| Last Modified: 01-30-2024 | 6.11:8.1.0 | Doc ID: RM100000001FANZ |

| Model Year Start: 2019 | Model: RAV4 | Prod Date Range: [11/2018 - 08/2020] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING UNIT (for A25A-FKS): INSTALLATION; 2019 - 2020 MY RAV4 [11/2018 - 08/2020] | ||

INSTALLATION

CAUTION / NOTICE / HINT

HINT:

A bolt without a torque specification is shown in the standard bolt chart.

PROCEDURE

1. INSTALL COOLER UNIT DRAIN HOSE GROMMET

2. INSTALL NO. 1 AIR DUCT SUB-ASSEMBLY (for TMC Made)

3. INSTALL NO. 3 AIR DUCT SUB-ASSEMBLY (for TMMC Made)

HINT:

- Perform this procedure only when removal/installation of the No. 3 air duct sub-assembly is necessary.

- Use the same procedure described as for the No. 1 air duct sub-assembly (for TMC Made).

4. INSTALL AIR CONDITIONING UNIT ASSEMBLY

5. INSTALL ID CODE BOX (IMMOBILIZER CODE ECU) (w/ ID Code Box)

6. INSTALL TRANSPONDER KEY ECU (IMMOBILIZER CODE ECU) (w/ Transponder ECU)

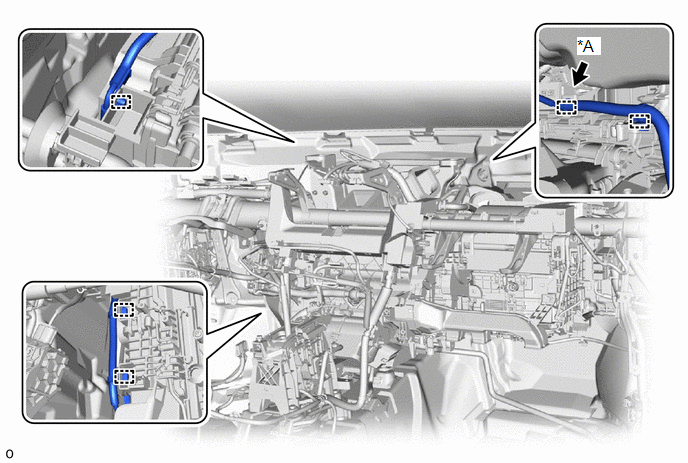

7. CONNECT INSTRUMENT PANEL WIRE

(a) Attach the clamp.

|

*A |

w/ ECU |

- |

- |

(b) Connect the connector.

8. INSTALL AIR CONDITIONING AMPLIFIER ASSEMBLY

9. INSTALL INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONING UNIT ASSEMBLY

10. INSTALL HEATER GROMMET

11. CONNECT DRAIN COOLER HOSE

12. TEMPORARILY INSTALL NO. 2 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

13. TEMPORARILY INSTALL NO. 1 INSTRUMENT PANEL BRACE SUB-ASSEMBLY

14. TIGHTEN INSTRUMENT PANEL REINFORCEMENT ASSEMBLY WITH AIR CONDITIONING UNIT ASSEMBLY

15. CONNECT INSTRUMENT PANEL WIRE

16. INSTALL ECU INTEGRATION BOX RH

17. INSTALL DOOR CONTROL BATTERY (w/ Door Control Battery)

18. CONNECT INSTRUMENT PANEL WIRE

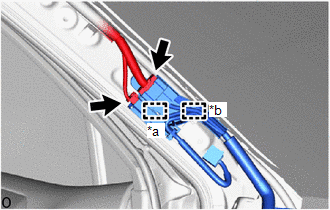

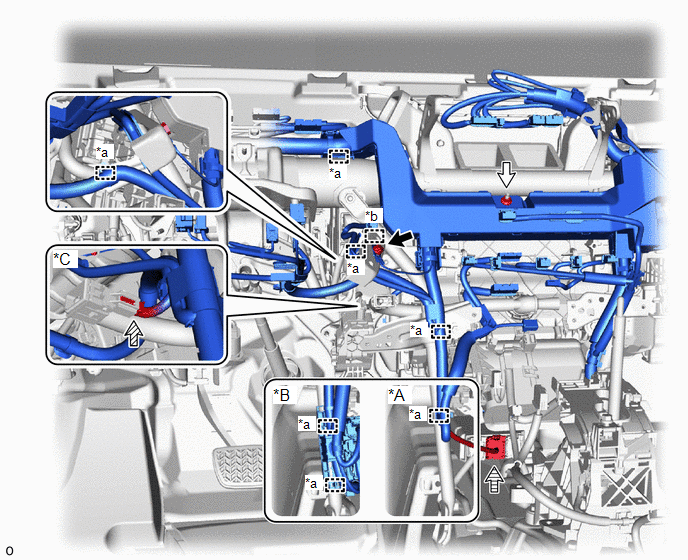

(a) Connect the lever connector.

