| Last Modified: 08-21-2023 | 6.11:8.1.0 | Doc ID: RM100000001AZ8L |

| Model Year Start: 2019 | Model: Avalon | Prod Date Range: [04/2018 - 08/2020] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model): C1417; IG1 Voltage Supply too High; 2019 - 2020 MY Avalon [04/2018 - 08/2020] | ||

|

DTC |

C1417 |

IG1 Voltage Supply too High |

DESCRIPTION

If a malfunction is detected in the power supply circuit, the skid control ECU (brake actuator assembly) stores this DTC and the fail-safe function prohibits ABS operation.

This DTC is stored when the +BS terminal voltage deviates due to a malfunction in a power supply or charging system circuit such as the battery or alternator circuit, etc.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

|---|---|---|---|

|

C1417 |

IG1 Voltage Supply too High |

+BS terminal voltage is more than 16.5 V for 1 second or more. |

|

WIRING DIAGRAM

Refer to DTC C1241.

CAUTION / NOTICE / HINT

NOTICE:

PROCEDURE

|

1. |

CHECK BATTERY |

(a) Check the battery voltage.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Positive (+) terminal - Negative (-) terminal |

Engine switch off |

11 to 14 V |

| NG |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE TERMINAL) |

|

(a) Make sure that there is no looseness at the locking part and the connecting part of the connector. OK: The connector is securely connected. |

|

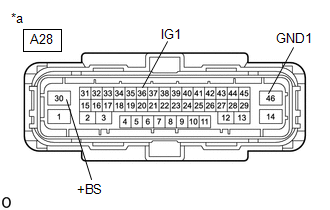

(b) Disconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Check both the connector case and the terminals for deformation and corrosion.

OK:

No deformation or corrosion.

(d) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A28-30 (+BS) - Body ground |

Always |

11 to 14 V |

|

A28-30 (+BS) - A28-46 (GND1) |

Always |

11 to 14 V |

|

A28-36 (IG1) - Body ground |

Engine switch on (IG) |

11 to 14 V |

|

A28-36 (IG1) - A28-46 (GND1) |

Engine switch on (IG) |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (POWER SOURCE CIRCUIT) |

|

|

3. |

RECONFIRM DTC |

(a) Turn the engine switch off.

(b) Reconnect the A28 skid control ECU (brake actuator assembly) connector.

(c) Clear the DTCs.

Chassis > ABS/VSC/TRAC/EPB > Clear DTCs

(d) Turn the engine switch off.

(e) Start the engine.

(f) Perform a road test.

(g) Check if the same DTC is output.

Chassis > ABS/VSC/TRAC/EPB > Trouble Codes

|

Result |

Proceed to |

|---|---|

|

C1417 is not output |

A |

|

C1417 is output |

B |

| A |

|

| B |

|

|

|

|

![2019 - 2020 MY Avalon [04/2018 - 08/2020]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for Gasoline Model): C1241; Low or High Power Supply Voltage](/t3Portal/stylegraphics/info.gif)