| Last Modified: 08-22-2025 | 6.11:8.1.0 | Doc ID: RM0000003TPCMKB |

| Model Year Start: 2023 | Model: Corolla | Prod Date Range: [09/2022 - ] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for HV Model): C052F14; ABS Pump Motor Supply Voltage Circuit Short to Ground or Open; 2023 - 2026 MY Corolla Corolla HV [09/2022 - ] | ||

|

DTC |

C052F14 |

ABS Pump Motor Supply Voltage Circuit Short to Ground or Open |

DESCRIPTION

Refer to DTC C052C11.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

DTC Output from |

Note |

|---|---|---|---|---|---|---|

|

C052F14 |

ABS Pump Motor Supply Voltage Circuit Short to Ground or Open |

Either of the following conditions are met:

|

|

Comes on |

Brake/EPB |

|

MONITOR DESCRIPTION

C055B (Case 1, 2, 4 and 5):

- The skid control ECU (brake actuator assembly) monitors the voltage of the ABS motor relay. If the voltage applied to the relay is a certain value or more or a certain value or less for a certain amount of time, the skid control ECU (brake actuator assembly) illuminates the MIL and stores this DTC.

C055B (Case 3):

- The skid control ECU (brake actuator assembly) has a self-diagnosis function that monitors the pump motor circuit. Under certain conditions, if the pump motor or motor relay self-diagnosis fails a certain number of times for a certain amount of time, the skid control ECU (brake actuator assembly) illuminates the MIL and stores this DTC.

MONITOR STRATEGY

|

Related DTCs |

C055B (Case 1): Pump motor run monitoring C055B (Case 2): Motor relay drain supply monitoring C055B (Case 3): Pump motor test timeout monitoring C055B (Case 4): Motor relay supply voltage line monitoring (out of range high) C055B (Case 5): Motor relay supply voltage line monitoring (out of range low) |

|

Required Sensors/Components(Main) |

Skid control ECU (brake actuator assembly) |

|

Required Sensors/Components(Related) |

Skid control ECU (brake actuator assembly) Speed sensor |

|

Frequency of Operation |

During initial checking |

|

Duration |

0.10 seconds: C055B (Case 4 and 5) 0.15 seconds: C055B (Case 2) 0.48 seconds: C055B (Case 1) 60 seconds: C055B (Case 3) |

|

MIL Operation |

Immediately |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Monitor runs whenever the following DTCs are not stored |

TMC's intellectual property |

|

Other conditions belong to TMC's intellectual property |

- |

TYPICAL MALFUNCTION THRESHOLDS

|

TMC's intellectual property |

- |

COMPONENT OPERATING RANGE

|

TMC's intellectual property |

- |

CONFIRMATION DRIVING PATTERN

NOTICE:

When performing the normal judgment procedure, make sure that the driver door is closed and is not opened at any time during the procedure.

HINT:

- After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off.

- Turn the ignition switch to ON (READY) and turn the GTS on.

- Depress the brake pedal several times to operate the pump motor of the brake actuator assembly. [*1]

-

After the pump motor stops, wait for 2 seconds or more. [*2]

HINT:

[*1] to [*2]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

-

Enter the following menus: Chassis / Brake/EPB* / Utility / All Readiness.

*: Electric Parking Brake System

-

Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE, perform driving pattern again.

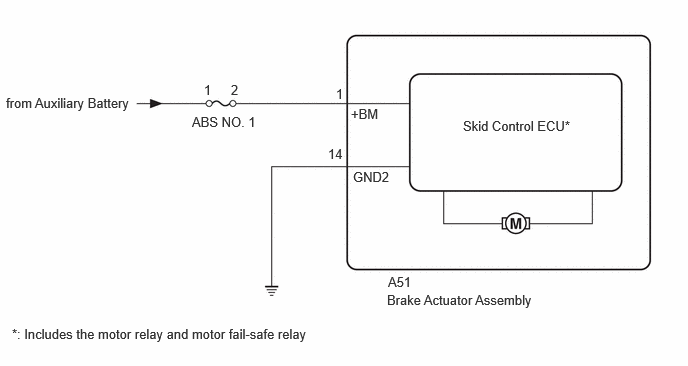

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

PROCEDURE

|

1. |

CHECK FREEZE FRAME DATA (+BM VOLTAGE) |

(a) Select a DTC to display the Freeze Frame Data.

(b) Read the freeze frame data of DTC C052F14.

Chassis > Brake/EPB

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

+BM Voltage |

+BM voltage value (value detected by ECU) |

Min.: 0.0 V, Max.: 25.5 V |

Ignition switch ON: 11.0 to 14.0 V |

Changes in proportion to auxiliary battery voltage HINT: This is the voltage detected at terminal +BM (which supplies power to the ABS motor) of the skid control ECU (brake actuator assembly) |

Chassis > Brake/EPB > DTC(C052F14) > Freeze Frame Data

|

Tester Display |

|---|

|

+BM Voltage |

|

Result |

Proceed to |

|---|---|

|

The value of +BM Voltage is less than 1.5 V. |

A |

|

The value of +BM Voltage is 1.5 V or more. |

B |

| B |

|

|

|

2. |

CHECK VEHICLE CONDITION (CHECK FOR AFTERMARKET PARTS) |

(a) Consult with the customer to determine whether any aftermarket electrical components are currently installed to the vehicle, or had ever been installed to the vehicle in the past.

