| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM10000000218QL |

| Model Year Start: 2022 | Model: RAV4 | Prod Date Range: [12/2021 - ] |

| Title: PARKING BRAKE: ELECTRIC PARKING BRAKE SYSTEM (w/o Vacuum Brake Booster): C060962; Electric Parking Brake Switch Signal Compare Failure; 2022 - 2024 MY RAV4 RAV4 HV [12/2021 - ] | ||

|

DTC |

C060962 |

Electric Parking Brake Switch Signal Compare Failure |

DESCRIPTION

When the electric parking brake switch (integration control and panel assembly) is pulled, a lock request signal is sent from the No. 2 skid control ECU (brake actuator assembly) to the parking brake actuator assembly. When the electric parking brake switch (integration control and panel assembly) is pushed, a release request signal is sent from the No. 2 skid control ECU (brake actuator assembly) to the parking brake actuator assembly.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Memory |

Note |

|---|---|---|---|---|---|

|

C060962 |

Electric Parking Brake Switch Signal Compare Failure |

|

|

DTC stored |

An electric parking brake system malfunction is displayed on the multi-information display. |

DTC Detection Conditions

|

Vehicle Condition |

|||||||

|---|---|---|---|---|---|---|---|

|

Pattern 1 |

Pattern 2 |

Pattern 3 |

Pattern 4 |

Pattern 5 |

Pattern 6 |

||

|

Diagnosis Condition |

Vehicle is stopped |

- |

- |

○ |

- |

- |

- |

|

Vehicle is being driven |

- |

- |

- |

○ |

- |

- |

|

|

During initial check |

- |

- |

- |

- |

○ |

- |

|

|

Parking brake switch is being operated |

- |

- |

- |

- |

- |

○ |

|

|

Malfunction Status |

Open detected in parking brake switch circuit |

○ |

- |

- |

- |

- |

- |

|

Short detected in parking brake switch circuit |

- |

○ |

- |

- |

- |

- |

|

|

Stuck parking brake switch detected |

- |

- |

○ |

○ |

○ |

○ |

|

|

Detection Time |

1 second or more |

1 second or more |

30 seconds or more |

1 second or more |

1 second or more |

- |

|

|

Number of Trips |

1 trip |

1 trip |

1 trip |

1 trip |

1 trip |

3 trip |

|

HINT:

DTC will be output when conditions for either of the patterns in the table above are met.

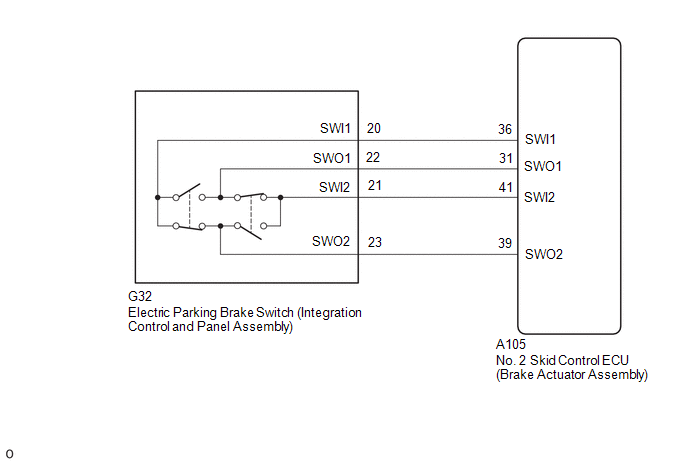

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- When the electric parking brake switch (integration control and panel assembly) is pulled and held for 1 second or more without being pulled fully to the lock side, both of the 2 linked contacts may turn OFF causing this DTC to be stored (this is not a system malfunction).

- To ensure that the electric parking brake does not operate, wait for 3 minutes or more with the ignition switch off, the driver door closed, and the brake pedal not depressed, then disconnect each connector, fuse and relay.

- After replacing the No. 2 skid control ECU (brake actuator assembly), perform "Calibration".

- When replacing the No. 2 skid control ECU (brake actuator assembly), operate the electric parking brake switch (integration control and panel assembly) as the parking brake indicator light blinks when the ignition switch is first turned ON.

PROCEDURE

|

1. |

READ VALUE USING GTS (EPB SWITCH) |

(a) Operate the electric parking brake switch (integration control and panel assembly) and check that the value of "EPB Switch" in the Data List changes between Apply and Release in accordance with the operation of the switch.

Chassis > Brake/EPB > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

EPB Switch |

Electric parking brake switch (integration control and panel assembly) input |

Neutral / Apply / Release / Unknown |

Neutral: Lock switch and release switch are off Apply: Lock switch on Release: Release switch on |

When not normal, electric parking brake switch (integration control and panel assembly) release side system may be malfunctioning HINT: EPB stands for electric parking brake. |

Chassis > Brake/EPB > Data List

|

Tester Display |

|---|

|

EPB Switch |

OK:

The value of EPB Switch changes between Apply and Release in accordance with switch operation.

| NG |

|

|

|

2. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Brake/EPB > Clear DTCs

(b) Turn the ignition switch off.

|

|

3. |

CHECK DTC |

(a) Check for DTCs.

Chassis > Brake/EPB > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs are output |

A |

|

DTCs are not output |

B |

| A |

|

| B |

|

|

4. |

INSPECT ELECTRIC PARKING BRAKE SWITCH (INTEGRATION CONTROL AND PANEL ASSEMBLY) |

| NG |

|

REPLACE ELECTRIC PARKING BRAKE SWITCH (INTEGRATION CONTROL AND PANEL ASSEMBLY) |

|

|

5. |

CHECK HARNESS AND CONNECTOR (NO. 2 SKID CONTROL ECU (BRAKE ACTUATOR ASSEMBLY) - ELECTRIC PARKING BRAKE SWITCH (INTEGRATION CONTROL AND PANEL ASSEMBLY) |

(a) Disconnect the G32 electric parking brake switch (integration control and panel assembly) connector.

(b) Disconnect the A105 No. 2 skid control ECU (brake actuator assembly) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A105-36 (SWI1) - G32-20 (SWI1) |

Always |

Below 1 Ω |

|

A105-31 (SWO1) - G32-22 (SWO1) |

Always |

Below 1 Ω |

|

A105-41 (SWI2) - G32-21 (SWI2) |

Always |

Below 1 Ω |

|

A105-39 (SWO2) - G32-23 (SWO2) |

Always |

Below 1 Ω |

|

A105-36 (SWI1) or G32-20 (SWI1) - Body ground |

Always |

10 kΩ or higher |

|

A105-31 (SWO1) or G32-22 (SWO1) - Body ground |

Always |

10 kΩ or higher |

|

A105-41 (SWI2) or G32-21 (SWI2) - Body ground |

Always |

10 kΩ or higher |

|

A105-39 (SWO2) or G32-23 (SWO2) - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CLEAR DTC |

(a) Clear the DTCs.

Chassis > Brake/EPB > Clear DTCs

(b) Turn the ignition switch off.

|

|

7. |

CHECK DTC |

(a) Check for DTCs.

Chassis > Brake/EPB > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs are output |

A |

|

DTCs are not output |

B |

| A |

|

| B |

|

|

|

|

![2022 - 2024 MY RAV4 RAV4 HV [12/2021 - ]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (w/o Vacuum Brake Booster): UTILITY](/t3Portal/stylegraphics/info.gif)