- Gas leak from exhaust system is repaired

- Replacement of throttle body with motor assembly

- Replacement of cam timing control motor with EDU assembly

- Removal and installation of a cam timing control motor with EDU assembly

- Replacement of camshaft timing gear assembly

- Removal and installation of a camshaft timing gear assembly

- Replacement of cylinder head sub-assembly

- Replacement of camshaft (for intake or exhaust camshaft)

- Replacement of camshaft timing exhaust gear assembly

- Replacement of port fuel injector assembly

- Replacement of direct fuel injector assembly

- Replacement of fuel pump assembly (for high pressure side)

- Replacement of spark plug

- Replacement of ignition coil assembly

- Replacement of EGR valve assembly

- Replacement of knock control sensor

- Replacement of air fuel ratio sensor (sensor 2)

| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001HGNP |

| Model Year Start: 2019 | Model: RAV4 HV | Prod Date Range: [02/2019 - 10/2019] |

| Title: A25A-FXS (ENGINE MECHANICAL): CYLINDER HEAD GASKET: REMOVAL; 2019 MY RAV4 HV [02/2019 - 10/2019] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during cylinder head gasket removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: When performing learning using the Techstream. | |||

|

Auxiliary battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane control system |

|

|

Parking support brake system (for HV model)* |

|||

|

Pre-collision system |

|||

|

Lighting system (EXT)(w/ AFS) |

|||

|

Memorize steering angle neutral point |

Parking assist monitor system |

||

|

Panoramic view monitor system (for HV model) |

|||

|

Reset back door close position |

Power back door system (for HV model) |

||

|

Back door lock initialization |

Power door lock control system |

||

|

Replacement of ECM (w/ Canister Pump Module) |

Perform Vehicle Identification Number (VIN) registration |

DTC P063051 is output |

|

|

Grille shutter switch specification infomation |

Vehicle control history (RoB) [X260E] is stored |

||

|

Replacement of ECM (w/o Canister Pump Module) |

Perform Vehicle Identification Number (VIN) registration |

DTC P063051 is output |

|

|

|

Inspection after repair |

|

|

|

Replacement of inverter with converter assembly |

Resolver learning |

|

|

|

Replacement of hybrid vehicle transaxle assembly |

|

||

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Panoramic view monitor system (for HV model) |

||

|

Replacement of headlight ECU sub-assembly LH |

|

Lighting system (EXT)(w/ Headlight ECU) |

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Perform headlight ECU sub-assembly LH initialization |

||

|

Front wheel alignment adjustment |

|

|

|

|

Front bumper assembly (Including removal and installation) |

Front television camera view adjustment |

Panoramic view monitor system (for HV model) |

|

NOTICE:

-

After the power switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the power switch off, be sure to wait for the time specified in the following table before disconnecting the cable from the negative (-) auxiliary battery terminal.

Waiting Time before Disconnecting Cable from Negative (-) Auxiliary Battery Terminal

