- Short to ground

- +B short

| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001L94H |

| Model Year Start: 2020 | Model: RAV4 | Prod Date Range: [10/2019 - 12/2021] |

| Title: PARK ASSIST / MONITORING: PARKING SUPPORT BRAKE SYSTEM (for Gasoline Model): U117787,U117887; Lost Communication with Side Obstacle Detection Control Module "A" (ch2) Missing Message; 2020 - 2021 MY RAV4 [10/2019 - 12/2021] | ||

|

DTC |

U117787 |

Lost Communication with Side Obstacle Detection Control Module "A" (ch2) Missing Message |

|

DTC |

U117887 |

Lost Communication with Side Obstacle Detection Control Module "B" (ch2) Missing Message |

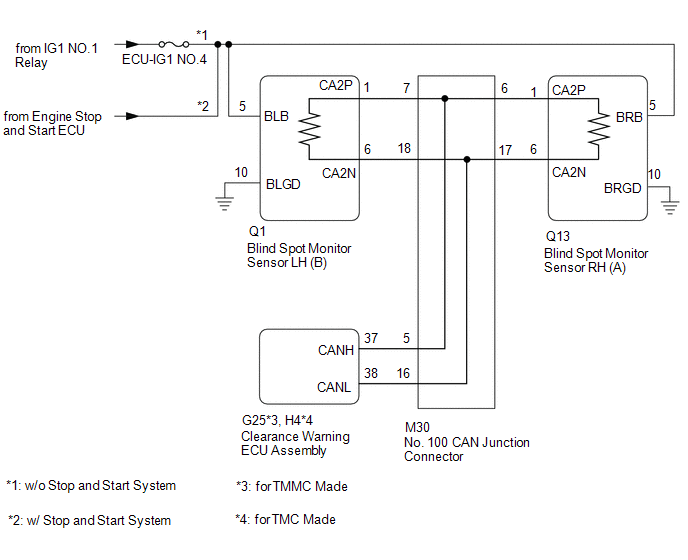

DESCRIPTION

This DTC is output when the clearance warning ECU assembly detects lost communication with the blind spot monitor sensor.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

U117787 |

Lost Communication with Side Obstacle Detection Control Module "A" (ch2) Missing Message |

The clearance warning ECU assembly is unable to receive communication from the blind spot monitor sensor RH (A) |

|

|

U117887 |

Lost Communication with Side Obstacle Detection Control Module "B" (ch2) Missing Message |

The clearance warning ECU assembly is unable to receive communication from the blind spot monitor sensor LH (B) |

|

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure. (w/o Stop and Start System)

- Before measuring the resistance of the CAN bus, turn the engine switch off and leave the vehicle for 1 minute or more without operating the key or any switches, or opening or closing the doors. After that, disconnect the cable from the negative (-) battery terminal and leave the vehicle for 1 minute or more before measuring the resistance.

- After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work.

HINT:

- Operating the engine switch, any other switches or a door triggers related ECU and sensor communication on the CAN. This communication will cause the resistance value to change.

- Even after DTCs are cleared, if a DTC is stored again after driving the vehicle for a while, the malfunction may be occurring due to vibration of the vehicle. In such a case, wiggling the ECUs or wire harness while performing the inspection below may help determine the cause of the malfunction.

PROCEDURE

|

1. |

CHECK FOR DTC |

(a) Check for DTCs.

Body Electrical > Clearance Warning > Trouble Codes

(b) Clear the DTCs.

Body Electrical > Clearance Warning > Clear DTCs

(c) Recheck for DTCs.

