| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000001G78U |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 09/2022] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for HV Model): C1247,C1392; Stroke Sensor; 2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022] | ||

|

DTC |

C1247 |

Stroke Sensor |

|

DTC |

C1392 |

Zero Point Calibration of Stroke Sensor undone |

DESCRIPTION

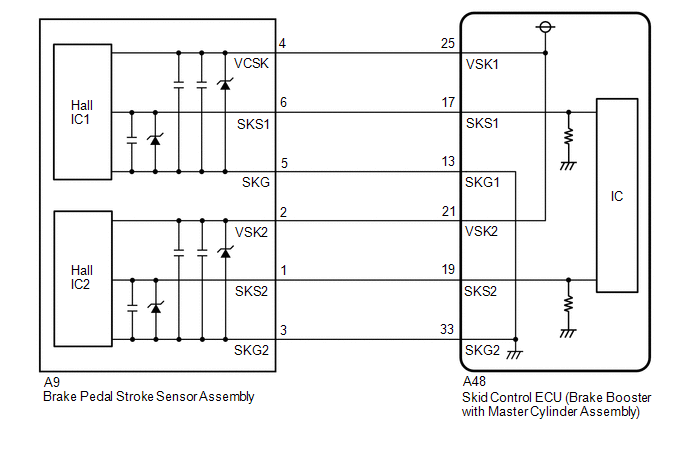

The brake pedal stroke sensor assembly sends a signal about the pedal stroke to the skid control ECU (brake booster with master cylinder assembly).

|

DTC No. |

Detection Item |

INF Code |

DTC Detection Condition |

Trouble Area |

MIL |

Note |

|---|---|---|---|---|---|---|

|

C1247 |

Stroke Sensor |

211 212 213 214 215 216 217 |

|

|

Comes on |

|

|

C1392 |

Zero Point Calibration of Stroke Sensor undone |

1124 |

The brake pedal stroke sensor assembly zero point calibration is not performed. (Normal brake pedal stroke sensor assembly zero point not memorized.) |

Normal brake pedal stroke sensor assembly zero point not memorized. (Linear solenoid valve offset learning is not performed or Test Mode is not performed or not complete.) |

Only DTC C1392 (INF code 1124) is stored: Does not come on SAE Code C1392 is stored: Comes on |

HINT: During Test Mode, related DTCs are cleared (except SAE code). |

MONITOR DESCRIPTION

C0562:

- The skid control ECU (brake booster with master cylinder assembly) monitors the power supply voltage of the brake pedal stroke sensor assembly. When the brake pedal stroke sensor assembly power supply voltage is outside of the normal range, the skid control ECU (brake booster with master cylinder assembly) judges that the power supply is abnormal and illuminates the MIL and stores this DTC.

C124B:

-

When the following conditions are met, the skid control ECU (brake booster with master cylinder assembly) judges that the data from the brake pedal stroke sensor assembly is invalid and illuminates the MIL and stores this DTC.

- Brake pedal stroke sensor assembly related DTCs (C0562, P057D, P05DE, P057C, P05DD, P05E0, P057E and P05DF) are not stored.

- When related malfunction DTCs are not stored, the skid control ECU (brake booster with master cylinder assembly) continuously detects a brake pedal stroke sensor assembly malfunction.

SAE Code C1392:

-

After any of the following situations, if the zero point of the brake pedal stroke sensor 1 or brake pedal stroke sensor 2 has not been learned and the vehicle is being driven at a certain speed or more, the skid control ECU (brake booster with master cylinder assembly) judges that the zero point of the brake pedal stroke sensor is uncalibrated and illuminates the MIL and stores this DTC.

- The skid control ECU (brake booster with master cylinder assembly) has been replaced with a new one.

- After the brake actuator assembly, brake pedal stroke sensor assembly or brake pedal is removed and installed or replaced, the zero point is cleared.

P057C, P057D, P057E, P05DD, P05DE, P05DF and P05E0:

-

The skid control ECU (brake booster with master cylinder assembly) monitors the output value of the brake pedal stroke sensor assembly, and if the following conditions are detected, the skid control ECU (brake booster with master cylinder assembly) judges that the brake pedal stroke sensor assembly has a malfunction and illuminates the MIL and stores a DTC.

-

The power supply voltage ratio of the brake pedal stroke sensor 1 and brake pedal stroke sensor 2 is outside the normal range.

HINT:

The power supply voltage ratio is the ratio of the voltage of SKS1 and VSK1 or SKS2 and VSK2.

- When the brake pedal is operated, the relationship between the value output by the brake pedal stroke sensor 1 and brake pedal stroke sensor 2 is outside the normal range.

-

The difference between the current power supply voltage ratio and the previous power supply voltage ratio of the brake pedal stroke sensor 1 and brake pedal stroke sensor 2 exceeds a specific value (improbable sudden change repeats).