|

*A |

for Type A |

*B |

for Type B |

|

*C |

for Automatic Air Conditioning System |

- |

- |

|

*a |

Clamp |

*b |

Guide |

|

Bolt |

|

Nut |

|

Connector |

|

Lever Connector |

(b) Attach the clamp.

(c) Connect the connector.

(d) Attach the guide.

(e) Connect the ground wire with the bolt.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

(f) Install the nut.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(g) Attach the clamp.

|

*a |

Clamp |

*b |

Guide |

(h) Attach the guide.

(i) Connect the 3 ground wires with the 3 bolts.

Torque:

8.5 N·m {87 kgf·cm, 75 in·lbf}

|

(j) Connect the 2 connectors. |

|

(k) Attach the guide and clamp.

19. INSTALL INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY WITH MAIN BODY ECU

20. INSTALL NO. 3 INSTRUMENT PANEL TO COWL BRACE SUB-ASSEMBLY (for TMC Made)

21. INSTALL CENTER INSTRUMENT PANEL BRACKET SUB-ASSEMBLY (for TMMC Made)

HINT:

Use the same procedure described as for the No. 3 instrument panel to cowl brace sub-assembly (for TMC Made).

22. INSTALL NO. 2 HEATER TO REGISTER DUCT SUB-ASSEMBLY

23. INSTALL NO. 1 CONSOLE BOX DUCT (w/ Rear Register Duct)

24. INSTALL REAR NO. 3 AIR DUCT (for TMC Made)

25. INSTALL REAR NO. 2 AIR DUCT (for TMMC Made)

HINT:

Use the same procedure described as for the rear No. 3 air duct (for TMC Made).

26. INSTALL REAR NO. 4 AIR DUCT (for TMC Made)

27. INSTALL REAR NO. 4 AIR DUCT (for TMMC Made)

HINT:

Use the same procedure described as for the rear No. 4 air duct (for TMC Made).

28. INSTALL REAR NO. 1 AIR DUCT

HINT:

Use the same procedure described as for the rear No. 3 air duct (for TMC Made).

29. INSTALL REAR NO. 2 AIR DUCT (for TMC Made)

HINT:

Use the same procedure described as for the rear No. 4 air duct (for TMC Made).

30. INSTALL REAR NO. 3 AIR DUCT (for TMMC Made)

HINT:

Use the same procedure described as for the rear No. 4 air duct (for TMC Made).

31. INSTALL NO. 3 DASH PANEL INSULATOR PAD

32. INSTALL FRONT FLOOR FRONT CARPET ASSEMBLY

33. INSTALL FRONT FLOOR CAUTION PLATE COVER (w/ Cover)

34. INSTALL ACCELERATOR PEDAL ASSEMBLY

35. INSTALL ACCELERATOR PEDAL PAD

36. INSTALL LOWER CENTER PILLAR GARNISH LH

(a) Install the lower center pillar garnish LH.

(b) Return the front door opening trim weatherstrip LH to its original position.

(c) Return the rear door opening trim weatherstrip LH to its original position.

37. INSTALL FRONT SEAT OUTER BELT ASSEMBLY LH

38. INSTALL REAR DOOR SCUFF PLATE LH

39. INSTALL LOWER CENTER PILLAR GARNISH RH

HINT:

Use the same procedure described as for the lower center pillar garnish LH.

40. INSTALL FRONT SEAT OUTER BELT ASSEMBLY RH

HINT:

Use the same procedure described as for the front seat outer belt assembly LH.

41. INSTALL REAR DOOR SCUFF PLATE RH

HINT:

Use the same procedure described as for the rear door scuff plate LH.