Body Electrical > Clearance Warning > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC U117787 only is output |

A |

|

DTC U117887 only is output |

B |

|

DTC U117787 and U117887 are output |

C |

| B |

|

| C |

|

|

|

2. |

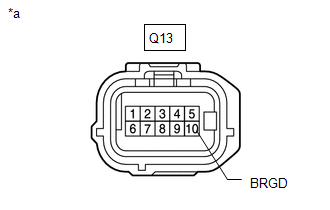

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR RH (A) - BODY GROUND) |

|

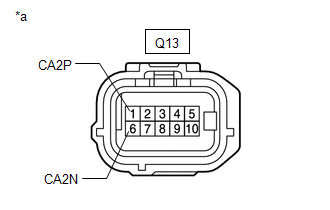

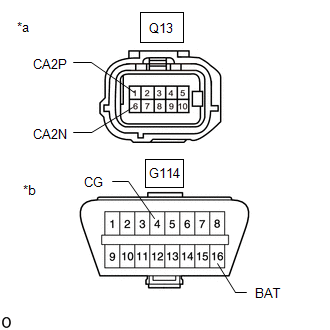

(a) Disconnect the blind spot monitor sensor RH (A) connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Q13-10 (BRGD) - Body ground |

Always |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

3. |

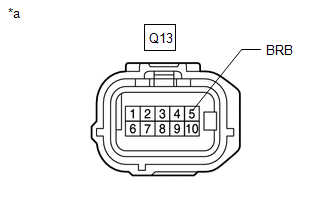

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR RH (A) POWER SOURCE) |

|

(a) Disconnect the blind spot monitor sensor RH (A) connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

*1: w/o Stop and Start System

*2: w/ Stop and Start System |

||

|

Q13-5 (BRB) - Body ground |

Engine switch on (IG) |

11 to 14 V*1 |

|

10.5 to 16 V*2 |

||

|

Q13-5 (BRB) - Body ground |

Engine switch off |

Below 1 V |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (w/o Stop and Start System) |

B |

|

NG (w/ Stop and Start System) |

C |

| A |

|

| B |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

| C |

|

|

4. |

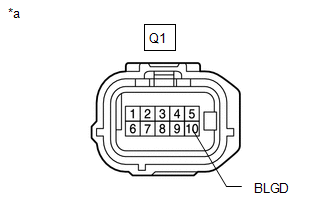

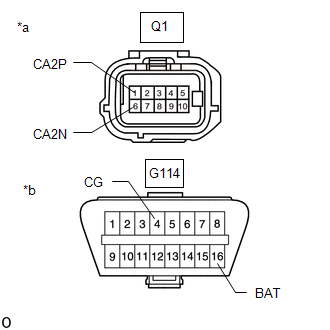

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR LH (B) - BODY GROUND) |

|

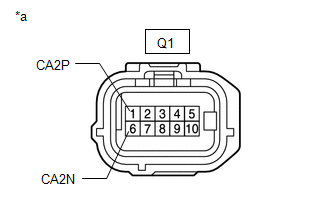

(a) Disconnect the blind spot monitor sensor LH (B) connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Q1-10 (BLGD) - Body ground |

Always |

Below 1 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

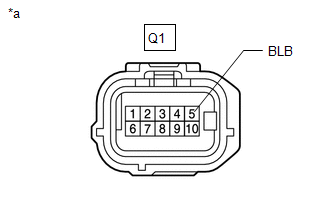

CHECK HARNESS AND CONNECTOR (BLIND SPOT MONITOR SENSOR LH (B) POWER SOURCE) |

|

(a) Disconnect the blind spot monitor sensor LH (B) connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Switch Condition |

Specified Condition |

|---|---|---|

|

*1: w/o Stop and Start System

*2: w/ Stop and Start System |

||

|

Q1-5 (BLB) - Body ground |

Engine switch on (IG) |

11 to 14 V*1 |

|

10.5 to 16 V*2 |

||

|

Q1-5 (BLB) - Body ground |

Engine switch off |

Below 1 V |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (w/o Stop and Start System) |

B |

|

NG (w/ Stop and Start System) |

C |

| A |

|

| B |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

| C |

|

|

6. |

CHECK CAN BUS MAIN WIRE |

|

(a) Turn the engine switch off. |

|

(b) Disconnect the cable from the negative (-) battery terminal.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

