| Last Modified: 08-22-2025 | 6.11:8.1.0 | Doc ID: RM0000003TPCPDA |

| Model Year Start: 2019 | Model: Corolla Hatchback | Prod Date Range: [06/2018 - 01/2019] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model with Electric Parking Brake System): C052F14; ABS Pump Motor Supply Voltage Circuit Short to Ground or Open; 2019 MY Corolla Corolla Hatchback [06/2018 - 01/2019] | ||

|

DTC |

C052F14 |

ABS Pump Motor Supply Voltage Circuit Short to Ground or Open |

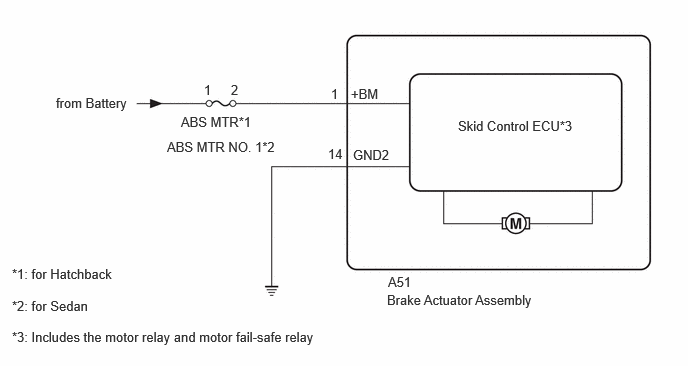

DESCRIPTION

The ABS motor relay is built into the brake actuator assembly.

When the skid control ECU (brake actuator assembly) operates ABS, TRAC, VSC, brake hold or brake assist, the ABS motor relay turns ON and drives the motor pump built into the brake actuator assembly.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

C052F14 |

ABS Pump Motor Supply Voltage Circuit Short to Ground or Open |

Any of the following conditions are met:

|

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

- Before performing troubleshooting, make sure to confirm that the battery voltage is normal.

- After replacing the skid control ECU (brake actuator assembly), perform acceleration sensor zero point calibration and store system information memorization.

PROCEDURE

|

1. |

CHECK FREEZE FRAME DATA (MOTOR POWER SUPPLY VOLTAGE) |

(a) Select a DTC to display the Freeze Frame Data.

(b) Read the freeze frame data of DTC C052F14.

Chassis > Brake

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Motor Power Supply Voltage |

+BM terminal voltage value (value detected by ECU) |

Min.: 0.0 V, Max.: 25.5 V |

Ignition switch ON: 11.0 to 14.0 V |

Changes in proportion to battery voltage HINT: This is the voltage detected at terminal +BM (which supplies power to the ABS motor) of the skid control ECU (brake actuator assembly) |

Chassis > Brake > DTC(C052F14) > Freeze Frame Data

|

Tester Display |

|---|

|

Motor Power Supply Voltage |

|

Result |

Proceed to |

|---|---|

|

The value of Motor Power Supply Voltage is less than 1.5 V. |

A |

|

The value of Motor Power Supply Voltage is 1.5 V or more. |

B |

| B |

|

|

|

2. |

CHECK VEHICLE CONDITION (CHECK FOR AFTERMARKET PARTS) |

(a) Consult with the customer to determine whether any aftermarket electrical components are currently installed to the vehicle, or had ever been installed to the vehicle in the past.

|

Result |

Proceed to |

|---|---|

|

No aftermarket electrical components. (for Hatchback) |

A |

|

No aftermarket electrical components. (for Sedan) |

B |

|

Aftermarket electrical components are/were installed. |

C |

| B |

|

| C |

|

EFFECT OF AFTERMARKET PARTS |

|

|

3. |

CHECK HARNESS AND CONNECTOR (ABS MTR FUSE - +BM TERMINAL) |

(a) Remove the ABS MTR fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(c) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

2 (ABS MTR fuse holder) - A51-1 (+BM) |

Ignition switch off |

Below 1 Ω |

|

2 (ABS MTR fuse holder) and A51-1 (+BM) - Body ground |

Ignition switch off |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

4. |

CHECK HARNESS AND CONNECTOR (ABS MTR NO. 1 FUSE - +BM TERMINAL) |

(a) Remove the ABS MTR NO. 1 fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(c) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

2 (ABS MTR NO. 1 fuse holder) - A51-1 (+BM) |

Ignition switch off |

Below 1 Ω |

|

2 (ABS MTR NO. 1 fuse holder) and A51-1 (+BM) - Body ground |

Ignition switch off |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

CHECK HARNESS AND CONNECTOR (+BM TERMINAL) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

A51-1 (+BM) - Body ground |

Ignition switch off |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CHECK HARNESS AND CONNECTOR (GND2 TERMINAL) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A51-13 (GND2) - Body ground |

1 minute or more after disconnecting the cable from the negative (-) battery terminal |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

7. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Brake > Clear DTCs

(b) Turn the ignition switch off.

|

|

8. |

RECONFIRM DTC |

(a) Based on the Freeze Frame Data and interview with the customer, attempt to reproduce the conditions when the malfunction occurred.

