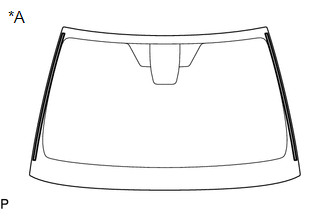

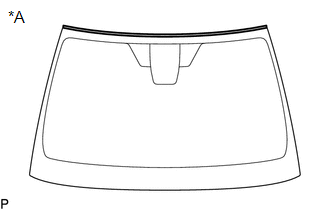

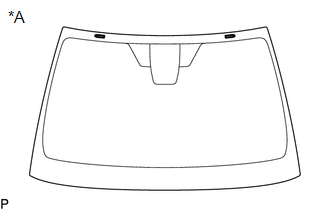

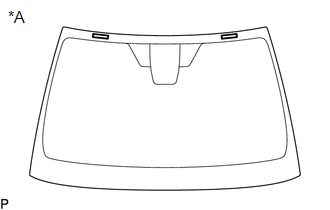

- Forward recognition camera

- Windshield glass

| Last Modified: 08-21-2023 | 6.11:8.1.0 | Doc ID: RM100000001YP7F |

| Model Year Start: 2022 | Model: Avalon HV | Prod Date Range: [08/2021 - ] |

| Title: WINDOW / GLASS: WINDSHIELD GLASS: REMOVAL; 2022 MY Avalon Avalon HV [08/2021 - ] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during windshield glass sub-assembly removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced (for Gasoline Model)

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: w/ Garage Door Opener System | |||

|

|

Adjust forward recognition camera |

|

|

|

Inner rear view mirror assembly* |

Register codes in the garage door opener system |

Garage door opener system |

|

|

Front passenger seat |

Zero point calibration (Occupant classification system) |

|

|

Necessary Procedure After Parts Removed/Installed/Replaced (for HV Model)

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *: w/ Garage Door Opener System | |||

|

Adjust forward recognition camera |

|

|

|

Inner rear view mirror assembly* |

Register codes in the garage door opener system |

Garage door opener system |

|

|

Front passenger seat |

Zero point calibration (Occupant classification system) |

|

|

NOTICE:

When replacing the windshield glass of a vehicle equipped with a forward recognition camera, make sure to use a Toyota genuine part. If a non-Toyota genuine part is used, the forward recognition camera may not be able to be installed due to a missing bracket. Also, the dynamic radar cruise control system, front camera system, lane tracing assist system, road sign assist system, pre-collision system or lighting system (EXT) may not operate properly due to a difference in the transmissivity or black ceramic border.

PROCEDURE

1. REMOVE LOWER WINDSHIELD OUTSIDE MOULDING LH

2. REMOVE LOWER WINDSHIELD OUTSIDE MOULDING RH

HINT:

Use the same procedure as for the LH side.

3. REMOVE FRONT WIPER ARM HEAD CAP

4. REMOVE FRONT WIPER ARM AND BLADE ASSEMBLY LH

5. REMOVE FRONT WIPER ARM AND BLADE ASSEMBLY RH

6. REMOVE FRONT FENDER TO COWL SIDE SEAL LH

7. REMOVE FRONT FENDER TO COWL SIDE SEAL RH

HINT:

Use the same procedure as for the LH side.

8. REMOVE COWL TOP VENTILATOR LOUVER SUB-ASSEMBLY

9. REMOVE INNER REAR VIEW MIRROR ASSEMBLY

10. REMOVE FORWARD RECOGNITION CAMERA

11. REMOVE ROOF HEADLINING ASSEMBLY

12. REMOVE WINDSHIELD GLASS SUB-ASSEMBLY

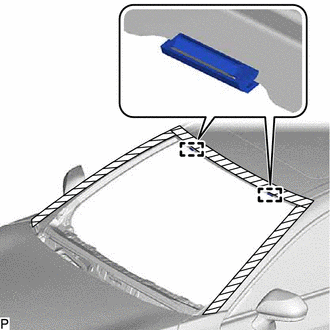

(a) Apply protective tape to the area around the installation position of the windshield glass sub-assembly on the vehicle body to prevent it from being scratched.

