- DTC judgment completed

- System normal

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001GHAW |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 03/2019] |

| Title: 2ZR-FAE (ENGINE CONTROL): SFI SYSTEM: P2120-P2123,P2125,P2127,P2128,P2138; Throttle / Pedal Position Sensor / Switch "D" Circuit; 2020 MY Corolla [01/2019 - 03/2019] | ||

|

DTC |

P2120 |

Throttle / Pedal Position Sensor / Switch "D" Circuit |

|

DTC |

P2121 |

Throttle / Pedal Position Sensor / Switch "D" Circuit Range / Performance |

|

DTC |

P2122 |

Throttle / Pedal Position Sensor / Switch "D" Circuit Low Input |

|

DTC |

P2123 |

Throttle / Pedal Position Sensor / Switch "D" Circuit High Input |

|

DTC |

P2125 |

Throttle / Pedal Position Sensor / Switch "E" Circuit |

|

DTC |

P2127 |

Throttle / Pedal Position Sensor / Switch "E" Circuit Low Input |

|

DTC |

P2128 |

Throttle / Pedal Position Sensor / Switch "E" Circuit High Input |

|

DTC |

P2138 |

Throttle / Pedal Position Sensor / Switch "D" / "E" Voltage Correlation |

DESCRIPTION

HINT:

These DTCs relate to the accelerator pedal position sensor.

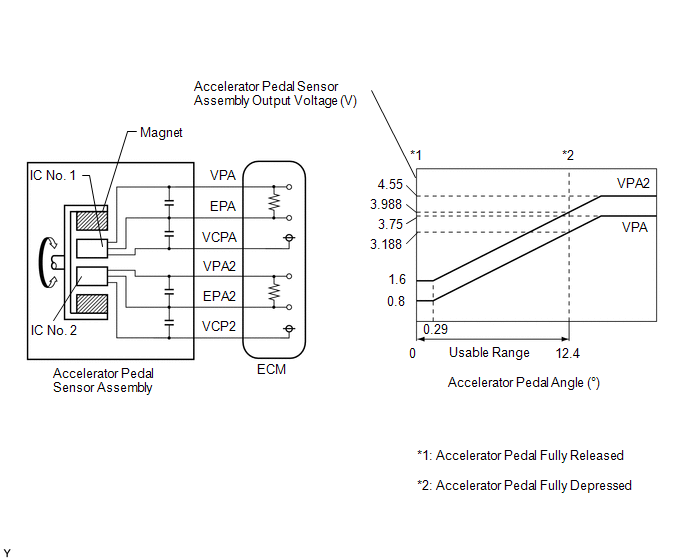

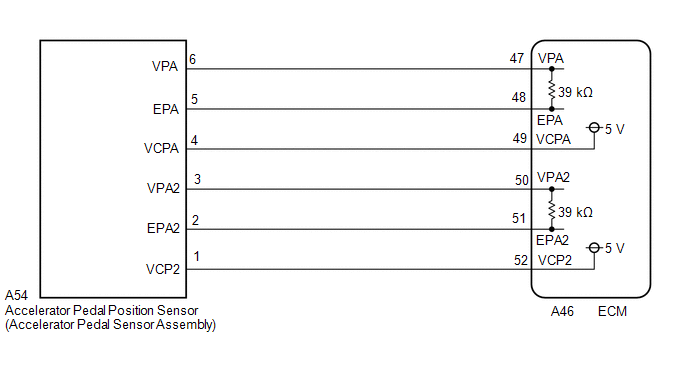

The accelerator pedal position sensor is built into the accelerator pedal sensor assembly and has 2 sensor circuits: VPA (main) and VPA2 (sub). This sensor is a non-contact type sensor and uses Hall-effect elements in order to yield accurate signals even in extreme driving conditions, such as at high speeds as well as very low speeds. The voltage, which is applied to terminals VPA and VPA2 of the ECM, varies between 0.5 V and 4.75 V in proportion to the operating angle of the accelerator pedal (throttle valve). A signal from VPA indicates the actual accelerator pedal opening angle (throttle valve opening angle) and is used for engine control. A signal from VPA2 conveys the status of the VPA circuit and is used to check the accelerator pedal position sensor itself.

