| Last Modified: 08-21-2023 | 6.11:8.1.0 | Doc ID: RM100000001AOD1 |

| Model Year Start: 2019 | Model: Avalon HV | Prod Date Range: [04/2018 - ] |

| Title: A25A-FXS (ENGINE MECHANICAL): ENGINE ASSEMBLY: INSTALLATION; 2019 - 2022 MY Avalon HV [04/2018 - ] | ||

INSTALLATION

CAUTION / NOTICE / HINT

CAUTION:

- The engine assembly with transaxle is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop or the engine assembly with transaxle may fall off the engine lifter.

- To prevent burns, do not touch the engine, exhaust manifold or other high temperature components while the engine is hot.

PROCEDURE

1. INSTALL ENGINE MOUNTING INSULATOR LH

HINT:

Perform this procedure only when replacement of the engine mounting insulator LH is necessary.

|

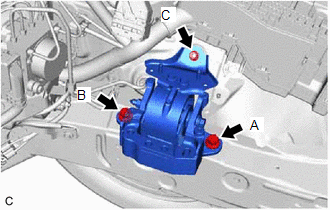

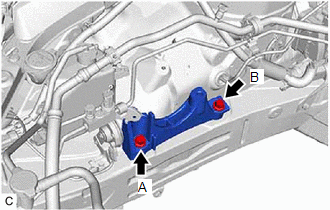

(a) Install the engine mounting insulator LH with the 2 bolts and nut. Torque: 72 N·m {734 kgf·cm, 53 ft·lbf} NOTICE: Temporarily tighten the bolt (A), and then fully tighten the 2 bolts and nut in the order of (B), (A) and (C). |

|

2. INSTALL ENGINE MOUNTING SPACER

HINT:

Perform this procedure only when replacement of the engine mounting spacer is necessary.

|

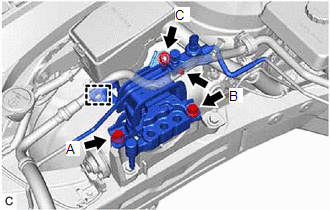

(a) Install the engine mounting spacer to the vehicle body with the 2 bolts. Torque: 72 N·m {734 kgf·cm, 53 ft·lbf} NOTICE: Temporarily tighten the bolt (A), and then fully tighten the 2 bolts in the order of (B) and (A). |

|

3. INSTALL ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

HINT:

Perform this procedure only when replacement of the engine mounting insulator sub-assembly RH is necessary.

|

(a) Install the engine mounting insulator sub-assembly RH with the 2 bolts and nut. Torque: 72 N·m {734 kgf·cm, 53 ft·lbf} NOTICE: Temporarily tighten the bolt (A), and then fully tighten the 2 bolts and nut in the order of (B), (A) and (C). |

|

(b) Connect the cooler bracket to the engine mounting insulator sub-assembly RH with the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

(c) Engage the clamp.

(d) Install the radiator reserve tank assembly with the bolt and nut.

Torque:

5.0 N·m {51 kgf·cm, 44 in·lbf}

(e) Engage the No. 6 water by-pass hose.

4. INSTALL ENGINE HANGERS

5. REMOVE ENGINE ASSEMBLY FROM ENGINE STAND

(a) Remove the engine assembly from the engine stand.

6. INSTALL NO. 1 CRANKSHAFT POSITION SENSOR PLATE

7. INSTALL FLYWHEEL SUB-ASSEMBLY

8. INSTALL TRANSMISSION INPUT DAMPER ASSEMBLY

9. INSTALL HYBRID VEHICLE TRANSAXLE ASSEMBLY

10. INSTALL FLYWHEEL HOUSING SIDE COVER

11. INSTALL STARTER HOLE INSULATOR

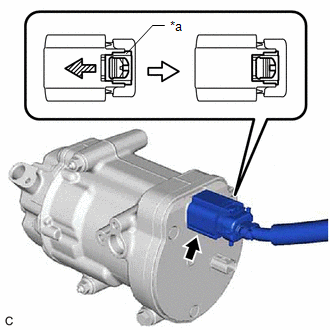

12. INSTALL HV AIR CONDITIONING WIRE

(a) Engage the guide to install the HV air conditioning wire to the hybrid vehicle transaxle assembly.

(b) Install the bolt.

Torque:

20 N·m {204 kgf·cm, 15 ft·lbf}

(c) Connect the connector and slide the green-colored lock as shown in the illustration to lock it securely.

CAUTION:

Make sure to wear insulated gloves.

NOTICE:

Make sure that the connector is connected securely.

|

*a |

Green-colored Lock |

|

Slide |

(d) Engage the 2 clamps.

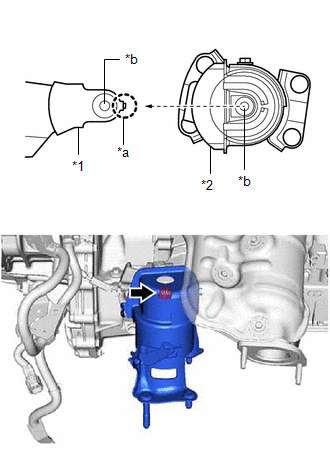

13. INSTALL REAR ENGINE MOUNTING INSULATOR

HINT:

Perform this procedure only when replacement of the rear engine mounting insulator is necessary.

|

(a) Align the hole of the rear engine mounting insulator with the protrusion of the rear engine mounting bracket, slide the rear engine mounting insulator onto the rear engine mounting bracket to align the holes and install the rear engine mounting insulator with the bolt. Torque: 72 N·m {734 kgf·cm, 53 ft·lbf} |

|

14. INSTALL FRONT ENGINE MOUNTING INSULATOR

HINT:

Perform this procedure only when replacement of the front engine mounting insulator is necessary.