|

Protective Tape |

|

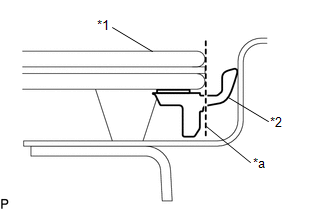

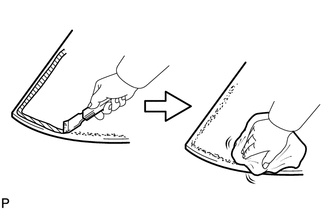

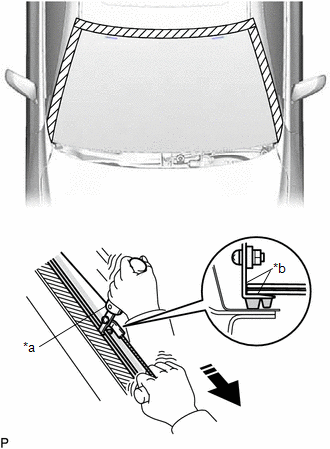

(b) Using a knife, cut off the windshield outside moulding as shown in the illustration. |

|

|

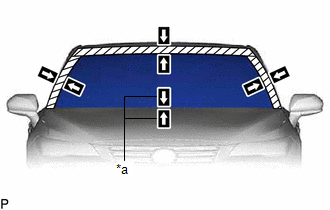

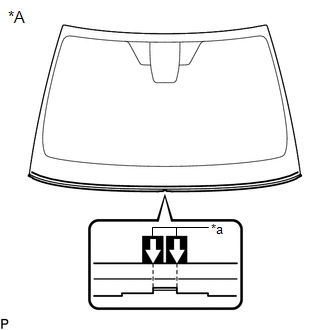

(c) Place matchmarks on the windshield glass sub-assembly and vehicle body at the locations indicated in the illustration. HINT: Matchmarks are not necessary if the windshield glass is not going to be reused. |

|

(d) When using a windshield knife:

(1) Apply soapy water to the area around the adhesive.

(2) Insert a windshield knife into the adhesive between the windshield glass sub-assembly and vehicle body.

|

*a |

Windshield Knife |

|

*b |

Aligned with Windshield Glass Sub-assembly |

|

Pull |

(3) While keeping the windshield knife perpendicular to the outer surface of the windshield glass sub-assembly, cut the adhesive by pulling the windshield knife around the windshield glass sub-assembly.

NOTICE:

- Do not pry the windshield glass sub-assembly with the windshield knife.

- Do not use a windshield knife to cut the adhesive on the lower side of the windshield glass sub-assembly.

- When separating the windshield glass sub-assembly, be careful not to damage the paint or interior and exterior ornaments.

HINT:

Insert the windshield knife in an area where the gap between windshield glass sub-assembly and vehicle body is large.

(e) When using piano wire:

|

(1) Pass a piano wire between the vehicle body and windshield glass sub-assembly from the interior. |

|

(2) Tie both wire ends to wooden blocks or similar objects that can serve as handles.

(3) Cut the adhesive by pulling the piano wire around the windshield glass sub-assembly.

NOTICE:

- When separating the windshield glass sub-assembly, be careful not to damage the paint or interior and exterior ornaments.

- To prevent the safety pad from being scratched when removing the windshield glass sub-assembly, place a plastic sheet between the piano wire and safety pad.

- Be careful not to damage the front window inner center moulding.

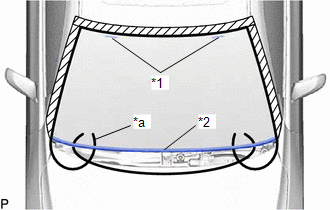

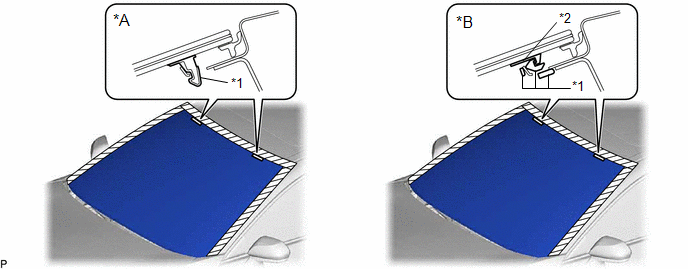

(f) Disengage the windshield glass stoppers.

|

*A |

for 1-piece Type |

*B |

for 2-piece Type |

|

*1 |

No. 1 Windshield Glass Stopper |

*2 |

No. 2 Windshield Glass Stopper |

NOTICE:

- The No. 1 windshield glass stoppers and No. 2 windshield glass stoppers are installed to the windshield glass sub-assembly as shown in the illustration. Be careful not to damage the windshield glass sub-assembly when cutting the adhesive.