The ECM monitors the actual accelerator pedal opening angle (throttle valve opening angle) through the signals from VPA and VPA2, and controls the throttle actuator according to these signals.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

|---|---|---|---|---|---|

|

P2120 |

Throttle / Pedal Position Sensor / Switch "D" Circuit |

VPA fluctuates rapidly beyond the upper and lower malfunction thresholds for 0.5 seconds or more (1 trip detection logic). |

|

Comes on |

DTC stored |

|

P2121 |

Throttle / Pedal Position Sensor / Switch "D" Circuit Range / Performance |

Either of the following conditions is met (1 trip detection logic):

|

|

Comes on |

DTC stored |

|

P2122 |

Throttle / Pedal Position Sensor / Switch "D" Circuit Low Input |

VPA is 0.4 V or less for 0.5 seconds or more when the accelerator pedal is depressed (1 trip detection logic). |

|

Comes on |

DTC stored |

|

P2123 |

Throttle / Pedal Position Sensor / Switch "D" Circuit High Input |

VPA is 4.8 V or higher for 2.0 seconds or more (1 trip detection logic). |

|

Comes on |

DTC stored |

|

P2125 |

Throttle / Pedal Position Sensor / Switch "E" Circuit |

VPA2 fluctuates rapidly beyond the upper and lower malfunction thresholds for 0.5 seconds or more (1 trip detection logic). |

|

Comes on |

DTC stored |

|

P2127 |

Throttle / Pedal Position Sensor / Switch "E" Circuit Low Input |

VPA2 is 1.2 V or less for 0.5 seconds or more when the accelerator pedal is depressed (1 trip detection logic). |

|

Comes on |

DTC stored |

|

P2128 |

Throttle / Pedal Position Sensor / Switch "E" Circuit High Input |

Both of the following conditions continue for 2.0 seconds or more (1 trip detection logic): (a) VPA2 is 4.8 V or higher. (b) VPA is between 0.4 V and 3.45 V. |

|

Comes on |

DTC stored |

|

P2138 |

Throttle / Pedal Position Sensor / Switch "D" / "E" Voltage Correlation |

Either of the following conditions continues for 2.0 seconds or more (1 trip detection logic): (a) The difference between VPA and VPA2 is 0.02 V or less. (b) VPA is 0.4 V or less, and VPA2 is 1.2 V or less. |

|

Comes on |

DTC stored |

HINT:

When any of these DTCs are output, check the accelerator pedal position sensor voltage using the Techstream. Enter the following menus: Powertrain / Engine and ECT / Data List / Accel Sensor Out No.1 and Accel Sensor Out No.2.

|

Trouble Area |

Accelerator Pedal Fully Released |

Accelerator Pedal Fully Depressed |

||

|---|---|---|---|---|

|

Accel Sensor Out No.1 |

Accel Sensor Out No.2 |

Accel Sensor Out No.1 |

Accel Sensor Out No.2 |

|

|

Open in VCP circuit |

0 to 0.2 V |

0 to 0.2 V |

0 to 0.2 V |

0 to 0.2 V |

|

Open or ground short in VPA circuit |

0 to 0.2 V |

1.2 to 2.0 V |

0 to 0.2 V |

3.4 to 4.75 V |

|

Open or ground short in VPA2 circuit |

0.5 to 1.1 V |

0 to 0.2 V |

2.6 to 4.5 V |

0 to 0.2 V |

|

Open in EPA circuit |

4.5 to 4.98 V |

4.5 to 4.98 V |

4.5 to 4.98 V |

4.5 to 4.98 V |

|

Normal condition |

0.5 to 1.1 V |

1.2 to 2.0 V |

2.6 to 4.5 V |

3.4 to 4.75 V |

HINT:

Accelerator pedal positions are expressed as voltages.

MONITOR DESCRIPTION

When either output voltage of VPA or VPA2 deviates from the standard range, or the difference between the output voltages of the 2 sensor circuits is more than the threshold, the ECM determines that there is a malfunction in the accelerator pedal position sensor. The ECM then illuminates the MIL and stores a DTC.

Example:

When the output voltage of VPA is 0.4 V or less for 0.5 seconds or more when the accelerator pedal is fully depressed, DTC P2122 is stored.

