| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM10000000214P4 |

| Model Year Start: 2022 | Model: RAV4 | Prod Date Range: [12/2021 - ] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (w/o Vacuum Brake Booster): C050C14; Left Rear Wheel Speed Sensor Circuit Short to Ground or Open; 2022 - 2024 MY RAV4 RAV4 HV [12/2021 - ] | ||

|

DTC |

C050C14 |

Left Rear Wheel Speed Sensor Circuit Short to Ground or Open |

DESCRIPTION

Refer to DTC C050C12.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Note |

|---|---|---|---|---|---|

|

C050C14 |

Left Rear Wheel Speed Sensor Circuit Short to Ground or Open |

An open in the skid control sensor signal circuit continues for 0.5 seconds or more. |

|

Comes on |

|

MONITOR DESCRIPTION

The No. 2 skid control ECU (brake actuator assembly) monitors the output of the speed sensors. When the output current of the speed sensor is excessively low, the MIL is illuminated and a DTC is stored.

MONITOR STRATEGY

|

Related DTCs |

C050E: Wheel speed sensor (RL) voltage circuit open |

|

Required Sensors/Components(Main) |

Speed sensor |

|

Required Sensors/Components(Related) |

No. 2 skid control ECU (brake actuator assembly) |

|

Frequency of Operation |

Continuous |

|

Duration |

0.528 seconds |

|

MIL Operation |

Immediately |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

Monitor runs whenever the following DTCs are not stored |

C050D (Case 4): Wheel speed sensor (RL) range/performance C050F: Wheel speed sensor (RL) voltage circuit high C137D: Brake system voltage input out of range high C14E7: Wheel speed sensor (RL) voltage circuit low |

|

All of the following conditions are met |

- |

|

+BS voltage |

17.4 V or less |

|

Command to wheel speed sensor power supply |

On |

|

Vehicle speed sensor supply voltage state |

Valid |

|

Wheel speed sensor current |

Less than 0.034 A |

TYPICAL MALFUNCTION THRESHOLDS

|

Wheel speed sensor current |

0.004 A or less |

COMPONENT OPERATING RANGE

|

Wheel speed sensor current |

Higher than 0.004 A |

CONFIRMATION DRIVING PATTERN

NOTICE:

When performing the normal judgment procedure, make sure that the driver door is closed and is not opened at any time during the procedure.

HINT:

- After repair has been completed, clear the DTC and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- When clearing the permanent DTCs, refer to the "CLEAR PERMANENT DTC" procedure.

- Connect the GTS to the DLC3.

- Turn the ignition switch to ON and turn the GTS on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off.

- Turn the ignition switch to ON (READY) and turn the GTS on.

-

Wait for 2 seconds or more. [*]

HINT:

[*]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Enter the following menus: Chassis / Brake/EPB / Utility / All Readiness.

-

Check the DTC judgment result.

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE, perform driving pattern again.

WIRING DIAGRAM

Refer to DTC C050C12.

CAUTION / NOTICE / HINT

NOTICE:

- After replacing the No. 2 skid control ECU (brake actuator assembly), perform "Calibration" after performing "Reset Memory".

- After replacing or removing and installing a skid control sensor, perform Dealer Mode (Signal Check) inspection to confirm that the skid control sensors are operating correctly.

PROCEDURE

|

1. |

READ VALUE USING GTS (MOMENTARY INTERRUPTION) |

(a) Select the line graph display on the GTS.

(b) Check for any momentary interruption in the wire harness and connector.

Chassis > Brake/EPB > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

RL Speed Open |

Momentary interruption of rear skid control sensor LH pulse input to ECU |

Normal / Under intermittent |

Normal: Normal Under intermittent: Momentary interruption |

- |

|

RL Speed Sensor Voltage Open |

Rear skid control sensor LH voltage open detection |

Normal / Under intermittent |

Normal: Normal Under intermittent: Momentary interruption |

- |

Chassis > Brake/EPB > Data List

|

Tester Display |

|---|

|

RL Speed Open |

|

RL Speed Sensor Voltage Open |

OK:

Normal (There are no momentary interruptions.)

NOTICE:

Perform the above inspection before removing the sensor and connector.

| OK |

|

|

|

2. |

INSPECT NO. 2 PARKING BRAKE WIRE ASSEMBLY |

|

(a) Turn the ignition switch off. |

|

(b) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

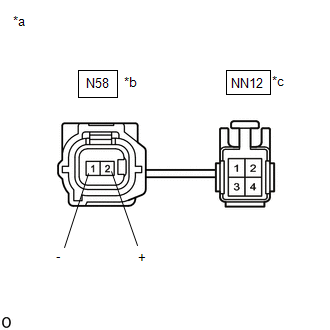

(c) Disconnect the N58 and NN12 skid control sensor wire LH (No. 2 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

N58-2 (+) - NN12-3 |

Always |

Below 1 Ω |

|

N58-2 (+) or NN12-3 - Body ground and other terminals |

Always |

10 kΩ or higher |

|

N58-1 (-) - NN12-4 |

Always |

Below 1 Ω |

|

N58-1 (-) or NN12-4 - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

REPLACE NO. 2 PARKING BRAKE WIRE ASSEMBLY |

|

|

3. |

CHECK HARNESS AND CONNECTOR (NO. 2 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A105 No. 2 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

NN12-3 - A105-5 (RL+) |

Always |

Below 1 Ω |

|

NN12-3 or A105-5 (RL+) - Body ground |

Always |

10 kΩ or higher |

|

NN12-4 - A105-4 (RL-) |

Always |

Below 1 Ω |

|

NN12-4 or A105-4 (RL-) - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

INSPECT BRAKE ACTUATOR ASSEMBLY (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Reconnect the A105 No. 2 skid control ECU (brake actuator assembly) connector. |

|

(b) Reconnect the NN12 skid control sensor wire LH (No. 2 parking brake wire assembly) connector.

(c) Turn the ignition switch to ON.

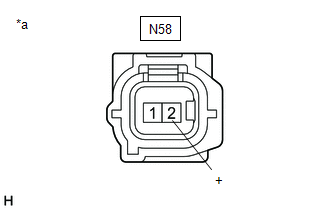

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

N58-2 (+) - Body ground |

Ignition switch ON |

11 to 14 V |

| OK |

|

| NG |

|

|

|

|

![2022 MY RAV4 RAV4 HV [12/2021 - 10/2022]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (w/o Vacuum Brake Booster): C050C12; Left Rear Wheel Speed Sensor Circuit Short to Battery](/t3Portal/stylegraphics/info.gif)