| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001G23D |

| Model Year Start: 2019 | Model: RAV4 | Prod Date Range: [11/2018 - 08/2020] |

| Title: THEFT DETERRENT / KEYLESS ENTRY: IMMOBILISER SYSTEM (for Gasoline Model without Smart Key System): Engine does not Start but Initial Combustion Occurs; 2019 - 2020 MY RAV4 [11/2018 - 08/2020] | ||

|

Engine does not Start but Initial Combustion Occurs |

DESCRIPTION

If the key ID codes of the door control transmitter assembly and transponder key ECU assembly match, the immobiliser system is unset and the engine start permission signal is sent to the ECM. When the ID codes of the transponder key ECU assembly and ECM match, the engine starts.

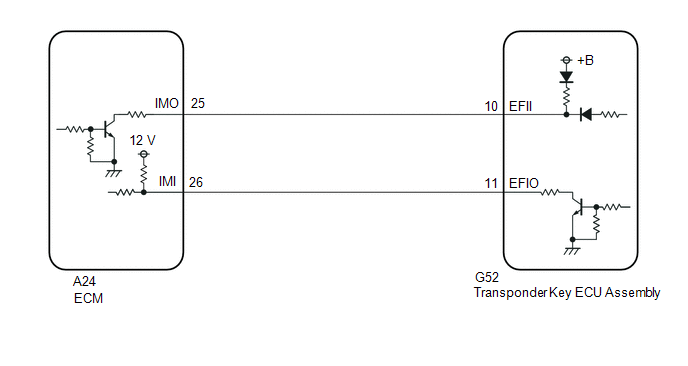

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Before replacing the transponder key ECU assembly or ECM, refer to the Registration.

- Make sure that no DTCs are output. If any DTCs are output, proceed to the Diagnostic Trouble Code Chart.

- After completing repairs, confirm that the problem does not recur.

- After repair, confirm that no DTCs are output by performing "DTC Output Confirmation Operation".

PROCEDURE

|

1. |

CHECK FOR DTC |

(a) Connect the Techstream to the DLC3.

(b) Turn the ignition switch to ON.

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical or Powertrain / Immobiliser or Engine / Trouble Codes.

(e) Check for DTCs.

Body Electrical > Immobiliser > Trouble Codes

Powertrain > Engine > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

DTCs are not output |

A |

|

DTCs are output |

B |

| B |

|

|

|

2. |

READ VALUE USING TECHSTREAM (IMMOBILISER FUEL CUT STARTS) |

(a) Enter the following menus: Powertrain / Engine / Data List.

(b) Read the Data List according to the display on the Techstream.

Powertrain > Engine > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Immobiliser Fuel Cut Status |

Status of immobiliser system fuel cut |

ON or OFF |

OFF: Fuel cut off ON: Fuel cut on |

- |

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Immobiliser Fuel Cut Status |

OK:

OFF is displayed after the engine is started.

| OK |

|

GO TO SFI SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING) w/ Canister Pump Module: w/o Canister Pump Module: |

|

|

3. |

CHECK WHETHER ENGINE STARTS |

(a) Check that the engine starts 5 seconds after the ignition switch was turned to ON.

OK:

Engine starts normally.

| OK |

|

|

|

4. |

CHECK ECM (TERMINAL EFII AND EFIO) |

(a) Using an oscilloscope, check the waveform.