System Name

See Procedure

Vehicle enrolled in Toyota Entune system or safety connect system

6 minutes

Vehicle not enrolled in Toyota Entune system and safety connect system

1 minute

- This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

PROCEDURE

1. INSTALL ENGINE ASSEMBLY TO ENGINE STAND

2. REMOVE ENGINE HANGERS

3. REMOVE COMPRESSOR ASSEMBLY WITH PULLEY

4. REMOVE NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY

5. REMOVE FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY)

6. REMOVE NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

7. REMOVE MANIFOLD STAY

8. REMOVE EXHAUST MANIFOLD

9. REMOVE THROTTLE BODY WITH MOTOR ASSEMBLY

10. REMOVE EGR COOLER ASSEMBLY

11. REMOVE NO. 1 EGR PIPE SUB-ASSEMBLY

12. REMOVE NO. 4 WATER BY-PASS HOSE

13. REMOVE EGR VALVE ASSEMBLY

14. REMOVE NO. 3 WATER BY-PASS PIPE

15. REMOVE NO. 2 WATER BY-PASS PIPE

16. REMOVE INTAKE MANIFOLD

17. REMOVE NO. 1 INTAKE MANIFOLD TO HEAD GASKET

18. DISCONNECT FUEL TUBE SUB-ASSEMBLY

19. REMOVE NO. 1 FUEL PIPE SUB-ASSEMBLY

20. REMOVE FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

21. REMOVE NO. 7 WATER BY-PASS HOSE

22. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

23. REMOVE NO. 1 DELIVERY PIPE SPACER

24. REMOVE INJECTOR VIBRATION INSULATOR

25. REMOVE NO. 5 ENGINE WIRE

26. REMOVE PORT FUEL INJECTOR ASSEMBLY

27. REMOVE FUEL DELIVERY PIPE

28. REMOVE DIRECT FUEL INJECTOR ASSEMBLY

29. REMOVE FUEL INJECTOR SEAL

30. REMOVE IGNITION COIL ASSEMBLY

31. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

32. REMOVE OIL PRESSURE CONTROL VALVE ASSEMBLY

33. REMOVE CAMSHAFT POSITION SENSOR (for Intake Side)

34. REMOVE CAMSHAFT POSITION SENSOR (for Exhaust Side)

35. REMOVE CAM TIMING OIL CONTROL SOLENOID ASSEMBLY

36. REMOVE CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY

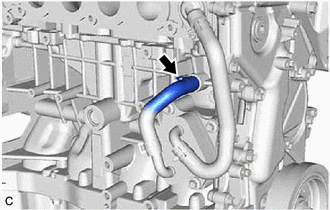

37. DISCONNECT NO. 1 WATER BY-PASS HOSE

|

(a) Slide the clip and disconnect the No. 1 water by-pass hose from the cylinder block sub-assembly. |

|

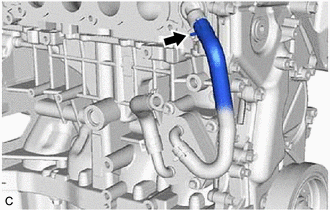

38. DISCONNECT NO. 2 WATER BY-PASS HOSE

|

(a) Slide the clip and disconnect the No. 2 water by-pass hose from the No. 1 water by-pass pipe sub-assembly. |

|

39. REMOVE CRANKSHAFT PULLEY ASSEMBLY

40. REMOVE WATER OUTLET

41. REMOVE OUTLET WATER BY-PASS SUB-ASSEMBLY

42. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

43. REMOVE SPARK PLUG TUBE GASKET

44. REMOVE ENGINE MOUNTING BRACKET RH

45. REMOVE NO. 2 TIMING CHAIN COVER ASSEMBLY

46. REMOVE TIMING CHAIN COVER OIL SEAL

47. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

48. REMOVE OIL PUMP DRIVE CHAIN SUB-ASSEMBLY

49. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY

50. REMOVE CHAIN SUB-ASSEMBLY

51. REMOVE NO. 1 CHAIN TENSIONER ASSEMBLY

52. REMOVE CHAIN TENSIONER SLIPPER

53. REMOVE NO. 1 CHAIN VIBRATION DAMPER

54. REMOVE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

55. REMOVE TIMING CHAIN COVER ASSEMBLY

56. REMOVE FUEL PUMP LIFTER GUIDE

57. REMOVE CAMSHAFT HOUSING SUB-ASSEMBLY

58. REMOVE CAMSHAFT BEARING CAP

59. REMOVE CAMSHAFT

60. REMOVE NO. 2 CAMSHAFT

61. REMOVE NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

62. REMOVE VALVE LASH ADJUSTER ASSEMBLY

63. REMOVE VALVE STEM CAP

64. REMOVE CYLINDER HEAD SUB-ASSEMBLY

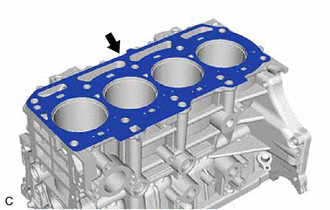

65. REMOVE CYLINDER HEAD GASKET

(a) Remove the cylinder head gasket from the cylinder block sub-assembly.

66. INSPECT CYLINDER HEAD SET BOLT

67. INSPECT CYLINDER HEAD SUB-ASSEMBLY

|

|

|

![2019 - 2022 MY RAV4 HV [02/2019 - 10/2022]; PARK ASSIST / MONITORING: PARKING SUPPORT BRAKE SYSTEM (for HV Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)