| Last Modified: 07-31-2024 | 6.11:8.1.0 | Doc ID: RM100000001CY52 |

| Model Year Start: 2019 | Model: GR Corolla | Prod Date Range: [06/2018 - 01/2019] |

| Title: NETWORKING: LIN COMMUNICATION SYSTEM (for Gasoline Model): B2325; LIN Communication Bus Malfunction; 2019 MY Corolla Corolla Hatchback GR Corolla [06/2018 - 01/2019] | ||

|

DTC |

B2325 |

LIN Communication Bus Malfunction |

DESCRIPTION

If the main body ECU (multiplex network body ECU) detects a communication error with an ECU connected to the door bus lines for 8 seconds or more, DTC B2325 will be stored.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

B2325 |

LIN Communication Bus Malfunction |

The main body ECU (multiplex network body ECU) detects a communication error with an ECU connected to the door bus lines for 8 seconds or more. |

|

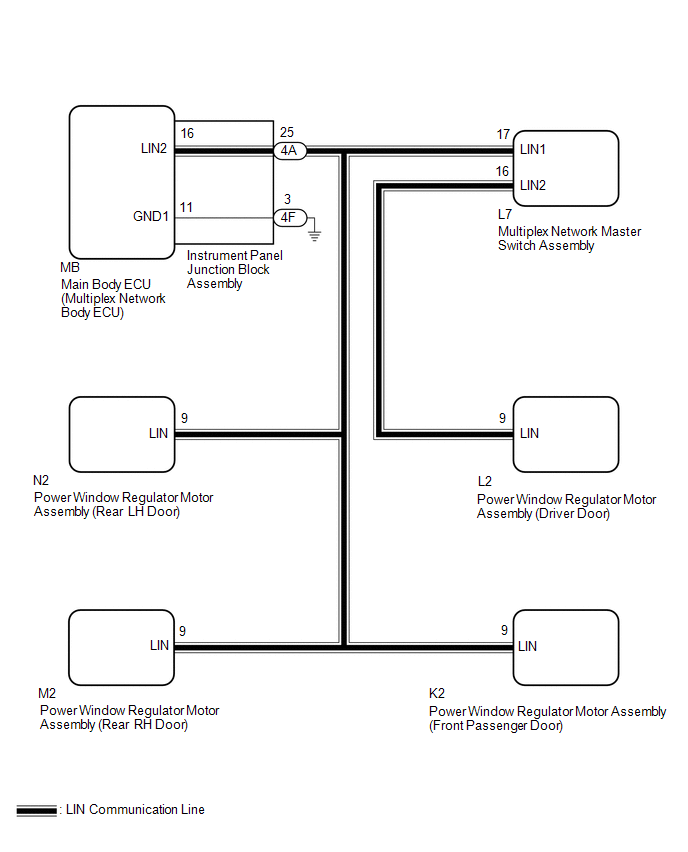

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

PROCEDURE

|

1. |

CHECK POWER WINDOW REGULATOR MOTOR ASSEMBLY (DRIVER DOOR) |

(a) Disconnect the L2 power window regulator motor assembly (driver door) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs

(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC B2325 is output |

A |

|

DTC B2325 is not output |

B |

| B |

|

|

|

2. |

CHECK MULTIPLEX NETWORK MASTER SWITCH ASSEMBLY |

(a) Disconnect the L7 multiplex network master switch assembly connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs

(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC B2325 is output |

A |

|

DTC B2325 is not output |

B |

| B |

|

|

|

3. |

CHECK POWER WINDOW REGULATOR MOTOR ASSEMBLY (FRONT PASSENGER DOOR) |

(a) Disconnect the K2 power window regulator motor assembly (front passenger door) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs

(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC B2325 is output |

A |

|

DTC B2325 is not output |

B |

| B |

|

REPLACE POWER WINDOW REGULATOR MOTOR ASSEMBLY (FRONT PASSENGER DOOR) |

|

|

4. |

CHECK POWER WINDOW REGULATOR MOTOR ASSEMBLY (REAR RH DOOR) |

(a) Disconnect the M2 power window regulator motor assembly (rear RH door) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs

(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC B2325 is output |

A |

|

DTC B2325 is not output |

B |

| B |

|

REPLACE POWER WINDOW REGULATOR MOTOR ASSEMBLY (REAR RH DOOR) |

|

|

5. |

CHECK POWER WINDOW REGULATOR MOTOR ASSEMBLY (REAR LH DOOR) |

(a) Disconnect the N2 power window regulator motor assembly (rear LH door) connector.