Result |

|---|---|---|---|

|

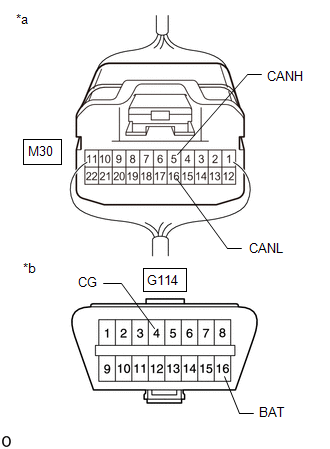

M30-5 (CANH) - M30-16 (CANL) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

Below 54 Ω: Short circuit between bus lines |

|

70 Ω or more: Open circuit in main bus lines |

|||

|

M30-5 (CANH) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

Below 200 Ω: CANH short to ground |

|

M30-16 (CANL) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

Below 200 Ω: CANL short to ground |

|

M30-5 (CANH) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Below 6 kΩ: CANH +B short |

|

M30-16 (CANL) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

Below 6 kΩ: CANL +B short |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

Open circuit in CAN main bus lines |

B |

|

Short circuit between bus lines |

C |

|

|

D |

| B |

|

| C |

|

| D |

|

|

|

7. |

CHECK FOR DTC |

(a) Clear the DTCs.

Body Electrical > Clearance Warning > Clear DTCs

(b) Check for DTCs.

Body Electrical > Clearance Warning > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTC U117787 and U117887 are not output |

A |

|

DTC U117787 and U117887 are output |

B |

| A |

|

| B |

|

|

8. |

CHECK FOR OPEN IN CAN BUS WIRE (NO. 100 JUNCTION CONNECTOR) |

(a) Disconnect the No. 100 CAN junction connector.

|

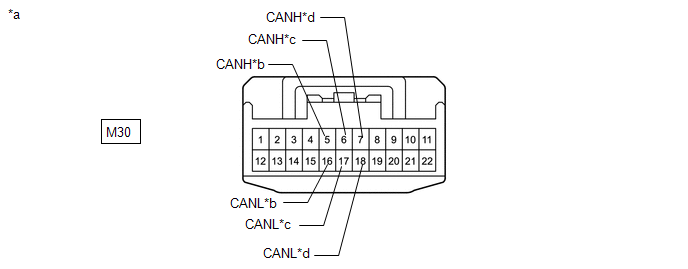

*a |

Front view of wire harness connector (to No. 100 CAN Junction Connector) |

*b |

to Clearance Warning ECU Assembly CAN Wire |

|

*c |

to Blind Spot Monitor Sensor RH (A) CAN Main Wire |

*d |

to Blind Spot Monitor Sensor LH (B) CAN Main Wire |

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M30-5 (CANH) - M30-16 (CANL) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

M30-6 (CANH) - M30-17 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

M30-7 (CANH) - M30-18 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (to blind spot monitor sensor LH (B) CAN main wire) |

B |

|

NG (to blind spot monitor sensor RH (A) CAN main wire) |

C |

|

NG (to clearance warning ECU assembly CAN wire) |

D |

| A |

|

REPLACE NO. 100 CAN JUNCTION CONNECTOR |

| C |

|

| D |

|

|

|

9. |

CHECK FOR OPEN IN CAN BUS MAIN WIRE (BLIND SPOT MONITOR SENSOR LH (B)) |

|

(a) Reconnect the M30 No. 100 CAN junction connector. |

|

(b) Disconnect the blind spot monitor sensor LH (B) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Q1-1 (CA2P) - Q1-6 (CA2N) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH (B) - NO. 100 CAN JUNCTION CONNECTOR) |

|

10. |

CHECK FOR OPEN IN CAN BUS MAIN WIRE (BLIND SPOT MONITOR SENSOR RH (A)) |

|

(a) Reconnect the M30 No. 100 CAN junction connector. |

|

(b) Disconnect the blind spot monitor sensor RH (A) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Q13-1 (CA2P) - Q13-6 (CA2N) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH (A) - NO. 100 CAN JUNCTION CONNECTOR) |

