| Last Modified: 09-10-2025 | 6.11:8.1.0 | Doc ID: RM100000001RAEM |

| Model Year Start: 2021 | Model: Avalon | Prod Date Range: [08/2020 - ] |

| Title: A25A-FKS (BATTERY / CHARGING): CHARGING SYSTEM: Charging Failure; 2021 - 2022 MY Avalon [08/2020 - ] | ||

|

Charging Failure |

PROCEDURE

PROCEDURE

|

1. |

CHECK GENERATOR PULLEY WITH CLUTCH (ON-VEHICLE INSPECTION) |

(a) Start the engine and visually check that the generator rotor assembly (fan) in the generator assembly is operating.

OK:

The generator rotor assembly (fan) is operating.

| NG |

|

REPLACE GENERATOR PULLEY WITH CLUTCH (ON-VEHICLE INSPECTION) |

|

|

2. |

CHECK GENERATOR PULLEY WITH CLUTCH (UNIT INSPECTION) |

(a) Remove the generator assembly.

(b) Check the installation condition of the generator pulley cap.

OK:

The generator pulley cap is not loose or missing.

(c) Check for forming of particles due to friction (for dry type pulley) or grease leaks (for wet type pulley).

OK:

There are no large amounts of particles (for dry type pulley) or grease leaks (for wet type pulley).

(d) Check the generator pulley with clutch for misalignment (interference with the generator assembly).

OK:

The generator pulley with clutch is not misaligned (no interference with the generator assembly).

|

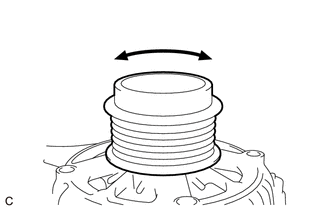

(e) Turn the generator pulley with clutch clockwise and counterclockwise by hand and check for noise. OK: Noise does not occur when turned in either direction. |

|

(f) Turn the generator pulley with clutch clockwise and counterclockwise by hand and visually check for runout.

OK:

The generator pulley with clutch does not have runout.

(g) Inspect generator pulley with clutch.

| OK |

|

| NG |

|

|

|

|

![2021 - 2022 MY Avalon [08/2020 - ]; A25A-FKS (BATTERY / CHARGING): GENERATOR: REMOVAL+](/t3Portal/stylegraphics/info.gif)