- Gas leak from exhaust system is repaired

- Replacement of air fuel ratio sensor

| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM1000000026TKW |

| Model Year Start: 2023 | Model: RAV4 HV | Prod Date Range: [10/2022 - 10/2023] |

| Title: A25A-FXS (ENGINE MECHANICAL): REAR CRANKSHAFT OIL SEAL: REMOVAL; 2023 MY RAV4 HV [10/2022 - 10/2023] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear crankshaft oil seal removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream. | |||

|

Auxiliary battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane control system |

|

|

Parking support brake system (for HV model)* |

|||

|

Pre-collision system |

|||

|

Reset back door close position |

Power back door system (for HV model) |

||

|

Back door lock initialization |

Power door lock control system |

||

|

Replacement of ECM |

Perform Vehicle Identification Number (VIN) registration |

DTC P063051 is output |

|

|

Grille shutter switch specification infomation |

Vehicle control history (RoB) [X260E] is stored |

||

|

|

Inspection after repair |

|

|

|

Replacement of inverter with converter assembly |

Resolver learning |

|

|

|

Replacement of hybrid vehicle transaxle assembly |

|

||

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Parking assist ECU initialization |

Panoramic view monitor system (for HV model) |

||

|

Front wheel alignment adjustment |

|

|

|

|

Front bumper assembly (Including removal and installation) |

Front television camera view adjustment |

Panoramic view monitor system (for HV model) |

|

NOTICE:

- After the ignition switch is turned off, the audio and visual system records various types of memory and settings. As a result, after turning the ignition switch off, make sure to wait at least 2 minutes before disconnecting the cable from the negative (-) auxiliary battery terminal.

- When the cable is disconnected from the negative (-) auxiliary battery terminal and the security lock setting has been enabled, multi-display operations will be disabled upon next startup unless the password is entered. Be sure to check the security lock setting before disconnecting the cable from the negative (-) auxiliary battery terminal.

- This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

PROCEDURE

1. REMOVE HYBRID VEHICLE TRANSAXLE ASSEMBLY

2. REMOVE TRANSMISSION INPUT DAMPER ASSEMBLY

(a) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly horizontal.

- To prevent the No. 2 oil pan sub-assembly from deforming, do not place any attachments under the No. 2 oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

|

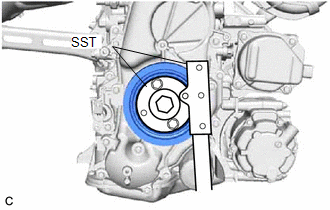

(b) Using SST, hold the crankshaft pulley assembly. SST: 09213-54015 SST: 09330-00021 |

|

|

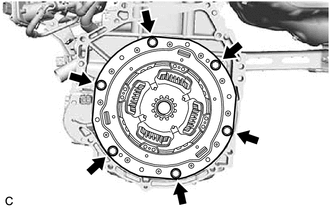

(c) Remove the 6 bolts and transmission input damper assembly from the flywheel sub-assembly. |

|

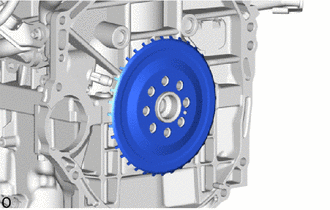

3. REMOVE FLYWHEEL SUB-ASSEMBLY

|

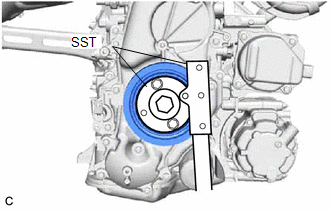

(a) Using SST, hold the crankshaft pulley assembly. SST: 09213-54015 SST: 09330-00021 |

|

|

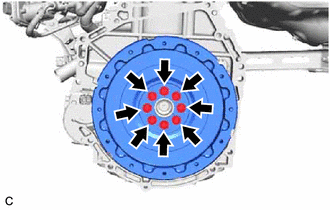

(b) Remove the 8 bolts and flywheel sub-assembly from the crankshaft. |

|

4. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

|

(a) Remove the No. 1 crankshaft position sensor plate. |

|

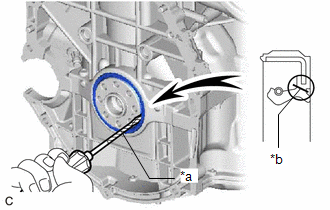

5. REMOVE REAR ENGINE OIL SEAL

|

(a) Using a knife, cut off the lip of the rear engine oil seal. |

|

(b) Using a screwdriver, pry out the rear engine oil seal.

NOTICE:

Be careful not to damage the crankshaft.

HINT:

Tape the screwdriver tip before use.

|

|

|

![2023 MY RAV4 HV [10/2022 - 10/2023]; PARK ASSIST / MONITORING: PARKING SUPPORT BRAKE SYSTEM (for HV Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)