|

11. |

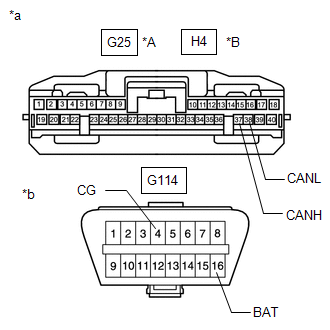

CHECK FOR OPEN IN CAN BUS WIRE (CLEARANCE WARNING ECU ASSEMBLY) |

|

(a) Reconnect the M30 No. 100 CAN junction connector. |

|

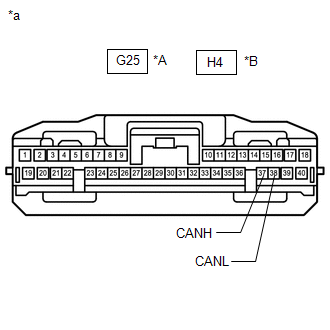

(b) Disconnect the clearance warning ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

for TMMC Made:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

G25-37 (CANH) - G25-38 (CANL) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

for TMC Made:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

H4-37 (CANH) - H4-38 (CANL) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BUS WIRE (CLEARANCE WARNING ECU ASSEMBLY - NO. 100 CAN JUNCTION CONNECTOR) |

|

12. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 100 JUNCTION CONNECTOR) |

(a) Disconnect the No. 100 CAN junction connector.

|

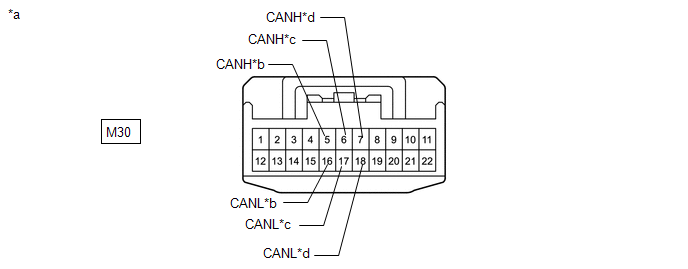

*a |

Front view of wire harness connector (to No. 100 CAN Junction Connector) |

*b |

to Clearance Warning ECU Assembly CAN Wire |

|

*c |

to Blind Spot Monitor Sensor RH (A) CAN Main Wire |

*d |

to Blind Spot Monitor Sensor LH (B) CAN Main Wire |

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M30-5 (CANH) - M30-16 (CANL) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

M30-6 (CANH) - M30-17 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

M30-7 (CANH) - M30-18 (CANL) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (to blind spot monitor sensor LH (B) CAN main wire) |

B |

|

NG (to blind spot monitor sensor RH (A) CAN main wire) |

C |

|

NG (to clearance warning ECU assembly CAN wire) |

D |

| A |

|

REPLACE NO. 100 CAN JUNCTION CONNECTOR |

| C |

|

| D |

|

|

|

13. |

CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR LH (B)) |

|

(a) Reconnect the M30 No. 100 CAN junction connector. |

|

(b) Disconnect the blind spot monitor sensor LH (B) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Q1-1 (CA2P) - Q1-6 (CA2N) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH (B) - NO. 100 CAN JUNCTION CONNECTOR) |

|

14. |

CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR RH (A)) |

|

(a) Reconnect the M30 No. 100 CAN junction connector. |

|

(b) Disconnect the blind spot monitor sensor RH (A) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Q13-1 (CA2P) - Q13-6 (CA2N) |

Cable disconnected from negative (-) battery terminal |

108 to 132 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH (A) - NO. 100 CAN JUNCTION CONNECTOR) |

|

15. |

CHECK FOR SHORT IN CAN BUS WIRES (CLEARANCE WARNING ECU ASSEMBLY) |

|

(a) Reconnect the M30 No. 100 CAN junction connector. |

|

(b) Disconnect the clearance warning ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

for TMMC Made:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

G25-37 (CANH) - G25-38 (CANL) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

for TMC Made:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

H4-37 (CANH) - H4-38 (CANL) |

Cable disconnected from negative (-) battery terminal |

54 to 69 Ω |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BUS WIRE (CLEARANCE WARNING ECU ASSEMBLY - NO. 100 CAN JUNCTION CONNECTOR) |

|

16. |

CHECK FOR SHORT IN CAN BUS WIRES (NO. 100 CAN JUNCTION CONNECTOR) |

(a) Disconnect the No. 100 CAN junction connector.