(b) Clear the DTCs.

Body Electrical > Main Body > Clear DTCs

(c) After 10 seconds have elapsed, check if the same DTC is output again.

Body Electrical > Main Body > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC B2325 is output |

A |

|

DTC B2325 is not output |

B |

| B |

|

REPLACE POWER WINDOW REGULATOR MOTOR ASSEMBLY (REAR LH DOOR) |

|

|

6. |

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - EACH ECU) |

(a) Disconnect the 4A instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

4A-25 - Body ground |

Always |

10 kΩ or higher |

(c) Disconnect all other connectors in the same circuit.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

4A-25 - Other terminals |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

7. |

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

(a) Remove the instrument panel junction block assembly.

(b) Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

|

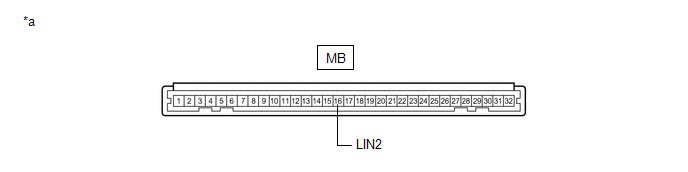

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

(c) Measure the resistance according to the value(s) in the table below.

HINT:

This inspection is to check the LIN communication line in the instrument panel junction block assembly that connects the wire harness to the built-in main body ECU (multiplex network body ECU).

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

MB-16 (LIN2) - Other terminals |

Always |

10 kΩ or higher |

| NG |

|

|

|

8. |

CHECK MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

(a) Install the main body ECU (multiplex network body ECU) to the instrument panel junction block assembly.

(b) Connect all instrument panel junction block assembly connectors other than 4F and 4A.

|

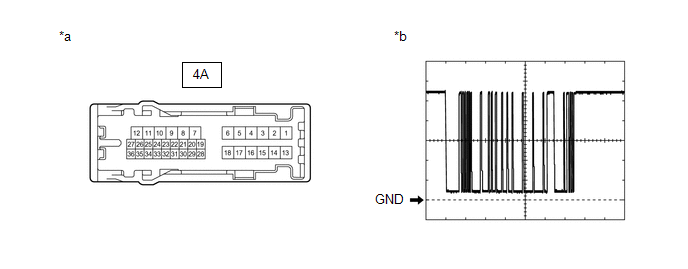

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

*b |

Waveform |

(c) Using a Techstream, check the waveform.

HINT:

This inspection is to check the LIN communication line in the instrument panel junction block assembly that connects the wire harness to the built-in main body ECU (multiplex network body ECU).

OK:

|

Tester Connection |

Condition |

Tool Setting |

Specified Condition |

|---|---|---|---|

|

4A-25 - Body ground |

Engine switch on (IG) |

2 V/DIV., 200 ms/DIV. |

Pulse generation (See waveform) |

| OK |

|

| NG |

|

|

9. |

CHECK HARNESS AND CONNECTOR (MULTIPLEX NETWORK MASTER SWITCH ASSEMBLY - POWER WINDOW REGULATOR MOTOR ASSEMBLY (DRIVER DOOR)) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

L7-16 (LIN2) - Body ground |

Always |

10 kΩ or higher |

|

L7-16 (LIN2) - Other terminals |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2019 - 2022 MY Corolla Corolla Hatchback GR Corolla [06/2018 - 09/2022]; WINDOW / GLASS: POWER WINDOW CONTROL SYSTEM (for Gasoline Model): INITIALIZATION](/t3Portal/stylegraphics/info.gif)