- Replacement of direct fuel injector assembly

- Replacement of fuel pump assembly

- Replacement of fuel pressure sensor

- Replacement of throttle body with motor assembly

- Cleaning the deposits from the throttle body with motor assembly

- Replacement of EGR valve assembly

- Gas leak from exhaust system is repaired

| Last Modified: 08-21-2023 | 6.11:8.1.0 | Doc ID: RM100000001PVBI |

| Model Year Start: 2021 | Model: Avalon | Prod Date Range: [08/2020 - ] |

| Title: A25A-FKS (FUEL): FUEL INJECTOR (for Direct Injection): REMOVAL; 2021 - 2022 MY Avalon [08/2020 - ] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during direct fuel injector assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *1: When performing learning using the Techstream. | |||

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Departure Alert System (w/ Steering Control) |

|

|

Pre-collision System |

|||

|

Intelligent Clearance Sonar System*1 |

|||

|

Lighting System (for Gasoline Model with Cornering Light) |

|||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

||

|

Panoramic View Monitor System |

|||

|

|

Inspection after repair |

|

|

CAUTION:

-

Never perform work on fuel system components near any possible ignition sources.

- Vaporized fuel could ignite, resulting in a serious accident.

-

Do not perform work on fuel system components without first disconnecting the cable from the negative (-) battery terminal.

- Sparks could cause vaporized fuel to ignite, resulting in a serious accident.

-

To prevent serious injury due to fuel spray from the high-pressure fuel lines, always discharge fuel system pressure before removing any fuel system components.

NOTICE:

- After the engine switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Audio and Visual System)

- After the engine switch is turned off, the radio and display receiver assembly records various types of memory and settings. As a result, after turning the engine switch off, make sure to wait at least 85 seconds before disconnecting the cable from the negative (-) battery terminal. (for Navigation System)

- This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

PROCEDURE

1. REMOVE FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY

2. REMOVE FUEL DELIVERY PIPE

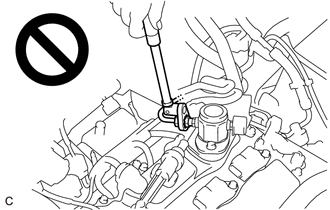

NOTICE:

When replacing the fuel delivery pipe, it is necessary to replace the No. 1 fuel pipe sub-assembly with a new one.

|

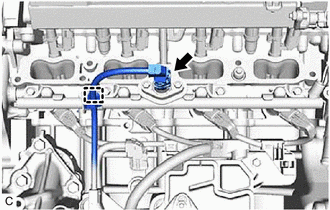

(a) Disconnect the fuel pressure sensor connector. |

|

(b) Disengage the clamp to disconnect the sensor wire from the fuel delivery pipe.

|

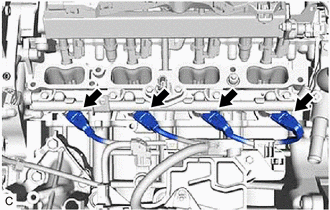

(c) Disconnect the 4 direct fuel injector assembly connectors. NOTICE: Make sure to disconnect the connectors carefully. |

|

|

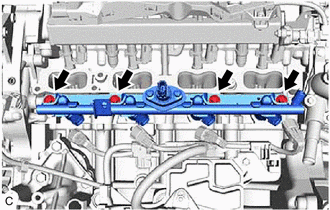

(d) Remove the 4 bolts and fuel delivery pipe with the 4 direct fuel injector assemblies from the cylinder head sub-assembly. NOTICE:

|

|

3. REMOVE DIRECT FUEL INJECTOR ASSEMBLY

|

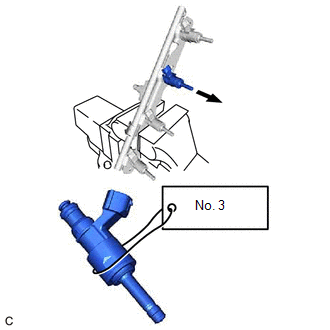

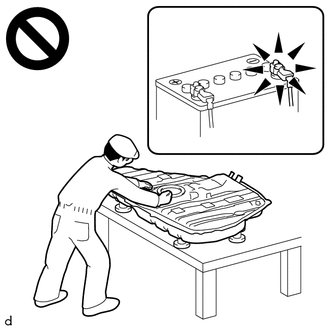

(a) Secure the fuel delivery pipe in a vise between aluminum plates and pull out the 4 direct fuel injector assemblies. NOTICE:

|

|

(b) Remove the nozzle holder clamp from each direct fuel injector assembly.

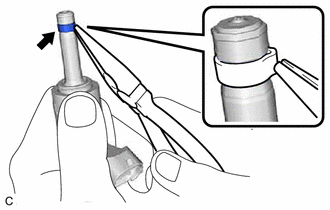

(c) Using needle nose pliers, remove the No. 3 fuel injector back-up ring from each direct fuel injector assembly.

NOTICE:

Do not damage the area that contacts the O-ring.

(d) Remove the O-ring and No. 1 fuel injector back-up ring from each direct fuel injector assembly.

(e) Remove the C-ring and injector vibration insulator from each direct fuel injector assembly.

4. REMOVE FUEL INJECTOR SEAL

|

(a) Using the tip of needle nose pliers, pinch and pull the fuel injector seal at several points to stretch it. NOTICE:

|

|

(b) Remove the fuel injector seal from each direct fuel injector assembly.

|

|

|

![2019 - 2022 MY Avalon [04/2018 - ]; PARK ASSIST / MONITORING: INTELLIGENT CLEARANCE SONAR SYSTEM (for Gasoline Model): CALIBRATION](/t3Portal/stylegraphics/info.gif)