|

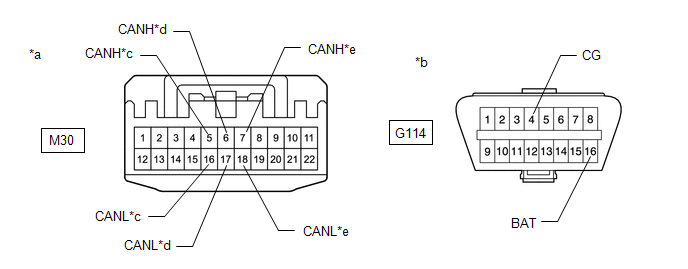

*a |

Front view of wire harness connector (to No. 100 CAN Junction Connector) |

*b |

Front view of DLC3 |

|

*c |

to Clearance Warning ECU Assembly CAN Wire |

*d |

to Blind Spot Monitor Sensor RH (A) CAN Main Wire |

|

*e |

to Blind Spot Monitor Sensor LH (B) CAN Main Wire |

- |

- |

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M30-5 (CANH) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

M30-16 (CANL) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

M30-5 (CANH) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

M30-16 (CANL) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

M30-6 (CANH) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

M30-17 (CANL) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

M30-6 (CANH) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

M30-17 (CANL) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

M30-7 (CANH) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

M30-18 (CANL) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

M30-7 (CANH) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

M30-18 (CANL) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

HINT:

Check for short that was confirmed to be a malfunction by confirming symptoms.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (to blind spot monitor sensor LH (B) CAN main wire) |

B |

|

NG (to blind spot monitor sensor RH (A) CAN main wire) |

C |

|

NG (to clearance warning ECU assembly CAN wire) |

D |

| A |

|

REPLACE NO. 100 CAN JUNCTION CONNECTOR |

| C |

|

| D |

|

|

|

17. |

CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR LH (B)) |

|

(a) Reconnect the M30 No. 100 CAN junction connector. |

|

(b) Disconnect the blind spot monitor sensor LH (B) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Q1-1 (CA2P) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

Q1-6 (CA2N) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

Q1-1 (CA2P) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

Q1-6 (CA2N) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR LH (B) - NO. 100 CAN JUNCTION CONNECTOR) |

|

18. |

CHECK FOR SHORT IN CAN BUS WIRES (BLIND SPOT MONITOR SENSOR RH (A)) |

|

(a) Reconnect the M30 No. 100 CAN junction connector. |

|

(b) Disconnect the blind spot monitor sensor RH (A) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Q13-1 (CA2P) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

Q13-6 (CA2N) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

Q13-1 (CA2P) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

Q13-6 (CA2N) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN MAIN WIRE OR CONNECTOR (BLIND SPOT MONITOR SENSOR RH (A) - NO. 100 CAN JUNCTION CONNECTOR) |

|

19. |

CHECK FOR SHORT IN CAN BUS WIRES (CLEARANCE WARNING ECU ASSEMBLY) |

|

(a) Reconnect the M30 No. 100 CAN junction connector. |

|

(b) Disconnect the clearance warning ECU connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

for TMMC Made:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

G25-37 (CANH) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

G25-38 (CANL) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

G25-37 (CANH) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

G25-38 (CANL) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

for TMC Made:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

H4-37 (CANH) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

H4-38 (CANL) - G114-4 (CG) |

Cable disconnected from negative (-) battery terminal |

200 Ω or higher |

|

H4-37 (CANH) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

|

H4-38 (CANL) - G114-16 (BAT) |

Cable disconnected from negative (-) battery terminal |

6 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE CAN BUS WIRE (CLEARANCE WARNING ECU ASSEMBLY - NO. 100 CAN JUNCTION CONNECTOR) |

|

|

|

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; INTRODUCTION: REPAIR INSTRUCTION: PRECAUTION](/t3Portal/stylegraphics/info.gif)