MONITOR STRATEGY

|

Related DTCs |

P2120: Accelerator pedal position sensor 1 range check (chattering) P2121: Accelerator pedal position sensor rationality P2122: Accelerator pedal position sensor 1 range check (low voltage) P2123: Accelerator pedal position sensor 1 range check (high voltage) P2125: Accelerator pedal position sensor 2 range check (chattering) P2127: Accelerator pedal position sensor 2 range check (low voltage) P2128: Accelerator pedal position sensor 2 range check (high voltage) P2138: Accelerator pedal position sensor range check (correlation) |

|

Required Sensors/Components (Main) |

Accelerator pedal sensor assembly |

|

Required Sensors/Components (Related) |

- |

|

Frequency of Operation |

Continuous |

|

Duration |

0.5 seconds: P2120, P2121 (Case 2), P2122, P2125 and P2127 2.0 seconds: P2123, P2128 and P2138 -: P2121 (Case 1) |

|

MIL Operation |

Immediate |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

P2120, P2122, P2123, P2125, P2127, P2128 and P2138

|

Monitor runs whenever the following DTCs are not stored |

None |

|

Either of the following conditions is met |

A or B |

|

A. Time after ignition switch off to ON |

0.012 seconds or more |

|

B. Command to electronic throttle actuator power |

On |

P2121

|

All of the following conditions is met |

- |

|

Either of the following conditions is met |

A or B |

|

A. Time after ignition switch off to ON |

0.012 seconds or more |

|

B. Command to electronic throttle actuator power |

On |

|

Accelerator pedal position sensor circuit fail (P2120, P2122, P2123, P2125, P2127, P2128, P2138) |

Not detected |

TYPICAL MALFUNCTION THRESHOLDS

P2120

|

Either of the following conditions is met |

1 or 2 |

|

1. Both of the following conditions are met |

- |

|

VPA voltage |

0.4 V or less |

|

VPA2 voltage - Learned VPA2 accelerator off position voltage |

0.04 V or higher |

|

2. VPA voltage |

4.8 V or higher |

P2121 (Case 1)

|

Difference between VPA voltage and VPA2 voltage (learned value of accelerator off position) |

Less than 0.4 V, or higher than 1.2 V |

P2121 (Case 2)

|

All of the following conditions are met |

- |

|

[(VPA voltage - Learned VPA accelerator off position voltage) - (VPA2 voltage - Learned VPA2 accelerator off position voltage)] |

