- DTC judgment completed

- System normal

| Last Modified: 05-13-2024 | 6.11:8.1.0 | Doc ID: RM100000001D0X4 |

| Model Year Start: 2019 | Model: Corolla Hatchback | Prod Date Range: [06/2018 - 11/2022] |

| Title: K120 / K121 (CVT): K120 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: P050031; Vehicle Speed Sensor "A" No Signal; 2019 - 2023 MY Corolla Corolla Hatchback [06/2018 - 11/2022] | ||

|

DTC |

P050031 |

Vehicle Speed Sensor "A" No Signal |

DESCRIPTION

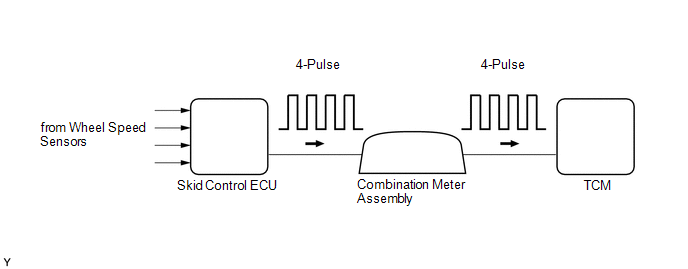

Vehicles which are equipped with ABS (Anti-lock Brake System) detect the vehicle speed using the skid control ECU (brake actuator assembly) and wheel speed sensors. Each wheel speed sensor monitors the wheel rotation speed and sends a signal to the skid control ECU. The skid control ECU converts the wheel speed signals into a 4-pulse signal and transmits it to the TCM via the combination meter assembly. The TCM determines the vehicle speed based on the frequency of the pulse signal.

HINT:

- Various systems use the vehicle speed signal distributed from the combination meter assembly. Check all the components possibly related to the speed signal.

- A voltage of 12 V or 5 V is output from each ECU and then input to the combination meter assembly. The signal is changed to a pulse signal at the transistor in the combination meter assembly. Each ECU controls the respective system based on the pulse signal.

- If a short occurs in any of the ECUs or in the wire harness connected to an ECU, all systems using the speed signal will not operate normally.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

Note |

|---|---|---|---|---|---|---|

|

P050031 |

Vehicle Speed Sensor "A" No Signal |

When the speed indicated by transmission revolution sensor (NOUT) and (NSS) are 380 rpm or more, no vehicle speed sensor signal is received by the TCM for 5 seconds or more (1-trip detection logic). |

|

Comes on |

DTC stored |

SAE Code: P0500 |

MONITOR DESCRIPTION

If no speed signal is received from the combination meter assembly even though the TCM determines that the vehicle is being driven, the TCM interprets this as a malfunction in the speed signal circuit. The TCM then illuminates the MIL and stores this DTC.

MONITOR STRATEGY

|

Related DTCs |

P0500: Vehicle speed sensor/Verify pulse input |

|

Required sensors/Components (Main) |

Vehicle speed sensor, Combination meter assembly, Skid control ECU |

|

Required sensors/Components (Sub) |

Transmission revolution sensor (NOUT) Transmission revolution sensor (NSS) Engine coolant temperature sensor |

|

Frequency of operation |

Continuous |

|

Duration |

5 sec. |

|

MIL operation |

Immediate |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

|

Battery voltage |

8 V or more |

|

Engine switch |

On (IG) |

|

Starter |

OFF |

|

D range position switch |

ON |

|

R range position switch |

OFF |

|

Park position switch |

OFF |

|

Neutral position switch |

OFF |

|

Engine |

Running |

|

Pressure control solenoid circuit fail (P08CA, P08CB, P0962, P0963, P0966, P0967, P2826, P2827, P282F, P2830) (Pending + MIL) |

Not detected |

|

Torque converter clutch pressure control solenoid circuit fail (P2763, P2764) (Pending + MIL) |

Not detected |

|

Output speed sensor revolution |

380 rpm or more |

|

Intermediate shaft speed sensor for belt drive revolution |

380 rpm or more |

|

One of the following conditions is met |

- |

|

- Speed sensor monitor driving mode |

Belt mode (Synchronizer engaged) |

|

- Speed sensor monitor driving mode |

Belt mode (Synchronizer released) |

One of the following conditions is met: Condition (A) or (B)

-

Condition (A)

ECT

20°C (68°F) or higher

ECT sensor circuit fail (P0117, P0118)

(Pending + MIL)

Not detected

All of the following conditions are met:

2 sec. or more

- Park position switch

OFF

- Neutral position switch

OFF

Condition (B)

One of the following conditions is met

-

- ECT

Less than 20°C (68°F)

- ECT sensor circuit fail (P0117, P0118)

(Pending + MIL)

Detected

All of the following conditions are met:

30 sec. or more

- Park position switch

OFF

- Neutral position switch

OFF

TYPICAL MALFUNCTION THRESHOLDS

|

Vehicle speed sensor signal |

No signal |

CONFIRMATION DRIVING PATTERN

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

- Connect the Techstream to the DLC3.

