| Last Modified: 08-22-2025 | 6.11:8.1.0 | Doc ID: RM0000003TPCPBQ |

| Model Year Start: 2023 | Model: GR Corolla | Prod Date Range: [11/2022 - 08/2023] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model with Electric Parking Brake System): C117A49; Brake System Control Module "A" System Voltage Line Internal Electronic Failure; 2023 MY Corolla Corolla Hatchback GR Corolla [11/2022 - 08/2023] | ||

|

DTC |

C117A49 |

Brake System Control Module "A" System Voltage Line Internal Electronic Failure |

DESCRIPTION

If a malfunction is detected in the power supply circuit, the skid control ECU (brake actuator assembly) stores this DTC and the fail-safe function prohibits ABS operation.

This DTC is stored when the +BS terminal voltage meets one of the DTC detection conditions due to a malfunction in the power supply or charging circuit such as the battery or alternator circuit, etc.

The DTC is cleared when the +BS terminal voltage returns to normal.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

C117A49 |

Brake System Control Module "A" System Voltage Line Internal Electronic Failure |

The vehicle speed is 15 km/h (9 mph) or more and the +BS terminal voltage is 9.6 V or more, the skid control ECU (brake actuator assembly) turns on more than one valve at the same time within a short period of time and the valve relay supply voltage drop exceeds the threshold.* |

|

*: The skid control ECU (brake actuator assembly) monitors the resistance of the power source line at the +BS terminal. A malfunction is detected when an abnormality occurs in the +BS terminal wire harness or its connection and the skid control ECU (brake actuator assembly) determines that the wiring resistance at the +BS terminal exceeds the standard resistance.

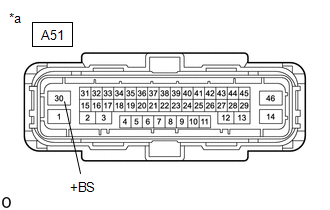

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

PROCEDURE

|

1. |

CHECK VEHICLE CONDITION (CHECK FOR AFTERMARKET PARTS) |

(a) Consult with the customer to determine whether any aftermarket electrical components are currently installed to the vehicle, or had ever been installed to the vehicle in the past.

|

Result |

Proceed to |

|---|---|

|

No aftermarket electrical components. |

A |

|

Aftermarket electrical components are/were installed. |

B |

| B |

|

EFFECT OF AFTERMARKET PARTS |

|

|

2. |

CHECK HARNESS AND CONNECTOR (ABS NO. 2 FUSE - +BS TERMINAL) |

(a) Remove the ABS No. 2 fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(c) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2 (ABS NO. 2 fuse holder) - A51-30 (+BS) |

Ignition switch off |

Below 1 Ω |

|

2 (ABS NO. 2 fuse holder) and A51-30 (+BS) - Body ground |

Ignition switch off |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

CHECK HARNESS AND CONNECTOR (+BS TERMINAL) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A51-30 (+BS) - Body ground |

Ignition switch off |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK HARNESS AND CONNECTOR (GND1 TERMINAL) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A51-46 (GND1) - Body ground |

1 minute or more after disconnecting the cable from the negative (-) battery terminal |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Brake > Clear DTCs

(b) Turn the ignition switch off.

|

|

6. |

RECONFIRM DTC |

(a) Based on the Freeze Frame Data and interview with the customer, attempt to reproduce the conditions when the malfunction occurred.

(b) Check if the same DTC is output.

Chassis > Brake > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

C117A49 is not output |

A |

|

C117A49 is output |

B |

| A |

|

| B |

|

|

|

|

![2019 - 2026 MY Corolla Corolla Hatchback Corolla HV GR Corolla [06/2018 - ]; INTRODUCTION: HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS: HOW TO PROCEED WITH TROUBLESHOOTING](/t3Portal/stylegraphics/info.gif)