|

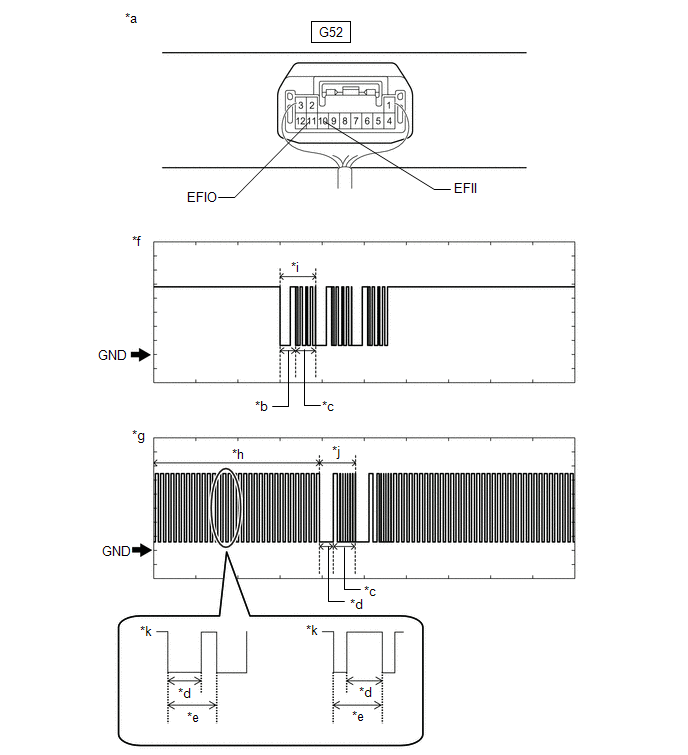

*a |

Component with harness connected (Transponder Key ECU Assembly) |

*b |

Approximately 160 ms. |

|

*c |

Approximately 270 ms. |

*d |

Approximately 40 ms. |

|

*e |

Approximately 60 ms. |

*f |

IMO Waveform |

|

*g |

IMI Waveform |

*h |

Waveform A |

|

*i |

Waveform B |

*j |

Waveform C |

|

*k |

Waveform A (detail) |

- |

- |

NOTICE:

The waveform shown in the illustration is an example for reference only. Noise, chattering, etc. are not shown.

Measurement Condition:

|

Tester Connection |

Condition |

Tool Setting |

Specified Condition |

|---|---|---|---|

|

G52-10 (EFII) - Body ground |

Within 3 seconds of engine start or within 3 seconds of ignition switch turned ON after cable disconnected and reconnected to battery |

2 V/DIV., 500 ms./DIV. |

Pulse generation (See waveform B) |

|

G52-11 (EFIO) - Body ground |

Within 3 seconds of engine start or within 3 seconds of ignition switch turned ON after cable disconnected and reconnected to battery |

2 V/DIV., 500 ms./DIV. |

Pulse generation (See waveform A and C) |

|

Result |

Proceed to |

|---|---|

|

Normal waveform |

A |

|

Waveform A is not output, or has abnormal wavelength or shape |

B |

|

Waveform B is not output, or has abnormal wavelength or shape |

C |

|

Waveform C is not output, or has abnormal wavelength or shape |

D |

| B |

|

| C |

|

| D |

|

|

|

5. |

REGISTER ECU COMMUNICATION ID (TRANSPONDER KEY ECU ASSEMBLY - ECM) |

(a) Register the communication ID between the transponder key ECU assembly and ECM.

|

|

6. |

CHECK WHETHER ENGINE STARTS |

(a) Check that the engine starts 5 seconds after the ignition switch was turned to ON.

OK:

Engine starts normally.

| OK |

|

END (COMMUNICATION ID WAS NOT REGISTERED) |

| NG |

|

|

7. |

CHECK HARNESS AND CONNECTOR (TRANSPONDER KEY ECU ASSEMBLY - ECM) |

(a) Disconnect the G52 transponder key ECU assembly connector.

(b) Disconnect the A24 ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

G52-10 (EFII) - A24-25 (IMO) |

Always |

Below 1 Ω |

|

G52-11 (EFIO) - A24-26 (IMI) |

Always |

Below 1 Ω |

|

G52-10 (EFII) or A24-25 (IMO) - Other terminals and body ground |

Always |

10 kΩ or higher |

|

G52-11 (EFIO) or A24-26 (IMI) - Other terminals and body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

8. |

REPLACE TRANSPONDER KEY ECU ASSEMBLY |

(a) Replace the transponder key ECU assembly with a new one.

|

|

9. |

REGISTER RECOGNITION CODE |

(a) Register the recognition codes to the ECUs.

|

|

10. |

REGISTER ECU COMMUNICATION ID |

(a) Register the ECU communication ID codes.

|

|

11. |

CHECK WHETHER ENGINE STARTS |

(a) Check that the engine starts.

OK:

Engine starts normally.

| OK |

|

END (TRANSPONDER KEY ECU ASSEMBLY WAS DEFECTIVE) |

| NG |

|

GO TO SFI SYSTEM (HOW TO PROCEED WITH TROUBLESHOOTING) w/ Canister Pump Module: w/o Canister Pump Module: |

|

|

|

![2019 - 2022 MY RAV4 [11/2018 - 10/2022]; THEFT DETERRENT / KEYLESS ENTRY: IMMOBILISER SYSTEM (for Gasoline Model without Smart Key System): REGISTRATION](/t3Portal/stylegraphics/info.gif)