| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001GKC6 |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 03/2019] |

| Title: 2ZR-FAE (ENGINE CONTROL): SFI SYSTEM: VC Output Circuit; 2020 MY Corolla [01/2019 - 03/2019] | ||

|

VC Output Circuit |

DESCRIPTION

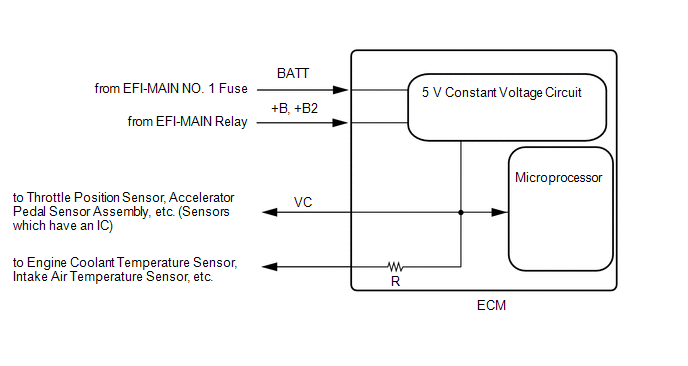

The ECM constantly generates a 5 V power source voltage from the battery voltage supplied to the +B, +B2 (BATT) terminals to operate the microprocessor. The ECM also provides this power to the sensors through the VC output circuit.

When the VC circuit has a short circuit, the microprocessor in the ECM and sensors that are supplied power through the VC circuit are deactivated because power is not supplied from the VC circuit. When the system is in this condition, it will not start.

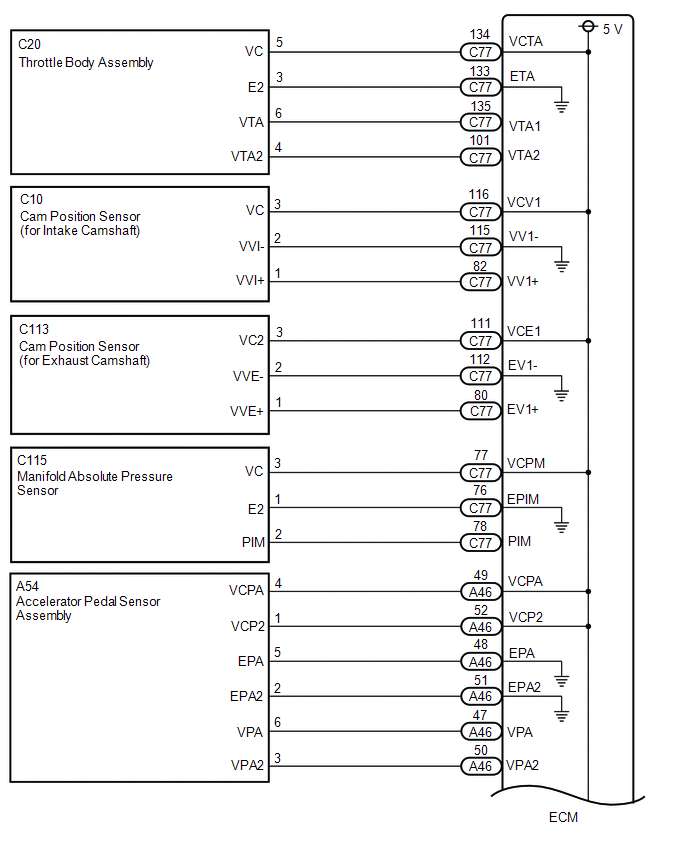

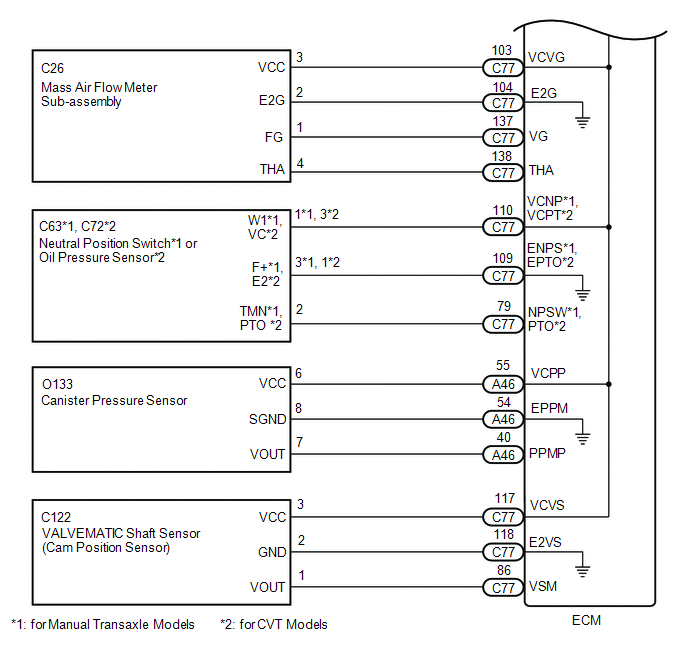

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

Check the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

|

1. |

CHECK CONNECTION BETWEEN TECHSTREAM AND ECM |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

| B |

|

PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

|

2. |

CHECK EFI NO. 2 FUSE VOLTAGE |

|

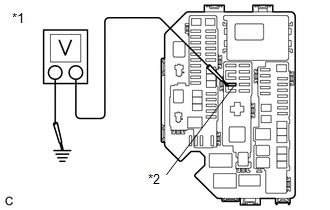

*1 |

No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly |

|

*2 |

EFI NO. 2 Fuse |

(a) Turn the ignition switch to ON.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

1 (EFI NO. 2 fuse) - Body ground |

Ignition switch ON |

11 to 14 V |

HINT:

- Check the fuse with it installed to the No. 1 engine room relay block and No. 1 junction block assembly.