42. INSTALL OUTER LAP BELT ANCHOR COVER

43. INSTALL NAVIGATION ECU WITH BRACKET (w/ Navigation System)

44. INSTALL DCM (TELEPHONE TRANSCEIVER ASSEMBLY) WITH BRACKET (w/ DCM)

(a) w/ Navigation System:

(b) w/o Navigation System:

45. INSTALL STEERING COLUMN ASSEMBLY

46. INSTALL INSTRUMENT PANEL SAFETY PAD ASSEMBLY

47. INSTALL FRONT SEAT ASSEMBLY LH

(a) for Manual Seat:

(b) for Power Seat:

48. INSTALL FRONT SEAT ASSEMBLY RH

HINT:

Use the same procedure as for the LH side.

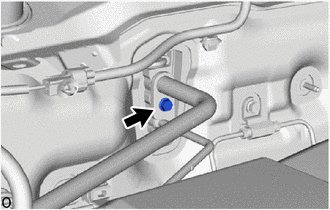

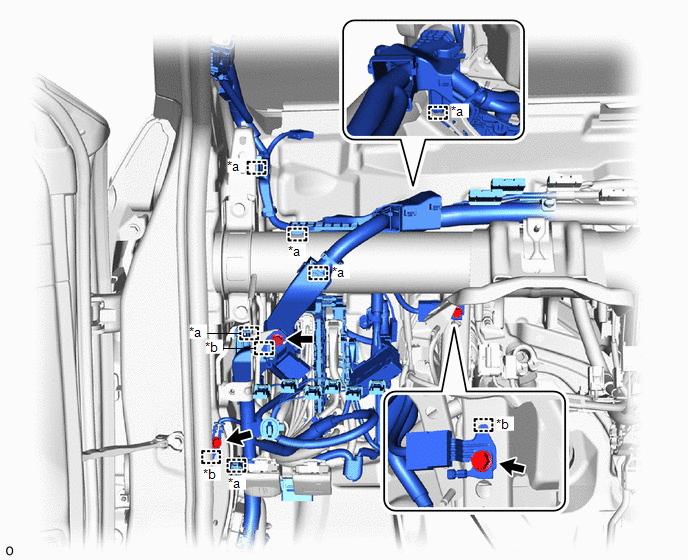

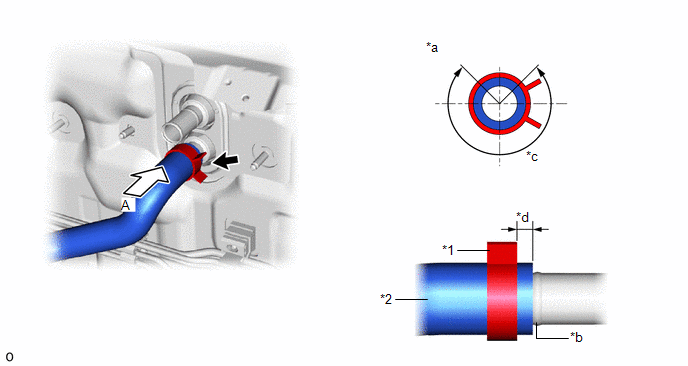

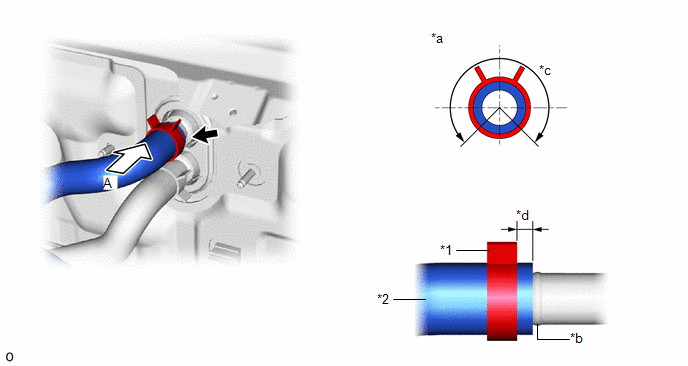

49. CONNECT INLET HEATER WATER HOSE

(a) Connect the inlet heater water hose as shown in the illustration.

NOTICE:

- Do not apply excessive force to the inlet heater water hose.

- Make sure the inlet heater water hose is securely inserted to the stopper. However, If the end of the inlet heater water hose is cut diagonally, it is acceptable for the entire circumference of the tip to not contact the stopper.

