- DTC judgment completed

- System normal

| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000001GHB4 |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 03/2019] |

| Title: 2ZR-FAE (ENGINE CONTROL): SFI SYSTEM: P265B-P265D; B Rocker Arm Actuator Position Sensor Circuit Range Performance Bank 1; 2020 MY Corolla [01/2019 - 03/2019] | ||

|

DTC |

P265B |

B Rocker Arm Actuator Position Sensor Circuit Range Performance Bank 1 |

|

DTC |

P265C |

B Rocker Arm Actuator Position Sensor Circuit Low Bank 1 |

|

DTC |

P265D |

B Rocker Arm Actuator Position Sensor Circuit High Bank 1 |

DESCRIPTION

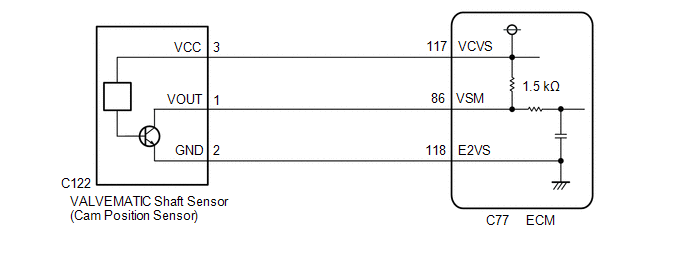

The VALVEMATIC shaft sensor (cam position sensor) detects the position of the shaft monitor target mounted on the VALVEMATIC control shaft and the ECM detects the operation of the VALVEMATIC control shaft.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

|---|---|---|---|---|---|

|

P265B |

B Rocker Arm Actuator Position Sensor Circuit Range Performance Bank 1 |

Either of the following conditions is met: (a) The VALVEMATIC shaft sensor (cam position sensor) voltage is 1.41 V or higher (VALVEMAIC Current Angle is less than 145°CA). (b) The VALVEMATIC shaft sensor (cam position sensor) voltage is less than 3.42 V (VALVEMATIC Current Angle is higher than 223°CA) |

|

Comes on |

DTC stored |

|

P265C |

B Rocker Arm Actuator Position Sensor Circuit Low Bank 1 |

The output voltage of the VALVEMATIC shaft sensor (cam position sensor) is less than 0.38 V for 5 seconds (1 trip detection logic). |

|

Comes on |

DTC stored |

|

P265D |

B Rocker Arm Actuator Position Sensor Circuit High Bank 1 |

The output voltage of the VALVEMATIC shaft sensor (cam position sensor) is higher than 4.68 V for 5 seconds (1 trip detection logic). |

|

Comes on |

DTC stored |

MONITOR DESCRIPTION

If the duration monitored by the continuously variable valve lift controller assembly differs from the VALVEMATIC shaft sensor (cam position sensor) output, or the VALVEMATIC shaft sensor (cam position sensor) voltage is less than 0.38 V, or higher than 4.68 V for 5 seconds or more, the ECM illuminates the MIL and stores a DTC.

MONITOR STRATEGY

|

Related DTCs |

P265B: VALVEMATIC shaft sensor control shaft functionally error P265C: VALVEMATIC shaft sensor range check (low voltage) P265D: VALVEMATIC shaft sensor range check (high voltage) |

|

Required Sensors/Components (Main) |

VALVEMATIC shaft sensor (cam position sensor) |

|

Required Sensors/Components (Related) |

- |

|

Frequency of Operation |

Continuous |

|

Duration |

1 second or less: P265B 5 seconds: P265C and P265D |

|

MIL Operation |

Immediate |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

P265B

|

Monitor runs whenever the following DTCs are not stored |

None |

|

All of the following conditions are met |

- |

|

Engine coolant temperature |

-20°C (-4°F) or higher |

|

Motor activation |

Active |

|

Engine speed |

300 rpm or higher |

|

Battery voltage |

8 V or higher |

P265C and P265D

|

Monitor runs whenever the following DTCs are not stored |

None |

|

All of the following conditions are met |

- |

|

Battery voltage |

8 V or higher |

|

Ignition switch |

ON |

|

Starter |

Off |

TYPICAL MALFUNCTION THRESHOLDS

P265B

|

Either of the following conditions is met |

A or B |

|

A. Both of the following conditions are met |

- |

|

Valve event angle |

Less than 145°CA |

|

VALVEMATIC shaft sensor voltage |

Higher than 1.41 V |

|

B. Both of the following conditions are met |

- |

|

Valve event angle |

Higher than 223°CA |

|

VALVEMATIC shaft sensor voltage |

Less than 3.42 V |

P265C

|

VALVEMATIC shaft sensor voltage |

Less than 0.38 V |

P265D

|

VALVEMATIC shaft sensor voltage |

Higher than 4.68 V |

CONFIRMATION DRIVING PATTERN

- Connect the Techstream to the DLC3.