(b) Check if the same DTC is output.

Chassis > Brake > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

C052F14 is not output |

A |

|

C052F14 is output |

B |

| A |

|

| B |

|

|

9. |

CHECK FREEZE FRAME DATA (MOTOR POWER SUPPLY VOLTAGE) |

(a) Select a DTC to display the Freeze Frame Data.

(b) Read the freeze frame data of DTC C052F14.

Chassis > Brake

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Motor Power Supply Voltage |

+BM terminal voltage value (value detected by ECU) |

Min.: 0.0 V, Max.: 25.5 V |

Ignition switch ON: 11.0 to 14.0 V |

Changes in proportion to battery voltage HINT: This is the voltage detected at terminal +BM (which supplies power to the ABS motor) of the skid control ECU (brake actuator assembly) |

Chassis > Brake > DTC(C052F14) > Freeze Frame Data

|

Tester Display |

|---|

|

Motor Power Supply Voltage |

HINT:

If the +BM terminal voltage is higher than 25.5 V, the display will still show 25.5 V.

|

Result |

Proceed to |

|---|---|

|

The value of Motor Power Supply Voltage is 25.5 V or more. |

A |

|

The value of Motor Power Supply Voltage is less than 25.5 V. |

B |

| B |

|

|

|

10. |

CHECK FREEZE FRAME DATA (BS1 VOLTAGE VALUE) |

(a) Select a DTC to display the Freeze Frame Data.

(b) Read the freeze frame data of DTC C052F14.

Chassis > Brake

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

BS1 Voltage Value |

+BS terminal voltage value (value detected by ECU) |

Min.: 0.0 V, Max.: 25.5 V |

Ignition switch ON: 11.0 to 14.0 V |

Changes in proportion to battery voltage HINT: This is the voltage detected at terminal +BS (which supplies power to each solenoid) of the skid control ECU (brake actuator assembly) |

Chassis > Brake > DTC(C052F14) > Freeze Frame Data

|

Tester Display |

|---|

|

BS1 Voltage Value |

HINT:

If the +BS terminal voltage is higher than 25.5 V, the display will still show 25.5 V.

|

Result |

Proceed to |

|---|---|

|

The value of BS1 Voltage Value is less than 25.5 V. |

A |

|

The value of BS1 Voltage Value is 25.5 V or more. |

B |

| B |

|

|

|

11. |

CHECK VEHICLE CONDITION (CHECK FOR AFTERMARKET PARTS) |

(a) Consult with the customer to determine whether any aftermarket electrical components are currently installed to the vehicle, or had ever been installed to the vehicle in the past.

|

Result |

Proceed to |

|---|---|

|

No aftermarket electrical components. (for Hatchback) |

A |

|

No aftermarket electrical components. (for Sedan) |

B |

|

Aftermarket electrical components are/were installed. |

C |

| B |

|

| C |

|

EFFECT OF AFTERMARKET PARTS |

|

|

12. |

CHECK HARNESS AND CONNECTOR (ABS MTR FUSE - +BM TERMINAL) |

(a) Remove the ABS MTR fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(c) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

2 (ABS MTR fuse holder) - A51-1 (+BM) |

Ignition switch off |

Below 1 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

13. |

CHECK HARNESS AND CONNECTOR (ABS MTR NO. 1 FUSE - +BM TERMINAL) |

(a) Remove the ABS MTR NO. 1 fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(c) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

2 (ABS MTR NO. 1 fuse holder) - A51-1 (+BM) |

Ignition switch off |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

14. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Brake > Clear DTCs

(b) Turn the ignition switch off.

|

|

15. |

RECONFIRM DTC |

(a) Based on the Freeze Frame Data and interview with the customer, attempt to reproduce the conditions when the malfunction occurred.

(b) Check if the same DTC is output.

Chassis > Brake > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

C052F14 is not output |

A |

|

C052F14 is output |

B |

| A |

|

| B |

|

|

|

|

![2019 - 2026 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2018 - ]; INTRODUCTION: HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS: HOW TO PROCEED WITH TROUBLESHOOTING](/t3Portal/stylegraphics/info.gif)