| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001GCPF |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - ] |

| Title: HYBRID / BATTERY CONTROL: COOLANT (for Inverter): ON-VEHICLE INSPECTION; 2020 - 2025 MY Corolla Corolla HV [01/2019 - ] | ||

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

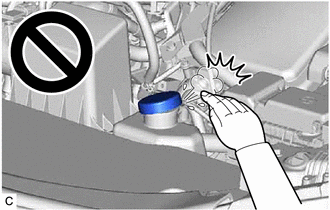

CAUTION:

To avoid the danger of being burned, do not remove the reserve tank cap while the coolant (for inverter) is still hot. Pressurized, hot coolant (for inverter) and steam may be released and cause serious burns.

PROCEDURE

1. INSPECT FOR COOLANT LEAK (for Inverter)

CAUTION:

To avoid the danger of being burned, do not remove the reserve tank cap while the coolant (for inverter) is still hot. Pressurized, hot coolant (for inverter) and steam may be released and cause serious burns.

(a) Remove the reserve tank cap from the inverter reserve tank assembly.

(b) Add coolant to the FULL line of the inverter reserve tank assembly.

|

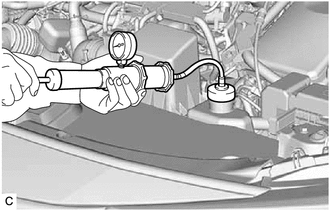

(c) Install the radiator cap tester to the inverter reserve tank assembly. |

|

(d) Pump the radiator cap tester to 122 kPa (1.2 kgf/ cm2, 18 psi), and then check that the pressure does not drop.

HINT:

If the pressure drops, check the hoses, radiator assembly, inverter water pump assembly, hybrid vehicle transaxle assembly and inverter with converter assembly for leaks.

(e) Reinstall the reserve tank cap to the inverter reserve tank assembly.

2. INSPECT COOLANT LEVEL IN RESERVE TANK (for Inverter)

|

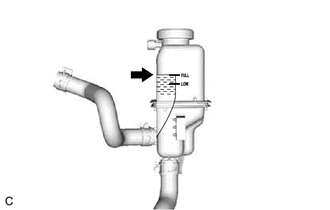

(a) The coolant (for inverter) should be between the LOW and FULL lines when the coolant (for inverter) is cold. HINT: If the coolant level is low, check for leaks and add TOYOTA Super Long Life Coolant (SLLC) or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, and non-borate coolant with long-life hybrid organic acid technology up to the FULL line. |

|

3. INSPECT COOLANT QUALITY (for Inverter)

CAUTION:

To avoid the danger of being burned, do not remove the reserve tank cap while the coolant (for inverter) is still hot. Pressurized, hot coolant (for inverter) and steam may be released and cause serious burns.

(a) Remove the reserve tank cap from the inverter reserve tank assembly.

(b) Check for excessive deposits of rust or scale on and around the reserve tank cap and its opening.

HINT:

If excessively dirty, replace the coolant (for inverter).

(c) Reinstall the reserve tank cap to the inverter reserve tank assembly.

4. INSPECT RESERVE TANK CAP (for Inverter)

|

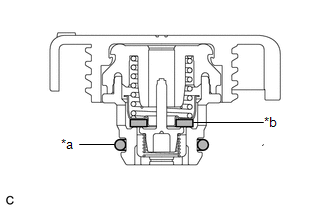

(a) Inspect the reserve tank cap. (1) If there are water stains or foreign matter on the O-ring, clean it with water and finger scouring. NOTICE: Do not use any tools. (2) Check that the O-ring is not deformed, cracked, or damaged. (3) Check that the O-ring is not swollen. |

|

|

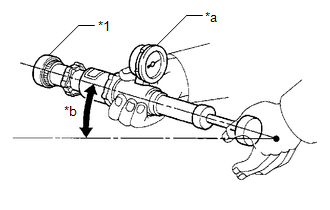

(b) Check the reserve tank cap operation. (1) Apply coolant to the O-ring and rubber packing before using a radiator cap tester. (2) Install the reserve tank cap to the radiator cap tester. (3) Pump the radiator cap tester several times and check the maximum pressure. Judgment Criterion

NOTICE: When using the radiator cap tester, tilt it upward 30° or more. If the maximum pressure is less than the minimum standard value, replace the reserve tank cap. |

|

|

|

|