |

CHECK HARNESS AND CONNECTOR (C/OPN RELAY - ECM) |

(a) Remove the C/OPN relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2 (C/OPN relay) - A46-41 (FC) |

Always |

Below 1 Ω |

|

2 (C/OPN relay) or A46-41 (FC) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

CHECK HARNESS AND CONNECTOR (C/OPN RELAY - FUEL PUMP) |

(a) Remove the C/OPN relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Disconnect the fuel pump connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 (C/OPN relay) - O44-4 (B) |

Always |

Below 1 Ω |

|

3 (C/OPN relay) or O44-4 (B) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CHECK HARNESS AND CONNECTOR (FUEL PUMP - BODY GROUND) |

(a) Disconnect the fuel pump connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

O44-5 (E) - Body ground |

Always |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

7. |

INSPECT FUEL PUMP |

(a) Inspect the fuel pump.

HINT:

Perform "Inspection After Repair" after replacing the fuel pump.

| NG |

|

|

|

8. |

CHECK HARNESS AND CONNECTOR (EFI-MAIN RELAY - C/OPN RELAY) |

(a) Remove the EFI-MAIN relay and C/OPN relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3 (EFI-MAIN relay) - 5 (C/OPN relay) |

Always |

Below 1 Ω |

|

3 (EFI-MAIN relay) or 5 (C/OPN relay) - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

9. |

CHECK HARNESS AND CONNECTOR (NO. 1 INTEGRATION RELAY - C/OPN RELAY) |

(a) Disconnect the No. 1 integration relay connector.

(b) Remove the C/OPN relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1A-9 - 1 (C/OPN relay) |

Always |

Below 1 Ω |

|

1A-9 or 1 (C/OPN relay) - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

10. |

READ VALUE USING TECHSTREAM (STARTER SIGNAL) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Data List / Starter Signal.

Powertrain > Engine and ECT > Data List

|

Tester Display |

|---|

|

Starter Signal |

(e) Check the result when the ignition switch is ON and the engine starts.

OK:

|

Condition |

Starter Signal |

|---|---|

|

Ignition switch ON |

OFF |

|

Engine started |

ON |

| NG |

|

|

|

11. |

READ VALUE USING TECHSTREAM (ENGINE SPEED) |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Data List / Engine Speed.

Powertrain > Engine and ECT > Data List

|

Tester Display |

|---|

|

Engine Speed |

(e) Read the values displayed on the Techstream while cranking.

OK:

Values are displayed continuously.

| OK |

|

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE

|

| NG |

|

|

|

|

![2020 - 2023 MY Corolla [01/2019 - 11/2022]; 2ZR-FAE (ENGINE CONTROL): RELAY: ON-VEHICLE INSPECTION+](/t3Portal/stylegraphics/info.gif)