0.165 V or higher (varies with accelerator position) |

|

VPA2 voltage |

Less than 4.84 V |

|

Either of the following conditions met |

a or b |

|

a) VPA voltage - Learned VPA accelerator off position voltage |

0.04 V or higher |

|

b) VPA2 voltage - Learned VPA2 accelerator off position voltage |

0.04 V or higher |

P2122

|

Both of the following conditions are met |

- |

|

VPA voltage |

0.4 V or less |

|

VPA2 voltage - Learned VPA2 accelerator off position voltage |

0.04 V or higher |

P2123

|

VPA voltage |

4.8 V or higher |

P2125

|

Either of the following conditions is met |

1 or 2 |

|

1. Both of the following conditions are met |

- |

|

VPA2 voltage |

1.2 V or less |

|

VPA voltage - Learned VPA accelerator off position voltage |

0.04 V or higher |

|

2. VPA2 voltage when VPA voltage 0.4 to 3.45 V |

4.8 V or higher |

P2127

|

Both of the following conditions are met |

- |

|

VPA2 voltage |

1.2 V or less |

|

VPA voltage - Learned VPA accelerator off position voltage |

0.04 V or higher |

P2128

|

VPA2 voltage when VPA voltage 0.4 to 3.45 V |

4.8 V or higher |

P2138

|

Either of the following conditions is met |

A or B |

|

A. Difference between VPA and VPA2 voltages |

0.02 V or less |

|

B. Both of the following conditions are met |

- |

|

VPA voltage |

0.4 V or less |

|

VPA2 voltage |

1.2 V or less |

COMPONENT OPERATING RANGE

|

All of the following conditions are met |

- |

|

VPA voltage |

Higher than 0.4 V, and less than 4.8 V |

|

VPA2 voltage |

Higher than 1.2 V, and less than 4.8 V |

|

Difference between VPA and VPA2 voltages |

Higher than 0.02 V |

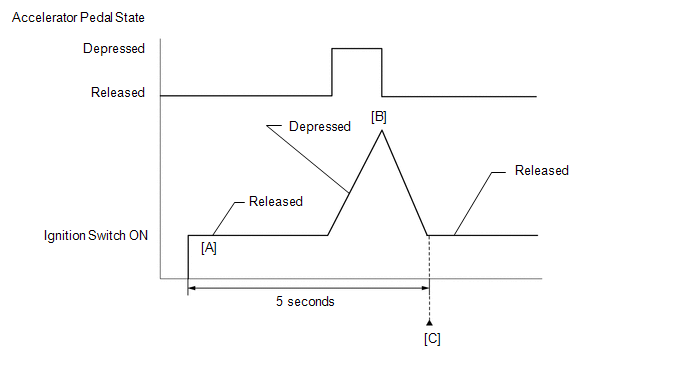

CONFIRMATION DRIVING PATTERN

P2120, P2122, P2123, P2125, P2127, P2128, P2138

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON.

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON [A].

- Turn the Techstream on.

- Fully depress and release the accelerator pedal [B].

- Check that 5 seconds or more have elapsed since the ignition switch is turned to ON.

- Enter the following menus: Powertrain / Engine and ECT / Trouble Codes [C].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P2120, P2122, P2123, P2125, P2127, P2128 or P2138.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform steps [B] through [C] again.

-

If no pending DTC is output, perform a universal trip and check for permanent DTCs.

HINT:

- If a permanent DTC is output, the system is malfunctioning.

- If no permanent DTC is output, the system is normal.

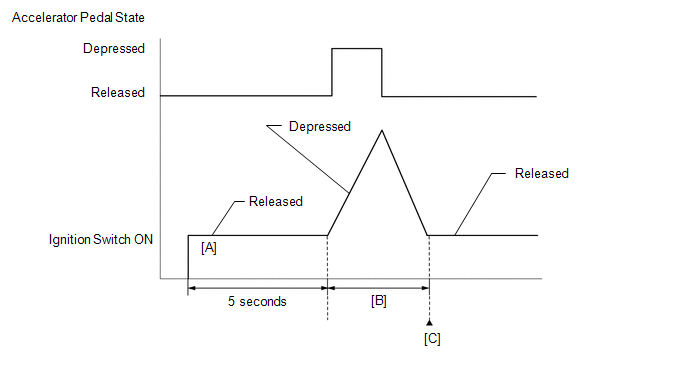

P2121

- Connect the Techstream to the DLC3.

- Turn the ignition switch to ON.

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for at least 30 seconds.

- Turn the ignition switch to ON [A].

- Turn the Techstream on.

- Wait for 5 seconds after turning the ignition switch turned to ON.

-

Operate the accelerator pedal in accordance with the following procedure [B].

- Enter the following menus: Powertrain / Engine and ECT / Data List / Accel Sens. No.1 Volt %, and Accel Sens. No.2 Volt %.

- Slowly depress the accelerator pedal until Accel Sens. No.1 Volt % is approximately 30% and Accel Sens. No.2 Volt % is approximately 46%, then slowly release the accelerator pedal.

- Enter the following menus: Powertrain / Engine and ECT / Trouble Codes [C].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

- Input the DTC: P2121.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform steps [B] through [C] again.

-

If no pending DTC is output, perform a universal trip and check for permanent DTCs.

HINT:

- If a permanent DTC is output, the system is malfunctioning.

- If no permanent DTC is output, the system is normal.

FAIL-SAFE

When these DTCs are stored, the ECM enters fail-safe mode. If either of the 2 sensor circuits malfunctions, the ECM limits the engine output. If both of the circuits malfunction, the ECM regards the accelerator pedal as being released. As a result, the throttle valve is closed and the engine idles.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is turned off.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

HINT:

Read Freeze Frame Data using the Techstream. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (ACCEL SENSOR OUT NO. 1 AND NO. 2) |

|

(a) Connect the Techstream to the DLC3. |

|

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine and ECT / Data List / Accel Sensor Out No.1 and Accel Sensor Out No.2.

