- Shift position: P

- A/C: Off

- Engine warmed up

- Engine Speed: 3000 rpm

- Injection Mode: Direct

| Last Modified: 08-21-2023 | 6.11:8.1.0 | Doc ID: RM100000001B4MX |

| Model Year Start: 2019 | Model: Avalon | Prod Date Range: [04/2018 - ] |

| Title: 2GR-FKS (FUEL): FUEL SYSTEM: ON-VEHICLE INSPECTION; 2019 - 2022 MY Avalon [04/2018 - ] | ||

ON-VEHICLE INSPECTION

PROCEDURE

1. CHECK FUEL PUMP OPERATION AND INSPECT FOR FUEL LEAK

(a) Check fuel pump operation.

(1) Connect the Techstream to the DLC3.

(2) Turn the engine switch on (IG).

NOTICE:

Do not start the engine.

(3) Turn the Techstream on.

(4) Enter the following menus: Powertrain / Engine / Active Test / Activate the Circuit Relay.

Powertrain > Engine > Active Test

|

Tester Display |

|---|

|

Activate the Circuit Relay |

(5) Check for pressure in the fuel tube sub-assembly from the fuel line. Check that sounds of fuel flowing from the fuel tank assembly can be heard. If no sounds can be heard, check the relay, fuel pump, ECM and wiring connectors.

(b) Inspect for fuel leaks.

(1) Check that there are no fuel leaks from the fuel system after doing any maintenance or repairs. If there is a fuel leak, repair or replace parts as necessary.

(c) Turn the engine switch off.

(d) Disconnect the Techstream from the DLC3.

2. CHECK FUEL PRESSURE

(a) Discharge fuel system pressure.

(b) Measure the battery voltage.

Standard Voltage:

11 to 14 V

(c) Disconnect the cable from the negative (-) battery terminal.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

|

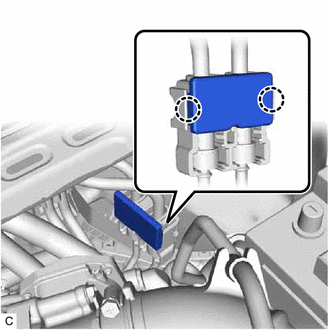

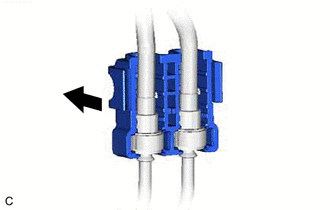

(d) Disengage the 2 claws to remove the No. 2 fuel pipe clamp. |

|

|

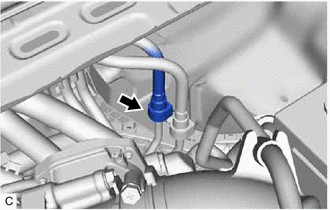

(e) Remove the No. 1 fuel pipe clamp from the fuel tube connector. |

|

|

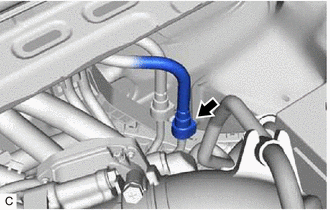

(f) Disconnect the No. 2 fuel tube sub-assembly (for Direct Injection). (1) Disconnect the No. 2 fuel tube sub-assembly from the fuel pipe. |

|

|

(g) Disconnect the fuel tube sub-assembly (for Port Injection). (1) Disconnect the fuel tube sub-assembly from the fuel pipe. |

|

|

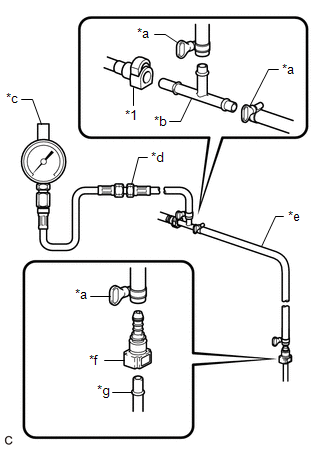

(h) Install SST (EFI fuel pressure gauge) as shown in the illustration. SST: 09268-45101 09268-41250 09268-41260 09268-41280 09268-41500 09268-41700 95336-08070 |

|

(i) Wipe up any spilled fuel.

(j) Connect the cable to the negative (-) battery terminal.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

(k) Connect the Techstream to the DLC3.

(l) Turn the engine switch on (IG).

NOTICE:

Do not start the engine.

(m) Turn the Techstream on.

(n) Enter the following menus: Powertrain / Engine / Active Test / Activate the Circuit Relay.

Powertrain > Engine > Active Test

|

Tester Display |

|---|

|

Activate the Circuit Relay |

(o) Measure the fuel pressure.

Standard Fuel Pressure:

196 to 833 kPa (2.0 to 8.5 kgf/cm2, 28 to 121 psi)

- If the fuel pressure is less than the standard, check the fuel hoses and their connections, fuel pump, fuel filter and fuel main valve assembly.

- If the result is not as specified, replace the fuel main valve assembly.

(p) Disconnect the Techstream from the DLC3.

(q) Start the engine.

(r) Measure the fuel pressure at idle.

Standard Fuel Pressure:

196 to 833 kPa (2.0 to 8.5 kgf/cm2, 28 to 121 psi)

HINT:

Refer to Standard Idle Speed.

(s) Stop the engine.

(t) Check that the fuel pressure remains as specified for 5 minutes.

Standard Fuel Pressure:

98 kPa (1.0 kgf/cm2, 14.2 psi) or more

If the result is not as specified, check the fuel pump, fuel main valve assembly and/or fuel injector assemblies.

(u) After checking the fuel pressure, disconnect the cable from the negative (-) battery terminal and carefully remove SST to prevent fuel from spraying.

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

(v) Connect the fuel tube sub-assembly (for Port Injection).

(1) Connect the fuel tube sub-assembly to the fuel pipe.

(w) Connect the No. 2 fuel tube sub-assembly (for Direct Injection).

(1) Connect the No. 2 fuel tube sub-assembly to the fuel pipe.

(x) Install the No. 1 fuel pipe clamp to the fuel tube connector.

(y) Engage the 2 claws to install the No. 2 fuel pipe clamp.

(z) Inspect for fuel leaks.

3. CHECK FUEL PRESSURE (for High Pressure)

(a) Connect the Techstream to the DLC3.

(b) Turn the engine switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Powertrain / Engine / Data List / Engine Speed, Coolant Temperature, Fuel Pressure (High) and Injection Mode.

Powertrain > Engine > Data List

|

Tester Display |

|---|

|

Engine Speed |

|

Coolant Temperature |

|

Fuel Pressure (High) |

|

Injection Mode |

(e) Start the engine and warm it up until the engine coolant temperature is 75°C (167°F) or higher with all the accessories switched off.

(f) According to the display on the Techstream, read the Data List.

Standard:

|

Techstream Display |

Condition |

Specified Condition |

|---|---|---|

|

Fuel Pressure (High) |

|

2400 to 19500 kPag |

If the result is not as specified, check the fuel pump, fuel pump assembly, fuel pressure sensor (fuel delivery pipe with sensor assembly LH) (for High Pressure) and wire harnesses.

(g) Stop the engine.

|

|

|

![2019 - 2022 MY Avalon [04/2018 - ]; 2GR-FKS (FUEL): FUEL SYSTEM: PRECAUTION](/t3Portal/stylegraphics/info.gif)