- To prevent the windshield glass sub-assembly from falling when performing this operation, be sure to hold the windshield glass sub-assembly using suction cups.

HINT:

Depending on the vehicle, either 1-piece type or 2-piece type stoppers may be present.

(g) Using suction cups, remove the windshield glass sub-assembly.

NOTICE:

- Be careful not to drop the windshield glass sub-assembly.

- Leave as much adhesive on the vehicle body as possible when removing the windshield glass sub-assembly.

13. REMOVE WINDOW GLASS ADHESIVE DAM

(a) When reusing the windshield glass:

|

(1) Using a scraper, remove the window glass adhesive dam. NOTICE:

|

|

14. REMOVE NO. 2 WINDOW GLASS ADHESIVE DAM

(a) When reusing the windshield glass:

|

(1) Using a scraper, remove the 2 No. 2 window glass adhesive dams. NOTICE:

|

|

15. REMOVE WINDSHIELD OUTSIDE MOULDING

(a) When reusing the windshield glass:

|

(1) Using a scraper, remove the windshield outside moulding. NOTICE:

|

|

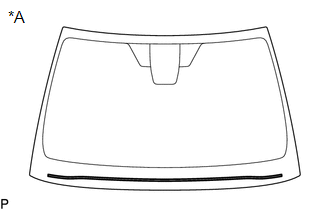

16. REMOVE NO. 1 WINDSHIELD GLASS STOPPER (for 1-piece Type)

(a) When reusing the windshield glass:

|

(1) Using a scraper, remove the 2 No. 1 windshield glass stoppers. NOTICE:

|

|

17. REMOVE NO. 2 WINDSHIELD GLASS STOPPER (for 2-piece Type)

(a) When reusing the windshield glass:

|

(1) Using a scraper, remove the 2 No. 2 windshield glass stoppers. NOTICE:

|

|

18. REMOVE NO. 1 WINDSHIELD GLASS STOPPER (for 2-piece Type)

|

(a) Remove the 2 No. 1 windshield glass stoppers from the vehicle body. NOTICE: Be sure to replace the No. 1 windshield glass stoppers with new ones. |

|

19. REMOVE FRONT WINDOW INNER CENTER MOULDING

HINT:

Perform the following procedure only when replacement of the front window inner center moulding is necessary.

|

(a) Place matchmarks on the windshield glass at the locations indicated in the illustration. |

|

(b) Using a scraper, remove the front window inner center moulding.

NOTICE:

- Be careful not to damage the windshield glass.

- Be sure to replace the front window inner center moulding with a new one.

20. CLEAN WINDSHIELD GLASS

(a) When reusing the windshield glass:

|

(1) Using a scraper, remove any remaining adhesive dam and adhesive residue from the windshield glass. NOTICE: Be careful not to damage the windshield glass. |

|

(2) Clean the outer circumference of the windshield glass with a non-residue solvent.

NOTICE:

- Do not touch the windshield glass surface after cleaning it.

- Even if using a new windshield glass, clean it with a non-residue solvent.

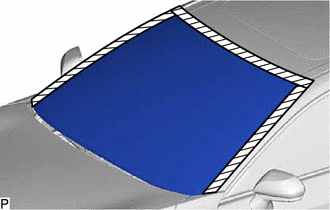

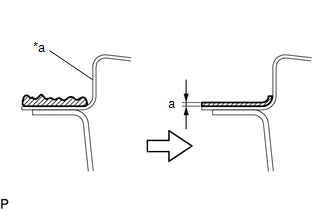

21. CLEAN VEHICLE BODY

(a) Clean and shape the contact surface of the vehicle body.

(1) Using a knife, cut off any excess adhesive on the contact surface of the vehicle body as shown in the illustration.

|

*a |

Vehicle Body |

|

Adhesive |

Standard Dimension:

|

Area |

Dimension |

|---|---|

|

a |

1.0 mm (0.0394 in.) or more |

NOTICE:

Be careful not to damage the vehicle body.

HINT:

Leave approximately 1.0 mm (0.0394 in.) of adhesive on the vehicle body.

(2) Clean the contact surface of the vehicle body with a piece of cloth saturated with non-residue solvent.

HINT:

Even if all of the adhesive has been removed, clean the vehicle body.

|

|

|

![2022 MY Avalon Avalon HV [08/2021 - ]; CRUISE CONTROL: FRONT CAMERA: TARGET ADJUSTMENT(ONE TIME RECOGNITION)](/t3Portal/stylegraphics/info.gif)