- Hybrid/EV Battery Current for Hybrid/EV Battery Control*1

- Hybrid/EV Battery Current

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001GCN0 |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 09/2022] |

| Title: HYBRID / BATTERY CONTROL: HYBRID CONTROL SYSTEM (for NICKEL METAL HYDRIDE BATTERY): P0ABF28; Hybrid/EV Battery Current Sensor "A" Signal Bias Level Out of Range / Zero Adjustment Failure; 2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022] | ||

|

DTC |

P0ABF28 |

Hybrid/EV Battery Current Sensor "A" Signal Bias Level Out of Range / Zero Adjustment Failure |

DESCRIPTION

Refer to the description for DTC P0ABF11.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Warning Indicate |

|---|---|---|---|---|---|

|

P0ABF28 |

Hybrid/EV Battery Current Sensor "A" Signal Bias Level Out of Range / Zero Adjustment Failure |

The offset value of the battery current sensor is excessively large. (1 trip detection logic) |

|

Comes on |

Master Warning: Comes on |

Related Data List

|

DTC No. |

Data List |

|---|---|

|

P0ABF28 |

|

HINT:

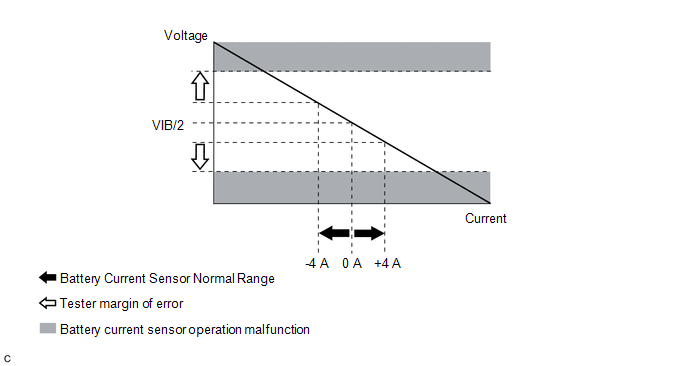

*1: The value of "Hybrid/EV Battery Current for Hybrid/EV Battery Control" usually changes by 4 A or more while the vehicle is accelerating and decelerating.

MONITOR DESCRIPTION

If the battery voltage sensor detects a malfunction in the battery current sensor, the hybrid vehicle control ECU will illuminate the MIL and store a DTC.

MONITOR STRATEGY

|

Related DTCs |

P0AC0 (INF P0ABF28): Current sensor malfunction |

|

Required sensors/components |

Battery current sensor |

|

Frequency of operation |

Continuous |

|

Duration |

TMC's intellectual property |

|

MIL operation |

1 driving cycle |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

|

The monitor will run whenever the following DTCs are not stored |

TMC's intellectual property |

|

Other conditions belong to TMC's intellectual property |

- |

TYPICAL MALFUNCTION THRESHOLDS

|

TMC's intellectual property |

- |

COMPONENT OPERATING RANGE

|

Battery voltage sensor |

DTC P0AC0 (INF P0ABF28) is not detected |

CONFIRMATION DRIVING PATTERN

HINT:

- Connect the Techstream to the DLC3.

- Turn the power switch on (IG) and turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the power switch off and wait for 2 minutes or more.

- Drive the vehicle on urban roads for approximately 10 minutes.[*1]

- Turn the power switch off and wait for 2 minutes or more.[*2]

- Turn the power switch on (IG) and turn the Techstream on.[*3]

-

With power switch on (IG) and wait for 10 seconds or more.[*4]

HINT:

[*1] to [*4]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Powertrain / Hybrid Control / Utility / All Readiness.

-

Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to the wiring diagram for DTC P0ABF11.

CAUTION / NOTICE / HINT

CAUTION:

-

Before the following operations are conducted, take precautions to prevent electric shock by turning the power switch off, wearing insulated gloves, and removing the service plug grip from HV battery.

- Inspecting the high-voltage system

- Disconnecting the low voltage connector of the inverter with converter assembly

- Disconnecting the low voltage connector of the HV battery

-

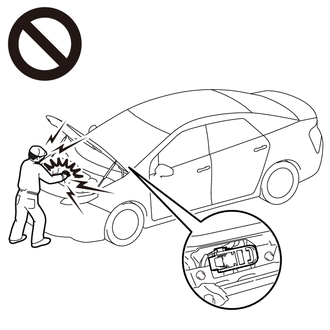

To prevent electric shock, make sure to remove the service plug grip to cut off the high voltage circuit before servicing the vehicle.