- Turn the engine switch on (IG) and turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the engine switch off and wait for 2 minutes or more.

- Turn the engine switch on (IG) and turn the Techstream on.

- Start the engine.

-

Perform the D Position Shift Test inspection in Road Test. [*1]

HINT:

[*1]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Stop the vehicle.

- Enter the following menus: Powertrain / Transmission / Utility / All Readiness.

- Input the DTC: P050031.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to Speed Signal Circuit.

CAUTION / NOTICE / HINT

CAUTION:

-

Strictly observe posted speed limits, traffic laws and road conditions.

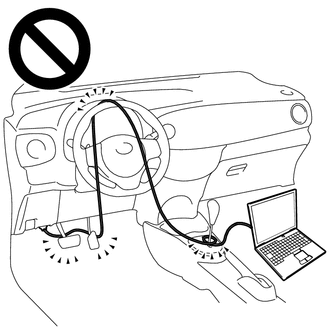

- Do not drive the vehicle with the cable of the Techstream contacting the pedals, shift lever or steering wheel.

- Driving the vehicle with the cable of the Techstream contacting these areas could impede vehicle control, resulting in a serious accident.

-

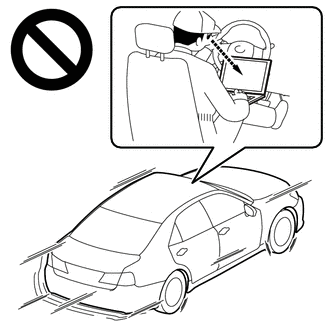

Do not operate the Techstream while driving the vehicle.

- Operating the Techstream while driving the vehicle will prevent you from paying sufficient attention to vehicle surroundings, and could result in a serious accident.

NOTICE:

HINT:

Read freeze frame data using the Techstream. The TCM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

|

1. |

READ VALUE USING TECHSTREAM (VEHICLE SPEED) |

(a) Drive the vehicle and check whether the operation of the speedometer is normal.

HINT:

- The vehicle speed sensor is operating normally if the speedometer reading is normal.

- If the speedometer does not operate, check it by following the diagnostic procedure for a malfunction of the speedometer.

(b) Connect the Techstream to the DLC3.

(c) Turn the engine switch on (IG) and turn the Techstream on.

(d) Enter the following menus: Powertrain / Transmission / Data List / Vehicle Speed.

Powertrain > Transmission > Data List

|

Tester Display |

|---|

|

Vehicle Speed |

(e) Drive the vehicle.

(f) According to the display on the Techstream, read the Data List.

Powertrain > Transmission > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Vehicle Speed |

Vehicle speed |

Min.: 0 km/h (0 mph) Max.: 255 km/h (158 mph) |

Actual vehicle speed |

|

OK:

The values displayed on the Techstream and speedometer are equal.

| OK |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - TCM) |

(a) Disconnect the I4 combination meter assembly connector.

(b) Disconnect the C80 TCM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C80-42 (SPD) - I4-36 (+S) |

Always |

Below 1 Ω |

(d) Connect the C80 TCM connector.

(e) Connect the I4 combination meter assembly connector.

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK METER / GAUGE SYSTEM |

(a) Proceed to Speed Signal Circuit in Meter/Gauge System.

|

|

4. |

CONFIRM MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Clear the DTCs.

Powertrain > Transmission > Clear DTCs

(e) Turn the engine switch off and wait for at least 30 seconds.

(f) Start the engine.

(g) Turn the Techstream on.

(h) Drive the vehicle at 24 km/h (15 mph) or more.

(i) Enter the following menus: Powertrain / Transmission / Trouble Codes.

(j) Read the DTCs.

Powertrain > Transmission > Trouble Codes

HINT:

If no DTCs (including pending DTCs) are output, the repair has been successfully completed.

| NEXT |

|

END |

|

|

|

![2019 - 2022 MY Corolla Corolla Hatchback [06/2018 - 09/2022]; K120 / K121 (CVT): K120 CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)