- If the result is not as specified, since current is not flowing to the +B and +B2 terminals of the ECM, the system may not be started.

| NG |

|

|

|

3. |

CHECK CONNECTION BETWEEN TECHSTREAM AND ECM (THROTTLE POSITION SENSOR) |

(a) Disconnect the throttle body assembly connector.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

HINT:

Perform "Inspection After Repair" after replacing the throttle body assembly.

| B |

|

|

|

4. |

CHECK CONNECTION BETWEEN TECHSTREAM AND ECM (CAM POSITION SENSOR (FOR INTAKE CAMSHAFT)) |

(a) Disconnect the cam position sensor (for intake camshaft) connector.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

| B |

|

|

|

5. |

CHECK CONNECTION BETWEEN TECHSTREAM AND ECM (CAM POSITION SENSOR (FOR EXHAUST CAMSHAFT)) |

(a) Disconnect the cam position sensor (for exhaust camshaft) connector.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

| B |

|

|

|

6. |

CHECK CONNECTION BETWEEN TECHSTREAM AND ECM (VALVEMATIC SHAFT SENSOR (CAM POSITION SENSOR)) |

(a) Disconnect the VALVEMATIC shaft sensor (cam position sensor) connector.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

| B |

|

|

|

7. |

CHECK CONNECTION BETWEEN TECHSTREAM AND ECM (MANIFOLD ABSOLUTE PRESSURE SENSOR) |

(a) Disconnect the manifold absolute pressure sensor connector.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

| B |

|

|

|

8. |

CHECK CONNECTION BETWEEN TECHSTREAM AND ECM (ACCELERATOR PEDAL POSITION SENSOR) |

(a) Disconnect the accelerator pedal sensor assembly connector.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

| B |

|

|

|

9. |

CHECK CONNECTION BETWEEN TECHSTREAM AND ECM (CANISTER PUMP MODULE) |

(a) Disconnect the canister pump module connector.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

| B |

|

|

|

10. |

CHECK CONNECTION BETWEEN TECHSTREAM AND ECM (MASS AIR FLOW METER SUB-ASSEMBLY) |

(a) Disconnect the mass air flow meter sub-assembly connector.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible (for CVT Models) |

A |

|

Communication is not possible (for Manual Transaxle Models) |

B |

|

Communication is possible |

C |

HINT:

Perform "Inspection After Repair" after replacing the mass air flow meter sub-assembly.

| B |

|

| C |

|

|

|

11. |

CHECK COMMUNICATION BETWEEN THE TECHSTREAM AND ECM (OIL PRESSURE SENSOR) |

(a) Disconnect the oil pressure sensor connector.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

| A |

|

| B |

|

|

12. |

CHECK CONNECTION BETWEEN TECHSTREAM AND ECM (NEUTRAL POSITION SWITCH) |

(a) Disconnect the neutral position switch connector.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Check the communication between the Techstream and ECM.

HINT:

It can be checked using the "Engine and ECT" item of the Data List.

|

Result |

Proceed to |

|---|---|

|

Communication is not possible |

A |

|

Communication is possible |

B |

| B |

|

|

|

13. |

CHECK HARNESS AND CONNECTOR |

(a) Disconnect the throttle body assembly connector.

(b) Disconnect the cam position sensor (for intake camshaft) connector.

(c) Disconnect the cam position sensor (for exhaust camshaft) connector.

(d) Disconnect the manifold absolute pressure sensor connector.

(e) Disconnect the accelerator pedal sensor assembly connector.

(f) Disconnect the mass air flow meter sub-assembly connector.

(g) Disconnect the neutral position switch connector. (for Manual Transaxle models)

(h) Disconnect the oil pressure sensor connector. (for CVT models)

(i) Disconnect the canister pump module connector.

(j) Disconnect the VALVEMATIC shaft sensor (cam position sensor) connector.

(k) Disconnect the ECM connectors.

(l) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C77-134 (VCTA) - Body ground |

Always |

10 kΩ or higher |

|

C77-116 (VCV1) - Body ground |

Always |

10 kΩ or higher |

|

C77-111 (VCE1) - Body ground |

Always |

10 kΩ or higher |

|

C77-77 (VCPM) - Body ground |

Always |

10 kΩ or higher |

|

A46-49 (VCPA) - Body ground |

Always |

10 kΩ or higher |

|

A46-52 (VCP2) - Body ground |

Always |

10 kΩ or higher |

|

C77-103 (VCVG) - Body ground |

Always |

10 kΩ or higher |

|

C77-110 (VCNP)*1 - Body ground |

Always |

10 kΩ or higher |

|

C77-110 (VCPT)*2 - Body ground |

Always |

10 kΩ or higher |

|

A46-55 (VCPP) - Body ground |

Always |

10 kΩ or higher |

|

C77-117 (VCVS) - Body ground |

Always |

10 kΩ or higher |

- *1: for Manual Transaxle models

- *2: for CVT models

(m) Disconnect the No. 1 integration relay connector.

HINT:

Disconnect the No. 1 integration relay (EFI-MAIN relay) connected between the checked terminals as the coil inside the relay influences the measurement value.

(n) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A46-2 (+B) - 1 (EFI NO. 2 fuse) |

Always |

Below 1 Ω |

|

A46-3 (+B2) - 1 (EFI NO. 2 fuse) |

Always |

Below 1 Ω |

|

A46-2 (+B) - Body ground |

Always |

10 kΩ or higher |

|

A46-3 (+B2) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2020 - 2022 MY Corolla [01/2019 - 09/2022]; 2ZR-FAE (ENGINE CONTROL): SFI SYSTEM: ECM Power Source Circuit](/t3Portal/stylegraphics/info.gif)