-

After removing the service plug grip from the HV battery, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

-

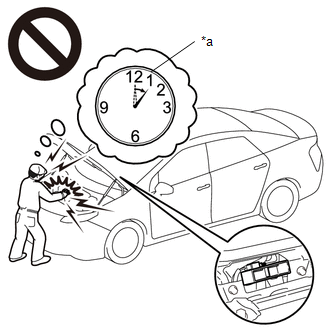

After removing the service plug grip, wait for at least 10 minutes before touching any of the high-voltage connectors or terminals. After waiting for 10 minutes, check the voltage at the terminals in the inspection point in the inverter with converter assembly. The voltage should be 0 V before beginning work.

*a

Without waiting for 10 minutes

HINT:

Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with converter assembly.

NOTICE:

After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

PROCEDURE

|

1. |

CHECK DTC OUTPUT (HYBRID CONTROL) |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

(d) Check for DTCs.

Powertrain > Hybrid Control > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

P0AFC00, P0AFC96 or P0A9563 is not output. |

A |

|

P0AFC00, P0AFC96 or P0A9563 is output. |

B |

(e) Turn the power switch off.

| B |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (BATTERY VOLTAGE SENSOR - HV BATTERY JUNCTION BLOCK ASSEMBLY) |

| NG |

|

|

|

3. |

CHECK HV BATTERY JUNCTION BLOCK ASSEMBLY (BATTERY CURRENT SENSOR (IB)) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Remove the No. 1 hybrid battery exhaust duct.

(c) Connect the cable to the negative (-) auxiliary battery terminal.

(d) Turn the power switch on (IG).

|

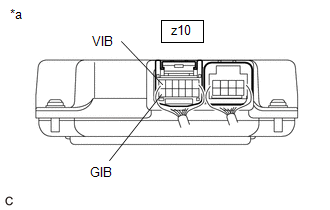

(e) Using a toyota electrical tester set to 40 V, measure the VIB voltage according to the value(s) in the table below.

NOTICE:

|

|

|

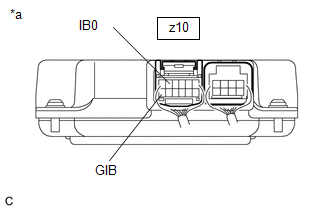

(f) Using a toyota electrical tester set to 4 V, measure the IB0 voltage according to the value(s) in the table below.

NOTICE: Be sure to set the toyota electrical tester to 4 V when performing this test. |

|

(g) Compare the measured values of the IB0 terminal voltage and VIB terminal voltage using the following formula:

|

IB0 voltage - VIB Voltage / 2 = less than 0.081 V |

|

IB0 voltage - VIB Voltage / 2 = -0.081 V or higher |

|

Result |

Proceed to |

|---|---|

|

Within the specified range above |

A |

|

Other than above |

B |

(h) Turn the power switch off.

(i) Disconnect the cable from the negative (-) auxiliary battery terminal.

(j) Install the No. 1 hybrid battery exhaust duct.

HINT:

When the power switch is on (IG) the actual current will be approximately 0 A. The following graph shows the relation of the actual output voltage of the battery current sensor terminal IB0 and actual current used for DTC judgment.

| B |

|

|

|

4. |

REPLACE BATTERY VOLTAGE SENSOR |

|

|

5. |

SIMULATION TEST |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

(d) Clear the DTCs and freeze frame data.

Powertrain > Hybrid Control > Clear DTCs

(e) Drive the vehicle on urban roads for approximately 10 minutes.

(f) Turn the power switch off and wait for 2 minutes or more.

(g) Turn the power switch on (IG) and wait for 10 seconds or more.

|

|

6. |

RECONFIRM DTC OUTPUT (HYBRID CONTROL) |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

(d) Read output DTCs.

Powertrain > Hybrid Control > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

P0ABF28 is not output. |

A |

|

P0ABF28 is output. |

B |

(e) Turn the power switch off.

| A |

|

END |

| B |

|

|

|

|

![2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022]; HYBRID / BATTERY CONTROL: HYBRID CONTROL SYSTEM (for NICKEL METAL HYDRIDE BATTERY): P0ABF11,P0ABF15,P1CBB12,P1CBB14; Hybrid/EV Battery Current Sensor "A" Circuit Short to Ground+](/t3Portal/stylegraphics/info.gif)