Powertrain > Engine and ECT > Data List

|

Tester Display |

|---|

|

Accel Sensor Out No.1 |

|

Accel Sensor Out No.2 |

(e) Read the value displayed on the Techstream.

Standard Voltage:

|

Accelerator Pedal Operation |

Accel Sensor Out No.1 |

Accel Sensor Out No.2 |

Difference between Accel Sensor Out No.1 and Accel Sensor Out No.2 |

|---|---|---|---|

|

Fully Released |

0.5 to 1.1 V |

1.2 to 2.0 V |

More than 0.02 V |

|

Fully Depressed |

2.6 to 4.5 V |

3.4 to 4.75 V |

| OK |

|

|

|

2. |

CHECK TERMINAL VOLTAGE (POWER SOURCE OF ACCELERATOR PEDAL SENSOR ASSEMBLY) |

|

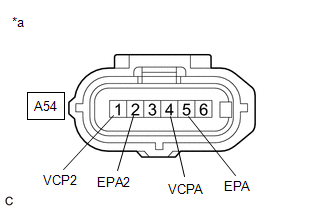

*a |

Front view of wire harness connector (to Accelerator Pedal Sensor Assembly) |

HINT:

Make sure that the connector is properly connected. If it is not, securely connect it and check for DTCs again.

(a) Disconnect the accelerator pedal sensor assembly connector.

(b) Turn the ignition switch to ON.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A54-4 (VCPA) - A54-5 (EPA) |

Ignition switch ON |

4.5 to 5.5 V |

|

A54-1 (VCP2) - A54-2 (EPA2) |

Ignition switch ON |

4.5 to 5.5 V |

| NG |

|

|

|

3. |

CHECK HARNESS AND CONNECTOR (RESISTANCE OF ECM) |

|

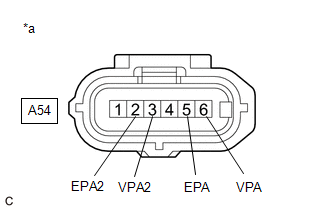

*a |

Front view of wire harness connector (to Accelerator Pedal Sensor Assembly) |

(a) Disconnect the accelerator pedal sensor assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A54-6 (VPA) - A54-5 (EPA) |

Ignition switch off |

37.05 to 40.95 kΩ |

|

A54-3 (VPA2) - A54-2 (EPA2) |

Ignition switch off |

37.05 to 40.95 kΩ |

| OK |

|

|

|

4. |

CHECK HARNESS AND CONNECTOR (ACCELERATOR PEDAL SENSOR ASSEMBLY - ECM) |

(a) Disconnect the accelerator pedal sensor assembly connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A54-6 (VPA) - A46-47 (VPA) |

Always |

Below 1 Ω |

|

A54-5 (EPA) - A46-48 (EPA) |

Always |

Below 1 Ω |

|

A54-3 (VPA2) - A46-50 (VPA2) |

Always |

Below 1 Ω |

|

A54-2 (EPA2) - A46-51 (EPA2) |

Always |

Below 1 Ω |

|

A54-6 (VPA) or A46-47 (VPA) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

A54-5 (EPA) or A46-48 (EPA) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

A54-3 (VPA2) or A54-50 (VPA2) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

A54-2 (EPA2) or A46-51 (EPA2) - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

5. |

CHECK HARNESS AND CONNECTOR (ACCELERATOR PEDAL SENSOR ASSEMBLY - ECM) |

(a) Disconnect the accelerator pedal sensor assembly connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A54-4 (VCPA) - A46-49 (VCPA) |

Always |

Below 1 Ω |

|

A54-5 (EPA) - A46-48 (EPA) |

Always |

Below 1 Ω |

|

A54-1 (VCP2) - A46-52 (VCP2) |

Always |

Below 1 Ω |

|

A54-2 (EPA2) - A46-51 (EPA2) |

Always |

Below 1 Ω |

|

A54-4 (VCPA) or A46-49 (VCPA) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

A54-5 (EPA) or A46-48 (EPA) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

A54-1 (VCP2) or A46-52 (VCP2) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

A54-2 (EPA2) or A46-51 (EPA2) - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2020 MY Corolla [01/2019 - 03/2019]; 2ZR-FAE (ENGINE CONTROL): SFI SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)