HINT:

The power supply voltage ratio is the ratio of the voltage of SKS1 and VSK1 or SKS2 and VSK2.

-

The power supply voltage ratio of the brake pedal stroke sensor 1 and brake pedal stroke sensor 2 is outside the normal range.

C1392 (INF Code 1124):

-

After any of the following situations, if the zero point of the brake pedal stroke sensor 1 or brake pedal stroke sensor 2 has not been learned, the skid control ECU (brake booster with master cylinder assembly) judges that the zero point of the brake pedal stroke sensor is uncalibrated and illuminates the ABS warning, brake warning / red (malfunction), brake warning / yellow (minor malfunction) and slip indicator lights and stores this DTC.

- The skid control ECU (brake booster with master cylinder assembly) has been replaced with a new one.

-

After the brake actuator assembly, brake pedal stroke sensor assembly or brake pedal is removed and installed or replaced, the zero point is cleared.

HINT:

As the detection conditions slightly differ from SAE code C1392, the detection conditions for DTC C1392 (INF code 1124) is also provided.

MONITOR STRATEGY

HINT:

SAE code only.

|

Related DTCs |

C0562: Brake pedal stroke sensor assembly voltage circuit/open C124B: Brake pedal stroke sensor assembly invalid data C1392: Brake pedal stroke sensor learning not complete P057C: Brake pedal stroke sensor assembly open circuit P057D: Brake pedal stroke sensor assembly circuit high P057E: Brake pedal stroke sensor assembly intermittent/erratic P05DD: Brake pedal stroke sensor assembly open circuit P05DE: Brake pedal stroke sensor assembly circuit high P05DF: Brake pedal stroke sensor assembly intermittent/erratic P05E0: Brake pedal stroke sensor assembly "1"/"2" correlation |

|

Required Sensors/Components(Main) |

Brake pedal stroke sensor assembly Skid control ECU (brake booster with master cylinder assembly) |

|

Required Sensors/Components(Related) |

Skid control ECU (brake booster with master cylinder assembly) Brake pedal stroke sensor assembly Speed sensor |

|

Frequency of Operation |

Continuous |

|

Duration |

-: C1392 0.2 seconds: C0562, C124B, P057C, P057D, P057E, P05DD, P05DE, P05DF and P05E0 |

|

MIL Operation |

Immediately |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

HINT:

SAE code only.

C0562

|

Monitor runs whenever the following DTCs are not stored |

None |

|

Brake system voltage 1 (VM1) |

Higher than 6.92 V |

C124B

|

Monitor runs whenever the following DTCs are not stored |

C0562 (Brake pedal stroke sensor assembly voltage circuit/open) P057C, P05DD (Brake pedal stroke sensor assembly open circuit) P057D, P05DE (Brake pedal stroke sensor assembly circuit high) P057E, P05DF (Brake pedal stroke sensor assembly intermittent/erratic) P05E0 (Brake pedal stroke sensor assembly "1"/"2" correlation) |

|

All of the following conditions are met |

- |

|

Brake system voltage 1 (VM1) |

Higher than 6.92 V |

|

Serial communication with high side IC |

Valid |

|

Brake pedal stroke sensor assembly fail (C0562, P057C, P057D, P057E, P05DD, P05DE, P05DF, P05E0) |

Not detected |

C1392

|

Monitor runs whenever the following DTCs are not stored |

None |

|

Vehicle speed |

40 km/h (25 mph) or more |

P057C, P057D, P057E, P05DD, P05DE and P05DF

|

Monitor runs whenever the following DTCs are not stored |

None |

|

Brake pedal stroke sensor assembly power supply |

4.74 V or more, and 5.23 V or less |

P05E0

|

Monitor runs whenever the following DTCs are not stored |

C0562 (Brake pedal stroke sensor assembly voltage circuit/open) C124B (Brake pedal stroke sensor assembly invalid data) P057C, P05DD (Brake pedal stroke sensor assembly open circuit) P057D, P05DE (Brake pedal stroke sensor assembly circuit high) P057E, P05DF (Brake pedal stroke sensor assembly intermittent/erratic) |

|

Both of the following conditions are met |

- |

|

Brake system voltage 1 (VM1) |

Higher than 6.92 V |

|

Brake pedal stroke sensor assembly fail (C0562, C124B, P057C, P057D, P057E, P05DD, P05DE, P05DF) |

Not detected |

TYPICAL MALFUNCTION THRESHOLDS

HINT:

SAE code only.