- Connect the inlet heater water hose so that its marking faces the top of the vehicle.

|

*1 |

Hose Clip |

*2 |

Inlet Heater Water Hose |

|

*a |

View A |

*b |

Stopper |

|

*c |

Hose Clip Installation Angle (270°) |

*d |

Hose Clip Installation Range (2 to 7 mm (0.0787 to 0.276 in.)) |

(b) Make sure to install the hose clip within the range shown in the illustration.

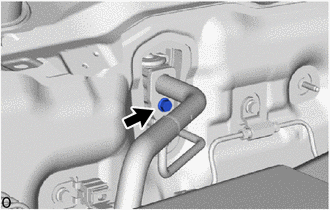

50. CONNECT OUTLET HEATER WATER HOSE

(a) Connect the outlet heater water hose as shown in the illustration.

NOTICE:

- Do not apply excessive force to the outlet heater water hose.

- Make sure the outlet heater water hose is securely inserted to the stopper. However, If the end of the outlet heater water hose is cut diagonally, it is acceptable for the entire circumference of the tip to not contact the stopper.

- Connect the outlet heater water hose so that its marking faces the top of the vehicle.

|

*1 |

Hose Clip |

*2 |

Outlet Heater Water Hose |

|

*a |

View A |

*b |

Stopper |

|

*c |

Hose Clip Installation Angle (270°) |

*d |

Hose Clip Installation Range (2 to 7 mm (0.0787 to 0.276 in.)) |

(b) Make sure to install the hose clip within the range shown in the illustration.

NOTICE:

Make sure that the hose clamps do not contact each other.

51. CONNECT AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY (w/o Sub-cool Accelerator)

(a) Remove the vinyl tape wrapped around the connection of the air conditioning tube and accessory assembly and the air conditioning tube and accessory assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the air conditioning tube and accessory assembly.

Compressor Oil:

|

Refrigerant |

Compressor Oil |

|---|---|

|

HFC-134a (R134a) |

ND-OIL 8 or equivalent |

|

HFO-1234yf (R1234yf) |

ND-OIL 12 or equivalent |

(c) Install the O-ring to the air conditioning tube and accessory assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free from foreign matter.

(d) Connect the air conditioning tube and accessory assembly.

NOTICE:

- Do not apply excessive force to the air conditioning tube and accessory assembly.

- Make sure not to cut the O-ring while installing it. (Cut O-rings cannot be installed)

52. CONNECT SUCTION PIPE SUB-ASSEMBLY (for TMC Made without Sub-cool Accelerator)

(a) Remove the vinyl tape wrapped around the connection of the suction pipe sub-assembly and suction pipe sub-assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the suction pipe sub-assembly.

Compressor Oil:

|

Refrigerant |

Compressor Oil |

|---|---|

|

HFC-134a (R134a) |

ND-OIL 8 or equivalent |

|

HFO-1234yf (R1234yf) |

ND-OIL 12 or equivalent |

(c) Install the O-ring to the suction pipe sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(d) Connect the suction pipe sub-assembly.

NOTICE:

- Do not apply excessive force to the suction pipe sub-assembly.

- Make sure not to cut the O-ring while installing it. (Cut O-rings cannot be installed)

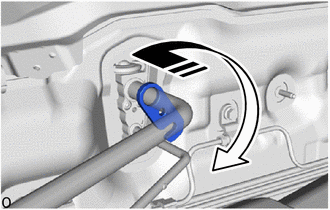

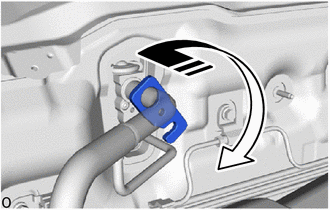

(e) Rotate the 1-point tightening plate as shown in the illustration.

|

Rotate in this Direction |

|

(f) Insert the tube joint into the fitting hole securely and install the bolt. Torque: 9.8 N·m {100 kgf·cm, 87 in·lbf} |

|

53. CONNECT SUCTION TUBE SUB-ASSEMBLY B (for TMMC Made without Sub-cool Accelerator)

HINT:

Use the same procedure described as for the suction pipe sub-assembly (for TMC Made without Sub-cool Accelerator).

