| Last Modified: 09-10-2025 | 6.11:8.1.0 | Doc ID: RM100000001XNMY |

| Model Year Start: 2022 | Model: Avalon | Prod Date Range: [08/2021 - ] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model): C051249; Right Rear Wheel Speed Sensor Internal Electronic Failure; 2022 MY Avalon [08/2021 - ] | ||

|

DTC |

C051249 |

Right Rear Wheel Speed Sensor Internal Electronic Failure |

DESCRIPTION

When the system is starting up and the skid control ECU (brake actuator assembly) detects a speed sensor circuit malfunction via the speed sensor circuit self-diagnosis function, this DTC is stored.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

C051249 |

Right Rear Wheel Speed Sensor Internal Electronic Failure |

A circuit malfunction in the speed sensor is detected during the self test. |

|

- *1: for 2WD

- *2: for AWD

WIRING DIAGRAM

Refer to DTC C051212.

CAUTION / NOTICE / HINT

NOTICE:

- After replacing the skid control ECU (brake actuator assembly), perform acceleration sensor zero point calibration and system information memorization.

- After replacing or removing and installing a speed sensor, perform Dealer Mode (Signal Check) inspection to confirm that the speed sensors are operating correctly.

PROCEDURE

PROCEDURE

|

1. |

CHECK VEHICLE |

(a) Check the vehicle specification.

|

Result |

Proceed to |

|---|---|

|

for 2WD |

A |

|

for AWD |

B |

| B |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (SENSOR CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

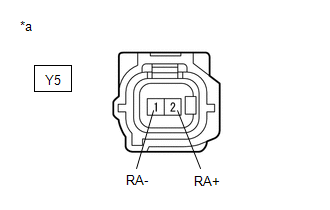

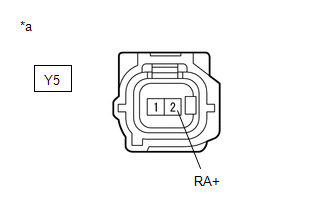

(b) Disconnect the Y5 rear speed sensor RH (rear axle hub and bearing assembly RH) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Y5-2 (RA+) - Y5-1 (RA-) |

Engine switch on (IG) |

11 to 14 V |

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (w/o AVS) |

B |

|

NG (w/ AVS) |

C |

| B |

|

| C |

|

|

|

3. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the Y5 rear speed sensor RH (rear axle hub and bearing assembly RH) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Y5-2 (RA+) - Body ground |

Engine switch off |

Below 1.5 V |

|

Result |

Proceed to |

|---|---|

|

OK (w/o AVS) |

A |

|

OK (w/ AVS) |

B |

|

NG (w/o AVS) |

C |

|

NG (w/ AVS) |

D |

| B |

|

| C |

|

| D |

|

|

|

4. |

INSPECT NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

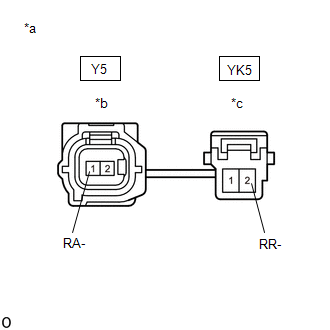

(b) Disconnect the Y5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

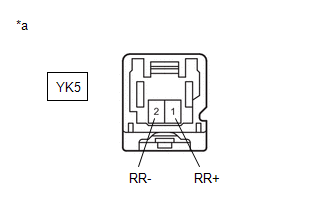

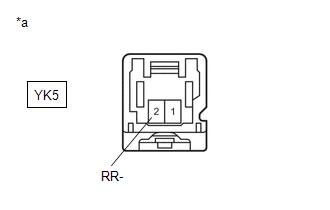

Y5-1 (RA-) or YK5-2 (RR-) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

|

5. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK5-2 (RR-) or A28-37 (RR-) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

6. |

INSPECT NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

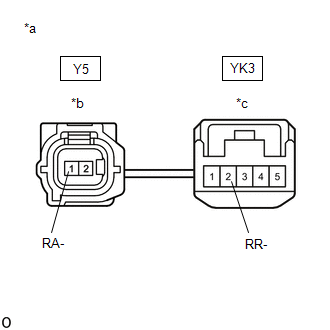

(b) Disconnect the Y5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

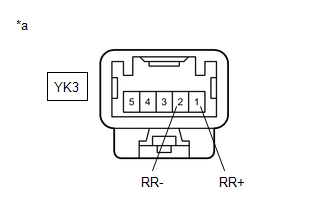

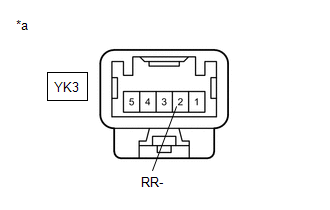

(c) Disconnect the YK3 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

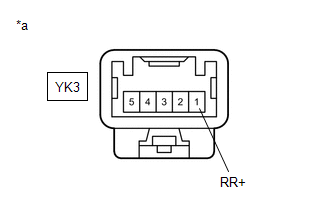

Y5-1 (RA-) or YK3-2 (RR-) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

|

7. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK3 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK3-2 (RR-) or A28-37 (RR-) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

8. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

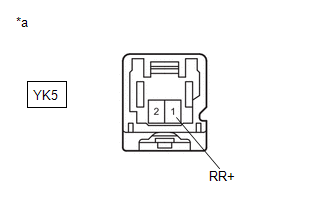

YK5-1 (RR+) - Body ground |

Engine switch off |

Below 1.5 V |

| OK |

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

| NG |

|

|

9. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK5-1 (RR+) - Body ground |

Always |

Below 1.5 V |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

10. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the YK3 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK3-1 (RR+) - Body ground |

Engine switch off |

Below 1.5 V |

| OK |

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

| NG |

|

|

11. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK3 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK3-1 (RR+) - Body ground |

Always |

Below 1.5 V |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

12. |

CHECK HARNESS AND CONNECTOR (SENSOR CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK5-1 (RR+) - YK5-2 (RR-) |

Engine switch on (IG) |

11 to 14 V |

| OK |

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

| NG |

|

|

13. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK5-1 (RR+) - Body ground |

Engine switch on (IG) |

11 to 14 V |

| NG |

|

|

|

14. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK5-2 (RR-) - Body ground |

Always |

Below 1.5 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

15. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK5-2 (RR-) - A28-37 (RR-) |

Always |

Below 1 Ω |

|

YK5-1 (RR+) or A28-22 (RR+) - YK5-2 (RR-) or A28-37 (RR-) |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

16. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK5-1 (RR+) - A28-22 (RR+) |

Always |

Below 1 Ω |

|

YK5-1 (RR+) or A28-22 (RR+) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

17. |

CHECK HARNESS AND CONNECTOR (SENSOR CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the YK3 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK3-1 (RR+) - YK3-2 (RR-) |

Engine switch on (IG) |

11 to 14 V |

| OK |

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

| NG |

|

|

18. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the YK3 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK3-1 (RR+) - Body ground |

Engine switch on (IG) |

11 to 14 V |

| NG |

|

|

|

19. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK3 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK3-2 (RR-) - Body ground |

Always |

Below 1.5 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

20. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK3 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK3-2 (RR-) - A28-37 (RR-) |

Always |

Below 1 Ω |

|

YK3-1 (RR+) or A28-22 (RR+) - YK3-2 (RR-) or A28-37 (RR-) |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

21. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK3 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK3-1 (RR+) - A28-22 (RR+) |

Always |

Below 1 Ω |

|

YK3-1 (RR+) or A28-22 (RR+) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

22. |

CHECK HARNESS AND CONNECTOR (SENSOR CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the Y5 rear speed sensor RH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Turn the engine switch to on (IG).

(e) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Y5-2 (RA+) - Y5-1 (RA-) |

Engine switch on (IG) |

11 to 14 V |

| NG |

|

|

|

23. |

CHECK HARNESS AND CONNECTOR (SENSOR POWER SOURCE CIRCUIT) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the Y5 rear speed sensor RH connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Y5-2 (RA+) - Body ground |

Engine switch off |

Below 1.5 V |

| NG |

|

|

|

24. |

INSPECT NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors. OK: The connector is securely connected. |

|

(b) Disconnect the Y5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(c) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Y5-1 (RA-) or YK5-2 (RR-) - Body ground and other terminals |

Always |

10 kΩ or higher |

| NG |

|

REPLACE NO. 1 PARKING BRAKE WIRE ASSEMBLY |

|

|

25. |

CHECK HARNESS AND CONNECTOR (NO. 1 PARKING BRAKE WIRE ASSEMBLY - BRAKE ACTUATOR ASSEMBLY) |

(a) Make sure that there is no looseness at the locking part and the connecting part of the connectors.

OK:

The connector is securely connected.

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Disconnect the YK5 skid control sensor wire RH (No. 1 parking brake wire assembly) connector.

(d) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

YK5-2 (RR-) or A28-37 (RR-) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2022 MY Avalon [08/2021 - ]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model): C051212; Right Rear Wheel Speed Sensor Circuit Short to Battery](/t3Portal/stylegraphics/info.gif)