- Gas leak from exhaust system is repaired

- Replacement of engine coolant temperature sensor

| Last Modified: 08-21-2023 | 6.11:8.1.0 | Doc ID: RM100000001YL2B |

| Model Year Start: 2022 | Model: Avalon HV | Prod Date Range: [08/2021 - ] |

| Title: A25A-FXS (ENGINE MECHANICAL): REAR CRANKSHAFT OIL SEAL: REMOVAL; 2022 MY Avalon HV [08/2021 - ] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during rear crankshaft oil seal removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Auxiliary battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision System |

|||

|

Intelligent clearance sonar system* |

|||

|

Lighting System (for HV Model with Cornering Light) |

|||

|

Memorize steering angle neutral point |

Parking assist monitor system |

||

|

Panoramic view monitor system |

|||

|

Replacement of ECM |

Perform Vehicle Identification Number (VIN) registration |

MIL illuminates |

|

|

|

Inspection After Repair |

|

|

|

Replacement of inverter with converter assembly |

Resolver learning |

|

|

|

Replacement of hybrid vehicle transaxle assembly |

|

||

|

Front wheel alignment adjustment |

|

|

|

|

|

|

|

|

Suspension, tires, etc.*1 |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Replacement of front bumper assembly |

Front television camera view adjustment |

Panoramic view monitor system |

|

|

Suspension, tires, etc.*1 |

|

||

|

Synchronize the vehicle information |

Lighting system (for HV Model with Cornering Light) |

NOTICE:

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

PROCEDURE

1. REMOVE HYBRID VEHICLE TRANSAXLE ASSEMBLY

2. REMOVE TRANSMISSION INPUT DAMPER ASSEMBLY

(a) Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly horizontal.

- To prevent the No. 2 oil pan sub-assembly from deforming, do not place any attachments under the No. 2 oil pan sub-assembly of the engine assembly.

- Using an engine sling device and engine lift, secure the engine assembly before servicing.

|

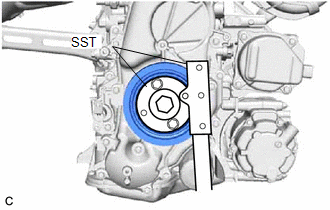

(b) Using SST, hold the crankshaft pulley assembly. SST: 09213-54015 SST: 09330-00021 |

|

|

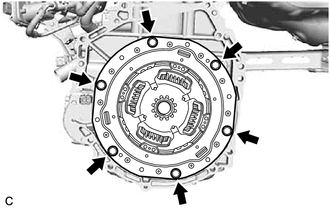

(c) Remove the 6 bolts and transmission input damper assembly from the flywheel sub-assembly. |

|

3. REMOVE FLYWHEEL SUB-ASSEMBLY

|

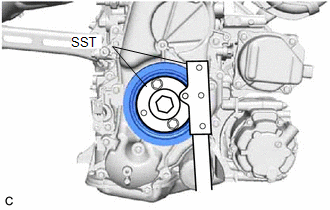

(a) Using SST, hold the crankshaft pulley assembly. SST: 09213-54015 SST: 09330-00021 |

|

|

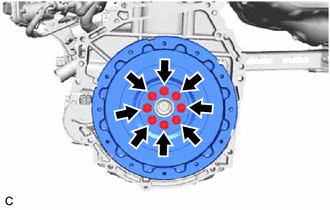

(b) Remove the 8 bolts and flywheel sub-assembly from the crankshaft. |

|

4. REMOVE NO. 1 CRANKSHAFT POSITION SENSOR PLATE

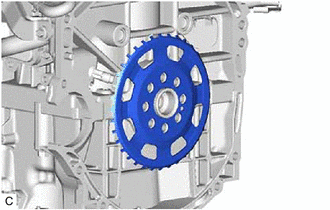

(a) Type A:

|

(1) Remove the No. 1 crankshaft position sensor plate. |

|

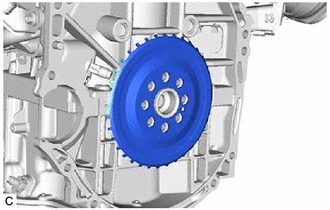

(b) Type B:

|

(1) Remove the No. 1 crankshaft position sensor plate. |

|

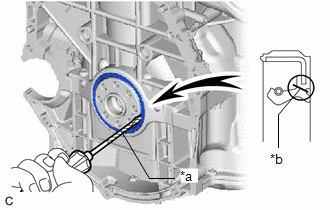

5. REMOVE REAR ENGINE OIL SEAL

|

(a) Using a knife, cut off the lip of the rear engine oil seal. |

|

(b) Using a screwdriver with its tip wrapped with protective tape, pry out the rear engine oil seal.

NOTICE:

Be careful not to damage the crankshaft.

|

|

|

![2022 MY Avalon Avalon HV [08/2021 - ]; PRE-COLLISION: PRE-COLLISION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)