- Reset memory

- Deceleration sensor zero point calibration

- CVT oil pressure calibration

| Last Modified: 01-27-2025 | 6.11:8.1.0 | Doc ID: RM100000001G45P |

| Model Year Start: 2020 | Model: Corolla | Prod Date Range: [01/2019 - 03/2019] |

| Title: 2ZR-FAE (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL; 2020 MY Corolla [01/2019 - 03/2019] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during engine unit removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*1: w/ Smart Key System

*2: w/o Smart Key System |

|||

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Control System |

|

|

Pre-collision System |

|||

|

Lighting System (w/ AFS)(EXT) |

|||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

|

|

||

|

Replacement of ECM*1 |

Code registration (Smart Key System (for Gasoline Model, Start Function)) |

|

|

|

Replacement of ECM*2 |

Code registration (Immobiliser system) |

Engine start |

|

|

Inspection After Repair |

|

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Perform headlight ECU sub-assembly LH initialization |

Lighting system (w/ AFS)(EXT) |

|

|

Front wheel alignment adjustment |

|

|

|

|

CVT fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly |

|

NOTICE:

- After the ignition switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the ignition switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Audio and Visual System (for Gasoline Model))

- After the engine switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Navigation System)

PROCEDURE

1. REMOVE THROTTLE BODY ASSEMBLY

2. REMOVE INTAKE MANIFOLD

3. REMOVE PURGE VALVE (PURGE VSV)

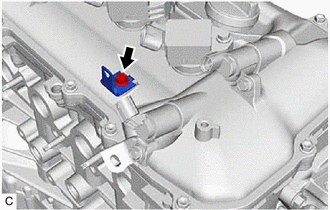

(a) Remove the 2 bolts and purge valve (purge VSV) from the cylinder head cover sub-assembly.

4. DISCONNECT FUEL TUBE SUB-ASSEMBLY

5. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

6. REMOVE NO. 1 DELIVERY PIPE SPACER

7. REMOVE FUEL INJECTOR ASSEMBLY

8. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

(a) Remove the engine oil level dipstick.

|

(b) Remove the bolt and engine oil level dipstick guide. |

|

(c) Remove the O-ring from the engine oil level dipstick guide.

9. REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

10. REMOVE DRIVE SHAFT HEAT INSULATOR SUB-ASSEMBLY

11. REMOVE MANIFOLD STAY

12. REMOVE EXHAUST MANIFOLD

13. REMOVE VENTILATION HOSE

14. DISCONNECT NO. 3 WATER BY-PASS HOSE

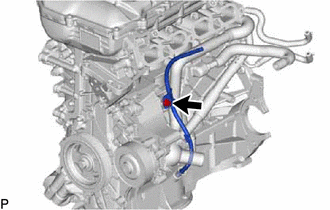

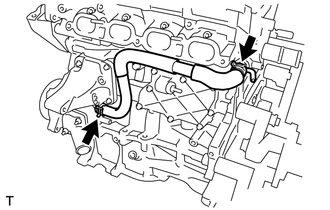

|

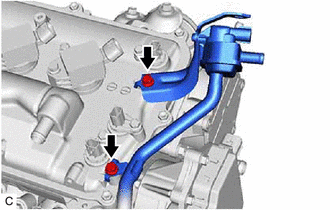

(a) Slide the clip and disconnect the No. 3 water by-pass hose from the water inlet housing |

|

15. REMOVE NO. 1 WATER BY-PASS PIPE

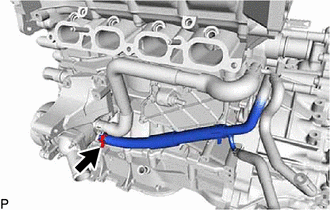

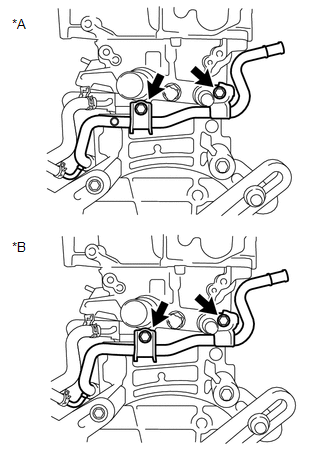

|

(a) Remove the 2 bolts and No. 1 water by-pass pipe. |

|

16. REMOVE WATER BY-PASS HOSE

|

(a) Slide the clip and remove the water by-pass hose from the cylinder head sub-assembly. |

|

17. REMOVE WATER INLET HOSE

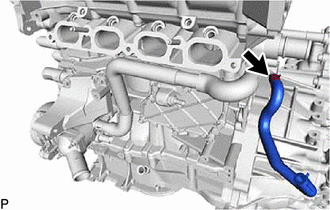

|

(a) Slide the 2 clips and remove the water inlet hose. |

|

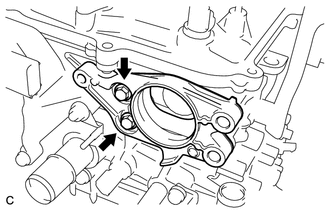

18. SEPARATE WATER INLET

19. REMOVE THERMOSTAT

20. REMOVE VACUUM PUMP ASSEMBLY

21. REMOVE NO. 1 VACUUM PUMP BRACKET

|

(a) Remove the 2 bolts, No. 1 vacuum pump bracket and gasket. |

|

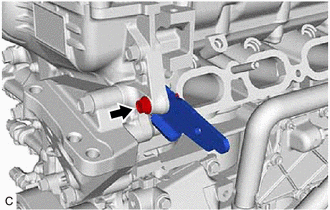

22. REMOVE NO. 2 GENERATOR BRACKET

|

(a) Remove the bolt and No. 2 generator bracket from the cylinder head sub-assembly. |

|

23. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

NOTICE:

Do not supply oil to the tensioner when an abnormal noise of the belt occurs.

|

(a) Remove the 2 bolts and V-ribbed belt tensioner assembly from the engine assembly. |

|

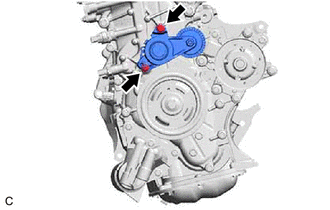

24. REMOVE WIRE HARNESS CLAMP BRACKET

|

(a) Remove the bolt and wire harness clamp bracket from the cylinder head cover sub-assembly. |

|

25. REMOVE IGNITION COIL ASSEMBLY

26. REMOVE ENGINE OIL TEMPERATURE SENSOR

|

|

|

![2019 - 2022 MY Corolla Corolla Hatchback GR Corolla [06/2018 - 09/2022]; PRE-COLLISION: PRE-COLLISION SYSTEM (for Gasoline Model): INITIALIZATION](/t3Portal/stylegraphics/info.gif)