- Start the engine and warm it up (until the engine coolant temperature 75°C (167°F) or higher).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON.

- Turn the Techstream on.

- Start the engine.

- Idle the engine for 10 seconds or more.

- Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P265B, P265C or P265D.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

-

If the judgment result is INCOMPLETE or N/A and no pending DTC is output, perform a universal trip and check for permanent DTCs.

HINT:

- If a permanent DTC is output, the system is malfunctioning.

- If no permanent DTC is output, the system is normal.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

- Do not disconnect the cable from the negative (-) battery terminal when the power supply of the continuously variable valve lift controller assembly is energized.

-

Because the VALVEMATIC system memorizes settings when the ignition switch is turned off, make sure to wait at least 1 minute after turning the ignition switch off before disconnecting the cable from the negative (-) battery terminal.

If the cable is disconnected from the negative (-) battery terminal when the power supply is energized or within 1 minute after turning the ignition switch off, DTC P265B may be stored.

- Read Freeze Frame Data using the Techstream. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

|

1. |

READ OUTPUT DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

(e) Read the DTCs.

Powertrain > Engine and ECT > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC P265B is output |

A |

|

DTC P265C or P265D is output |

B |

|

DTC P265B, P265C and/or P265D and other DTCs are output |

C |

HINT:

If any DTCs other than P265B, P265C and P265D are output, troubleshoot those DTCs first.

| B |

|

| C |

|

|

|

2. |

CHECK WHETHER DTC OUTPUT RECURS |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Drive the vehicle in accordance with the driving pattern described in Confirmation Driving Pattern.

(e) Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

(f) Read the DTCs.

Powertrain > Engine and ECT > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC P265B is output |

A |

|

DTCs are not output |

B |

| B |

|

END |

|

|

3. |

CLEAR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Clear the DTCs.

Powertrain > Engine and ECT > Clear DTCs

(e) Turn the ignition switch off and wait for at least 30 seconds.

|

|

4. |

PERFORM SIMULATION TEST |

(a) Start the engine and warm it up until the engine coolant temperature reaches 75°C (167°F) or higher.

(b) Idle the engine for 30 seconds or more.

(c) Increase the engine speed to 4000 rpm.

(d) Turn the Techstream on.

(e) Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

(f) Read the DTCs.

Powertrain > Engine and ECT > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs are not output |

A |

|

DTC P265B is output |

B |

| A |

|

|

|

5. |

PERFORM ACTIVE TEST USING TECHSTREAM (ACTIVATE THE VALVEMATIC (ENG ON)) |

(a) Connect the Techstream to the DLC3.

(b) Start the engine and warm it up until the engine coolant temperature stabilizes. (Engine coolant temperature 40°C or higher)

(c) Turn the ignition switch off.

(d) Restart the engine.

HINT:

Do not operate the accelerator pedal.

(e) Turn the Techstream on.

(f) Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VALVEMATIC(ENG ON) / Data List / MAP, Coolant Temp, VALVEMATIC Target Angle, VALVEMATIC Current Angle, VALVEMATIC bef Warm Up.

Powertrain > Engine and ECT > Active Test

|

Active Test Display |

|---|

|

Activate the VALVEMATIC(ENG ON) |

|

Data List Display |

|---|

|

MAP |

|

Coolant Temp |

|

VALVEMATIC Target Angle |

|

VALVEMATIC Current Angle |

|

VALVEMATIC bef Warm Up |

(g) Check the Data List "VALVEMATIC bef Warm Up" display is "ON".

HINT:

If "VALVEMATIC bef Warm Up" is not "ON".

- Restart the engine. (Do not operate the accelerator pedal.)

- Perform the Active Test "Activate the VALVEMATIC before Warm Up" to set "VALVEMATIC bef Warm Up" to "ON". (Do not operate the accelerator pedal.)

(h) Set the Active Test "Activate the VALVEMATIC(ENG ON)" to "High" and check that "VALVEMATIC Current Angle" follows "VALVEMATIC Target Angle" and the "MAP" value changes.

Standard:

|

Techstream Operation |

Result |

|---|---|

|

High |

VALVEMATIC Current Angle: 260 deg(CA) MAP: 25 to 40 kPa (3.6 to 5.8 psi) |

(i) Set the Active Test "Activate the VALVEMATIC(ENG ON)" to "OFF", and check that "VALVEMATIC bef Warm Up" returns to "ON".

(j) Set the Active Test "Activate the VALVEMATIC(ENG ON)" to "Low" and check that "VALVEMATIC Current Angle" follows "VALVEMATIC Target Angle" and the "MAP" value changes.

Standard:

|

Techstream Operation |

Result |

|---|---|

|

Low |

VALVEMATIC Current Angle: 106 deg(CA) MAP: 35 to 65 kPa (5.1 to 9.4 psi) |

OK:

When performing the Active Test, "VALVEMATIC Current Angle" follows "VALVEMATIC Target Angle" and the "MAP" value changes.