C0562

|

Brake pedal stroke sensor assembly power supply |

Less than 4.74 V, or higher than 5.23 V |

C124B

|

Brake pedal stroke sensor assembly state |

Invalid |

C1392

|

Either of the following conditions is met |

- |

|

Brake pedal stroke sensor 1 zero point calibration value |

Not stored |

|

Brake pedal stroke sensor 2 zero point calibration value |

Not stored |

P057C and P05DD

|

Power supply voltage ratio of SKS and VSK |

Less than 0.06 |

HINT:

The power supply voltage ratio is the ratio of the voltage of SKS1 and VSK1 or SKS2 and VSK2.

P057D and P05DE

|

Power supply voltage ratio of SKS and VSK |

Higher than 0.94 |

HINT:

The power supply voltage ratio is the ratio of the voltage of SKS1 and VSK1 or SKS2 and VSK2.

P057E and P05DF

|

Difference between the current power supply voltage ratio and the previous power supply voltage ratio of SKS and VSK |

Higher than 8.5% |

HINT:

The power supply voltage ratio is the ratio of the voltage of SKS1 and VSK1 or SKS2 and VSK2.

P05E0

|

Brake pedal stroke sensor assembly correlation state |

Invalid |

COMPONENT OPERATING RANGE

HINT:

SAE code only.

C0562

|

Both of the following conditions are met |

- |

|

Brake system voltage 1 (VM1) |

Higher than 6.92 V |

|

Brake pedal stroke sensor assembly power supply |

4.74 V or more, and 5.23 V or less |

C124B

|

Both of the following conditions are met |

- |

|

Brake system voltage 1 (VM1) |

Higher than 6.92 V |

|

Brake pedal stroke sensor assembly state |

Valid |

C1392

|

Both of the following conditions are met |

- |

|

Brake pedal stroke sensor 1 zero point calibration value |

Stored |

|

Brake pedal stroke sensor 2 zero point calibration value |

Stored |

P057C, P05DD, P057D and P05DE

|

Both of the following conditions are met |

- |

|

Brake pedal stroke sensor assembly power supply |

4.74 V or more, and 5.23 V or less |

|

Power supply voltage ratio of SKS and VSK |

0.06 or more, and 0.94 or less |

HINT:

The power supply voltage ratio is the ratio of the voltage of SKS1 and VSK1 or SKS2 and VSK2.

P057E and P05DF

|

Both of the following conditions are met |

- |

|

Brake pedal stroke sensor assembly power supply |

4.74 V or more, and 5.23 V or less |

|

Difference between the current power supply voltage ratio and the previous power supply voltage ratio of SKS and VSK |

8.5% or less |

HINT:

The power supply voltage ratio is the ratio of the voltage of SKS1 and VSK1 or SKS2 and VSK2.

P05E0

|

Both of the following conditions are met |

- |

|

Brake system voltage 1 (VM1) |

Higher than 6.92 V |

|

Brake pedal stroke sensor assembly on experience (low/mid/high) |

On |

CONFIRMATION DRIVING PATTERN

- Connect the Techstream to the DLC3.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the power switch off.

- Turn the power switch on (READY).

- Turn the Techstream on.

- Fully depress the brake pedal.

-

Drive the vehicle at a speed of 40 km/h (25 mph) or more for 1 minute.

HINT:

Only DTC C1392 is stored when the vehicle speed reaches 40 km/h (25 mph).

- Enter the following menus: Chassis / ABS/VSC/TRAC / Trouble Codes.

-

Read the DTCs.

HINT:

- If a DTC is output, the system is malfunctioning.

- If a DTC is not output, perform the following procedure.

-

If the DTCs are not output, perform a universal trip and check for permanent DTCs.

HINT:

- If a permanent DTC is output, the system is malfunctioning.

- If no permanent DTCs are output, the system is normal.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

After replacing the skid control ECU (brake booster with master cylinder assembly) or brake pedal stroke sensor assembly, perform linear solenoid valve offset learning, ABS holding solenoid valve learning, yaw rate and acceleration sensor zero point calibration and system information memorization after performing "Reset Memory".

HINT:

Check the condition of each related circuit connector before troubleshooting.

PROCEDURE

|

1. |

CHECK BRAKE PEDAL |

(a) Check that the brake pedal and the brake pedal stroke sensor assembly are properly installed and that the pedal can be depressed normally.

(b) Check and adjust the brake pedal height.

(c) Adjust the brake pedal stroke sensor assembly.

|

|

2. |

CHECK DTC |

(a) Clear the DTCs.

Chassis > ABS/VSC/TRAC > Clear DTCs

(b) Turn the power switch off.

(c) Turn the power switch on (IG).

(d) Check if the same DTC is output.

Chassis > ABS/VSC/TRAC > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC C1247 is output. |

A |

|

DTC C1392 is output. |

B |

| B |

|

|

|

3. |

CHECK FREEZE FRAME DATA |

(a) Check the INF code from the Freeze Frame Data stored when DTC (C1247) was stored.

