- DTC judgment completed

- System normal

| Last Modified: 09-10-2025 | 6.11:8.1.0 | Doc ID: RM100000001ARN7 |

| Model Year Start: 2019 | Model: Avalon | Prod Date Range: [04/2018 - ] |

| Title: UA80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: P074011; Torque Converter Clutch Circuit Short to Ground; 2019 - 2022 MY Avalon [04/2018 - ] | ||

|

DTC |

P074011 |

Torque Converter Clutch Circuit Short to Ground |

DESCRIPTION

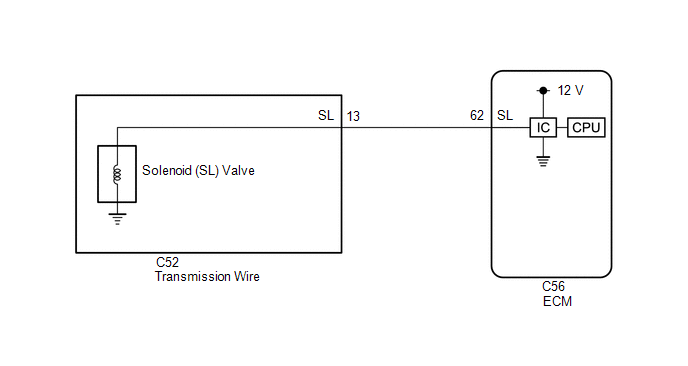

Solenoid (SL) valve is turned on and off by signals from the ECM to control the hydraulic pressure acting on the lock-up relay valve, which then controls operation of the lock-up clutch.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

Note |

|---|---|---|---|---|---|---|

|

P074011 |

Torque Converter Clutch Circuit Short to Ground |

While the vehicle is being driven so that lock-up is not requested, a short to ground is detected in the solenoid (SL) valve circuit (2-trip detection logic). |

|

Comes on |

DTC stored |

SAE Code: P2769 |

Fail-safe function:

If the ECM detects a malfunction, it turns Solenoid (SL) valve off.

MONITOR DESCRIPTION

Based on the signals from the throttle position sensor, the air flow meter and the crankshaft position sensor, the ECM sends a signal to solenoid (SL) valve to regulate the hydraulic pressure and provide smoother torque converter engagement. Solenoid (SL) valve responds to commands from the ECM. The valve controls the lock-up relay valve to perform the torque-converter lock-up function. If the ECM detects a short to ground in the solenoid (SL) valve circuit, it will illuminate the MIL and store the DTC.

MONITOR STRATEGY

|

Related DTCs |

P2769: Solenoid (SL) valve/Range check |

|

Required sensors/components |

Solenoid (SL) valve |

|

Frequency of operation |

Continuous |

|

Duration |

1 time |

|

MIL operation |

2 driving cycles |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

|

The monitor will run whenever the following DTCs are not stored |

None |

|

Battery voltage |

8 V or more |

|

Engine switch |

On (IG) |

|

Starter |

OFF |

TYPICAL MALFUNCTION THRESHOLDS

|

All of the following conditions are met |

0.065536 sec. or more |

|

Time after command to solenoid OFF to ON |

0.008192 sec. or more |

|

Command to solenoid |

ON |

|

Solenoid terminal voltage level |

Low |

COMPONENT OPERATING RANGE

|

Solenoid (SL) valve |

Resistance: 11 to 15 Ω at 20°C (68°F) |

CONFIRMATION DRIVING PATTERN

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

- Connect the Techstream to the DLC3.

- Turn the engine switch on (IG) and turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the engine switch off and wait for 2 minutes or more.

- Turn the engine switch on (IG) and turn the Techstream on.

- Start the engine.

-

Perform the Lock-up Function inspection in Road Test. [*1]

HINT:

[*1] : Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Stop the vehicle.

- Enter the following menus: Powertrain / Transmission / Utility / All Readiness.

- Input the DTC: P074011.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

PROCEDURE

PROCEDURE

|

1. |

INSPECT TRANSMISSION WIRE (SOLENOID (SL) VALVE) |

|

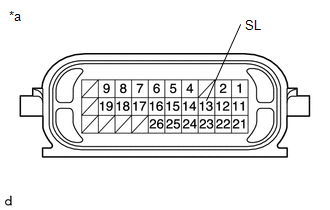

(a) Disconnect the C52 transmission wire connector. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

13 (SL) - Body ground |

20°C (68°F) |

11 to 15 Ω |

(c) Connect the C52 transmission wire connector.

| NG |

|

|

|

2. |

CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM) |

(a) Disconnect the C56 ECM connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C56-62 (SL) - Body ground |

20°C (68°F) |

11 to 15 Ω |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR (TRANSMISSION WIRE - ECM) |

|

|

3. |

REPLACE ECM |

(a) Replace the ECM.

| NEXT |

|

|

4. |

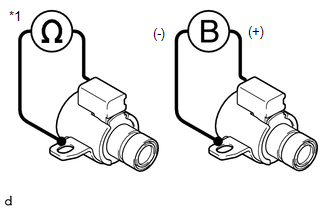

INSPECT SOLENOID (SL) VALVE |

|

(a) Remove the solenoid (SL) valve. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

Solenoid (SL) valve connector terminal - Solenoid (SL) valve body |

20°C (68°F) |

11 to 15 Ω |

(c) Connect a positive (+) lead from the battery to the terminal of the solenoid valve connector, and a negative (-) lead to the solenoid body. Check that the valve moves and makes an operating sound.

OK:

Valve moves and makes an operating sound.

| OK |

|

| NG |

|

|

|

|

![2019 - 2022 MY Avalon [04/2018 - ]; UA80E (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)