|

Result |

Proceed to |

|---|---|

|

No aftermarket electrical components. |

A |

|

Aftermarket electrical components are/were installed. |

B |

| B |

|

EFFECT OF AFTERMARKET PARTS |

|

|

3. |

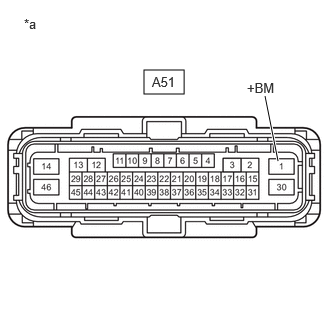

CHECK HARNESS AND CONNECTOR (ABS NO. 1 FUSE - +BM TERMINAL) |

(a) Remove the ABS No. 1 fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(c) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2 (ABS NO. 1 fuse holder) - A51-1 (+BM) |

Ignition switch off |

Below 1 Ω |

|

2 (ABS NO. 1 fuse holder) and A51-1 (+BM) - Body ground |

Ignition switch off |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK HARNESS AND CONNECTOR (+BM TERMINAL) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A51-1 (+BM) - Body ground |

Ignition switch off |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

CHECK HARNESS AND CONNECTOR (GND2 TERMINAL) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(b) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A51-14 (GND2) - Body ground |

1 minute or more after disconnecting the cable from the negative (-) auxiliary battery terminal |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Brake/EPB > Clear DTCs

(b) Turn the ignition switch off.

|

|

7. |

RECONFIRM DTC |

(a) Based on the Freeze Frame Data and interview with the customer, attempt to reproduce the conditions when the malfunction occurred.

(b) Check if the same DTC is output.

Chassis > Brake/EPB > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

C052F14 is not output. |

A |

|

C052F14 is output. |

B |

| A |

|

| B |

|

|

8. |

CHECK FREEZE FRAME DATA (+BM VOLTAGE) |

(a) Select a DTC to display the Freeze Frame Data.

(b) Read the freeze frame data of DTC C052F14.

Chassis > Brake/EPB

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

+BM Voltage |

+BM voltage value (value detected by ECU) |

Min.: 0.0 V, Max.: 25.5 V |

Ignition switch ON: 11.0 to 14.0 V |

Changes in proportion to auxiliary battery voltage HINT: This is the voltage detected at terminal +BM (which supplies power to the ABS motor) of the skid control ECU (brake actuator assembly) |

Chassis > Brake/EPB > DTC(C052F14) > Freeze Frame Data

|

Tester Display |

|---|

|

+BM Voltage |

HINT:

If the +BM terminal voltage is higher than 25.5 V, the display will still show 25.5 V.

|

Result |

Proceed to |

|---|---|

|

The value of +BM Voltage is 25.5 V or more. |

A |

|

The value of +BM Voltage is less than 25.5 V. |

B |

| B |

|

|

|

9. |

CHECK FREEZE FRAME DATA (+BS VOLTAGE) |

(a) Select a DTC to display the Freeze Frame Data.

(b) Read the freeze frame data of DTC C052F14.

Chassis > Brake/EPB

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

+BS Voltage |

+BS voltage value (value detected by ECU) |

Min.: 0.0 V, Max.: 25.5 V |

Ignition switch ON: 11.0 to 14.0 V |

Changes in proportion to auxiliary battery voltage HINT: This is the voltage detected at terminal +BS (which supplies power to each solenoid) of the skid control ECU (brake actuator assembly) |

Chassis > Brake/EPB > DTC(C052F14) > Freeze Frame Data

|

Tester Display |

|---|

|

+BS Voltage |

HINT:

If the +BS terminal voltage is higher than 25.5 V, the display will still show 25.5 V.

|

Result |

Proceed to |

|---|---|

|

The value of +BS Voltage is less than 25.5 V. |

A |

|

The value of +BS Voltage is 25.5 V or more. |

B |

| B |

|

CHECK OR REPLACE CHARGING SYSTEM COMPONENT OR AUXILIARY BATTERY |

|

|

10. |

CHECK VEHICLE CONDITION (CHECK FOR AFTERMARKET PARTS) |

(a) Consult with the customer to determine whether any aftermarket electrical components are currently installed to the vehicle, or had ever been installed to the vehicle in the past.

|

Result |

Proceed to |

|---|---|

|

No aftermarket electrical components. |

A |

|

Aftermarket electrical components are/were installed. |

B |

| B |

|

EFFECT OF AFTERMARKET PARTS |

|

|

11. |

CHECK HARNESS AND CONNECTOR (ABS NO. 1 FUSE - +BM TERMINAL) |

(a) Remove the ABS No. 1 fuse from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Make sure that there is no looseness at the locking part and the connecting part of the connector.

OK:

The connector is securely connected.

(c) Disconnect the A51 skid control ECU (brake actuator assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

2 (ABS NO. 1 fuse holder) - A51-1 (+BM) |

Ignition switch off |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

12. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Brake/EPB > Clear DTCs

(b) Turn the ignition switch off.

|

|

13. |

RECONFIRM DTC |

(a) Based on the Freeze Frame Data and interview with the customer, attempt to reproduce the conditions when the malfunction occurred.

(b) Check if the same DTC is output.

Chassis > Brake/EPB > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

C052F14 is not output. |

A |

|

C052F14 is output. |

B |

| A |

|

| B |

|

|

|

|

![2023 - 2026 MY Corolla Corolla HV [09/2022 - ]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for HV Model): C052C11,C052C13,C142719; ABS Pump Motor Control Circuit Short to Ground](/t3Portal/stylegraphics/info.gif)