54. CONNECT NO. 2 AIR CONDITIONING TUBE AND ACCESSORY ASSEMBLY (for TMC Made with Sub-cool Accelerator)

(a) Remove the vinyl tape wrapped around the connection of the No. 2 air conditioning tube and accessory assembly and the No. 2 air conditioning tube and accessory assembly.

(b) Sufficiently apply compressor oil to 2 new O-rings and the fitting surfaces of the No. 2 air conditioning tube and accessory assembly.

Compressor Oil:

ND-OIL 12 or equivalent

(c) Install the 2 O-rings to the No. 2 air conditioning tube and accessory assembly.

NOTICE:

Keep the O-rings and O-ring fitting surfaces free of foreign matter.

(d) Connect the No. 2 air conditioning tube and accessory assembly.

NOTICE:

- Do not apply excessive force to the No. 2 air conditioning tube and accessory assembly.

- Make sure not to cut the O-ring while installing it. (Cut O-rings cannot be installed)

(e) Rotate the 1-point tightening plate as shown in the illustration.

|

Rotate in this Direction |

|

(f) Insert the tube joint into the fitting hole securely and install the bolt. Torque: 9.8 N·m {100 kgf·cm, 87 in·lbf} |

|

55. CONNECT SUCTION TUBE SUB-ASSEMBLY B (for TMMC Made with Sub-cool Accelerator)

HINT:

Use the same procedure described as for the No. 2 air conditioning tube and accessory assembly (for TMC Made with Sub-cool Accelerator).

56. INSTALL HOLE PLUG

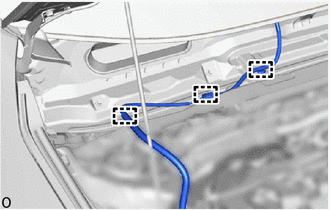

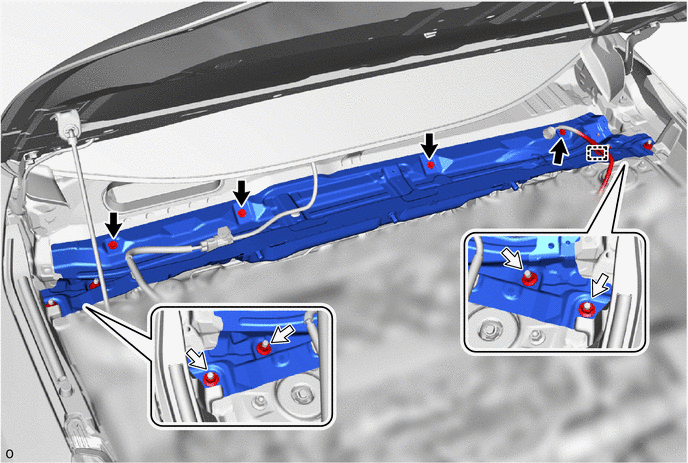

57. INSTALL COWL VENTILATOR PANEL SUB-ASSEMBLY

(a) Install the cowl ventilator panel sub-assembly with the 4 bolts and 4 nuts.

Torque:

Bolt :

5.5 N·m {56 kgf·cm, 49 in·lbf}

Nut :

21 N·m {214 kgf·cm, 15 ft·lbf}

|

Bolt |

|

Nut |

(b) Attach the clamp.

(c) w/ Windshield Deicer System:

|

(1) Attach the clamp. |

|

58. INSTALL COWL VENTILATOR SPLASH SHIELD (for TMC Made)

59. INSTALL COWL VENTILATOR SPLASH SHIELD (for TMMC Made)

HINT:

Use the same procedure described as for the cowl ventilator splash shield (for TMC Made).

60. INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY

61. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

(a) for HFC-134a (R134a):

(b) for HFO-1234yf (R1234yf):

62. ADD ENGINE COOLANT

63. INSPECT FOR COOLANT LEAK

64. WARM UP ENGINE

(a) for HFC-134a (R134a):

(b) for HFO-1234yf (R1234yf):

65. INSPECT FOR REFRIGERANT LEAK

(a) for HFC-134a (R134a):

(b) for HFO-1234yf (R1234yf):

|

|

|

![2019 - 2024 MY RAV4 RAV4 HV [11/2018 - ]; SPECIFICATIONS: STANDARD BOLT: SPECIFIED TORQUE FOR STANDARD BOLTS](/t3Portal/stylegraphics/info.gif)