Chassis > ABS/VSC/TRAC > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

INF code 211 is output. |

A |

|

INF code 212, 213, 214, 215, 216 or 217 is output. |

B |

| B |

|

|

|

4. |

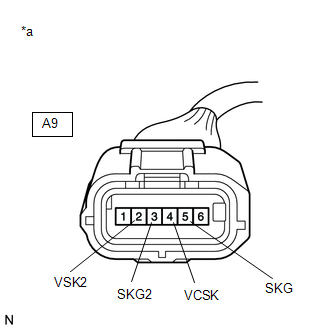

CHECK HARNESS AND CONNECTOR (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY - BRAKE PEDAL STROKE SENSOR ASSEMBLY) |

(a) Turn the power switch off.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(c) Disconnect the A48 skid control ECU (brake booster with master cylinder assembly) connector.

(d) Disconnect the A9 brake pedal stroke sensor assembly connector.

(e) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(f) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A48-13 (SKG1) - A9-5 (SKG) |

Always |

Below 1 Ω |

|

A48-13 (SKG1) or A9-5 (SKG) - Body ground |

Always |

10 kΩ or higher |

|

A48-21 (VSK2) - A9-2 (VSK2) |

Always |

Below 1 Ω |

|

A48-21 (VSK2) or A9-2 (VSK2) - Body ground |

Always |

10 kΩ or higher |

|

A48-25 (VSK1) - A9-4 (VCSK) |

Always |

Below 1 Ω |

|

A48-25 (VSK1) or A9-4 (VCSK) - Body ground |

Always |

10 kΩ or higher |

|

A48-33 (SKG2) - A9-3 (SKG2) |

Always |

Below 1 Ω |

|

A48-33 (SKG2) or A9-3 (SKG2) - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

INSPECT BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY (SENSOR OUTPUT) |

|

(a) Reconnect the A48 skid control ECU (brake booster with master cylinder assembly) connector. |

|

(b) Turn the power switch on (IG).

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A9-4 (VCSK) - A9-5 (SKG) |

Power switch on (IG) |

4.84 to 5.16 V |

|

A9-2 (VSK2) - A9-3 (SKG2) |

Power switch on (IG) |

4.84 to 5.16 V |

| OK |

|

| NG |

|

|

6. |

CHECK HARNESS AND CONNECTOR (BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY - BRAKE PEDAL STROKE SENSOR ASSEMBLY) |

(a) Turn the power switch off.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(c) Disconnect the A48 skid control ECU (brake booster with master cylinder assembly) connector.

(d) Disconnect the A9 brake pedal stroke sensor assembly connector.

(e) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(f) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A48-17 (SKS1) - A9-6 (SKS1) |

Always |

Below 1 Ω |

|

A48-17 (SKS1) or A9-6 (SKS1) - Body ground |

Always |

10 kΩ or higher |

|

A48-19 (SKS2) - A9-1 (SKS2) |

Always |

Below 1 Ω |

|

A48-19 (SKS2) or A9-1 (SKS2) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

7. |

PERFORM BRAKE PEDAL STROKE SENSOR ASSEMBLY ZERO POINT CALIBRATION |

(a) Perform brake pedal stroke sensor assembly zero point calibration.

NOTICE:

Make sure to perform linear solenoid valve offset learning, ABS holding solenoid valve learning, brake pedal stroke sensor assembly zero point calibration and system information memorization after performing "Reset Memory" as the data stored during linear solenoid valve offset learning, ABS holding solenoid valve learning, brake pedal stroke sensor assembly zero point calibration and system information memorization is cleared.

Chassis > ABS/VSC/TRAC > Utility

|

Tester Display |

|---|

|

Reset Memory |

Chassis > ABS/VSC/TRAC > Utility

|

Tester Display |

|---|

|

ECB Utility |

|

|

8. |

RECONFIRM DTC |

(a) Clear the DTCs.

Chassis > ABS/VSC/TRAC > Clear DTCs

(b) Turn the power switch off.

(c) Turn the power switch on (IG).

(d) Check if the same DTC is output.

Chassis > ABS/VSC/TRAC > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC C1392 is output. |

A |

|

DTCs are not output. |

B |

|

DTCs other than C1392 are output. |

C |

| B |

|

END |

| C |

|

|

|

9. |

INSPECT BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY (SENSOR OUTPUT) |

|

(a) Turn the power switch off. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(c) Disconnect the A9 brake pedal stroke sensor assembly connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Turn the power switch on (IG).

(f) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A9-4 (VCSK) - A9-5 (SKG) |

Power switch on (IG) |

4.84 to 5.16 V |

|

A9-2 (VSK2) - A9-3 (SKG2) |

Power switch on (IG) |

4.84 to 5.16 V |

| OK |

|

| NG |

|

|

|

|

![2020 - 2022 MY Corolla Corolla HV [01/2019 - 09/2022]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for HV Model): DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)