HINT:

- After the accelerator pedal is depressed and the Active Test operates once to "Low", "VALVEMATIC bef Warm Up" does not return to "ON". Therefore, in order to repeat the inspection, it is necessary to either perform the Active Test "Activate the VALVEMATIC before Warm Up" to set the VALVEMATIC system to the operating position that occurs before the engine is warmed up, or restart the engine.

- When the vehicle is driven while there is a malfunction in the VALVEMATIC system and the valve lift amount is fixed at the minimum, the vehicle speed cannot exceed 30 to 60 km/h (19 to 37 mph).

- If the intake valve advance angle is within the VALVEMATIC operation prohibition range depending on the operating state of the VVT system, the Active Test "Activate the VALVEMATIC(ENG ON)" is prohibited. If the advance angle cannot be detected due to a malfunction in the VVT system, the Active Test "Activate the VALVEMATIC(ENG ON)" is prohibited.

| NG |

|

REPLACE CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER ASSEMBLY |

|

|

6. |

INSPECT CAMSHAFT HOUSING SUB-ASSEMBLY |

(a) Inspect the shaft monitor target.

OK:

The shaft monitor target is free of foreign matter and installed correctly.

HINT:

Perform "Inspection After Repair" after replacing the camshaft housing sub-assembly.

| NG |

|

|

|

7. |

INSPECT VALVE LIFT CONTROL ACTUATOR CONNECTOR |

(a) Inspect the valve lift control actuator connector.

OK:

Valve lift control actuator connector is installed correctly.

HINT:

Perform "Inspection After Repair" after replacing the continuously variable valve lift controller assembly.

| OK |

|

| NG |

|

REPLACE CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER ASSEMBLY |

|

8. |

CHECK HARNESS AND CONNECTOR |

|

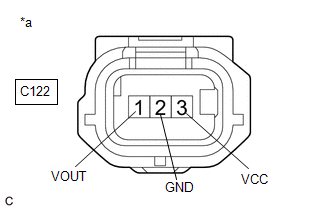

*a |

Front view of wire harness connector (to VALVEMATIC Shaft Sensor (Cam Position Sensor)) |

HINT:

Make sure that the connector is properly connected. If it is not, securely connect it and check for DTCs again.

(a) Disconnect the VALVEMATIC shaft sensor (cam position sensor) connector.

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C122-3 (VCC) - Body ground |

Ignition switch ON |

4.5 to 5.5 V |

|

C122-1 (VOUT) - Body ground |

Ignition switch ON |

3.0 to 5.0 V |

(d) Turn the ignition switch off and wait for at least 30 seconds.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C122-3 (VCC) - C122-1 (VOUT) |

Ignition switch off |

1.425 to 1.575 kΩ |

|

C122-2 (GND) - Body ground |

Always |

Below 1 Ω |

| NG |

|

|

|

9. |

CHECK SENSOR INSTALLATION AND CONDUCT VISUAL INSPECTION (VALVEMATIC SHAFT SENSOR (CAM POSITION SENSOR)) |

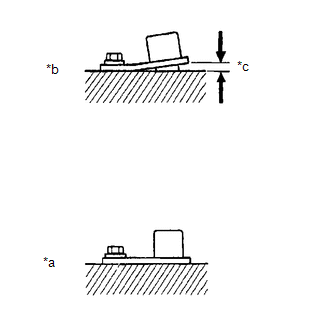

|

*a |

OK |

|

*b |

NG |

|

*c |

Clearance |

(a) Visually check the VALVEMATIC shaft sensor (cam position sensor) for damage.

(b) Check the VALVEMATIC shaft sensor (cam position sensor) installation.

OK:

VALVEMATIC shaft sensor (cam position sensor) does not have any damage and is installed properly.

| OK |

|

| NG |

|

SECURELY REINSTALL VALVEMATIC SHAFT SENSOR (CAM POSITION SENSOR) |

|

10. |

CHECK HARNESS AND CONNECTOR (VALVEMATIC SHAFT SENSOR (CAM POSITION SENSOR) - ECM) |

(a) Disconnect the VALVEMATIC shaft sensor (cam position sensor) connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C122-1 (VOUT) - C77-86 (VSM) |

Always |

Below 1 Ω |

|

C122-2 (GND) - C77-118 (E2VS) |

Always |

Below 1 Ω |

|

C122-3 (VCC) - C77-117 (VCVS) |

Always |

Below 1 Ω |

|

C122-1 (VOUT) or C77-86 (VSM) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C122-2 (GND) or C77-118 (E2VS) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C122-3 (VCC) or C77-117 (VCVS) - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2020 MY Corolla [01/2019 - 03/2019]; 2ZR-FAE (ENGINE CONTROL): SFI SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)