15. INSTALL FRONT FRAME ASSEMBLY

16. INSTALL ENGINE WIRE

(a) Connect all connectors and clamps, and install the engine wire to the engine assembly with transaxle.

17. INSTALL STEERING GEAR HEAT INSULATOR

18. INSTALL FLYWHEEL HOUSING UNDER COVER

(a) Install the flywheel housing under cover to the cylinder block sub-assembly.

19. INSTALL ENGINE ASSEMBLY WITH TRANSAXLE

HINT:

Perform inspection after repair after replacing the engine assembly.

(a) Set the engine assembly with transaxle on an engine lifter.

NOTICE:

- Using height adjustment attachments and plate lift attachments, keep the engine assembly with transaxle level.

- Do not perform any procedures while the engine assembly is suspended because doing so may cause the engine assembly to drop, resulting in injury. However, the engine assembly needs to be suspended when it is installed to or removed from an engine stand.

(b) Remove the 4 bolts, No. 1 engine hanger and No. 2 engine hanger from the cylinder head sub-assembly and engine mounting bracket RH.

(c) Install the fuel delivery guard to the engine mounting bracket RH with the bolt.

Torque:

40 N·m {408 kgf·cm, 30 ft·lbf}

(d) Operate the engine lifter and install the engine assembly with transaxle to the vehicle.

CAUTION:

Do not raise the engine assembly with transaxle more than necessary. If the engine is raised excessively, the vehicle may also be lifted up.

NOTICE:

- Make sure that the engine assembly with transaxle is clear of all wiring and hoses.

- While raising the engine assembly with transaxle into the vehicle, do not allow it to contact the vehicle.

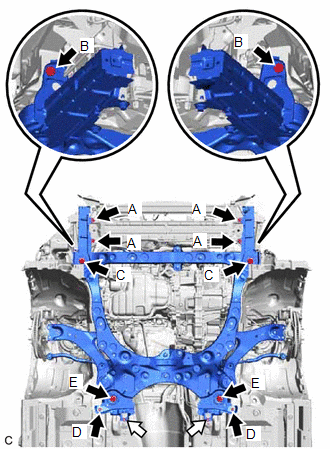

(e) Install the front bumper extension sub-assembly RH and front bumper extension sub-assembly LH to the front frame assembly and vehicle body with the 8 bolts.

|

Bolt |

|

Nut |

Torque:

Bolt (A) :

9.0 N·m {92 kgf·cm, 80 in·lbf}

Bolt (B) :

12.5 N·m {127 kgf·cm, 9 ft·lbf}

Bolt (C) :

135 N·m {1377 kgf·cm, 100 ft·lbf}

(f) Install the front suspension member bracket sub-assembly RH and front suspension member bracket sub-assembly LH to the front frame assembly and vehicle body with the 4 bolts and 2 nuts.

Torque:

Bolt (D) :

17.5 N·m {178 kgf·cm, 13 ft·lbf}

Bolt (E) :

135 N·m {1377 kgf·cm, 100 ft·lbf}

Nut :

17.5 N·m {178 kgf·cm, 13 ft·lbf}

|

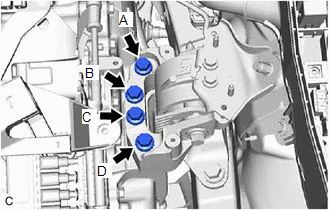

(g) Install the engine mounting insulator LH to the hybrid vehicle transaxle assembly with the 4 bolts. Torque: 42 N·m {428 kgf·cm, 31 ft·lbf} NOTICE: Fully tighten the 4 bolts in the order of (A), (C), (B) and (D). |

|

|

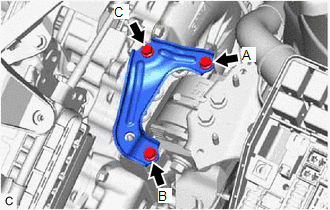

(h) Install the engine mounting stay LH to the engine mounting insulator LH with the 3 bolts. Torque: 8.0 N·m {82 kgf·cm, 71 in·lbf} NOTICE: Temporarily tighten the bolt (A), and then fully tighten the 3 bolts in the order of (B), (C) and (A). |

|

(i) Install the engine mounting insulator sub-assembly RH to the engine mounting bracket RH with the 3 bolts and nut.

Torque:

Bolt :

72 N·m {734 kgf·cm, 53 ft·lbf}

Nut :

42 N·m {428 kgf·cm, 31 ft·lbf}

(j) Install the body mounting plate with the 6 bolts.

Torque:

17.5 N·m {178 kgf·cm, 13 ft·lbf}

20. INSTALL FRONT DRIVE SHAFT ASSEMBLY

21. INSTALL FRONT EXHAUST PIPE ASSEMBLY (TWC: Rear Catalyst)

22. CONNECT STEERING INTERMEDIATE SHAFT ASSEMBLY

23. CONNECT NO. 5 WATER BY-PASS HOSE

(a) Connect the No. 5 water by-pass hose to the No. 3 water by-pass pipe and slide the clip to secure it.

24. CONNECT WIRE HARNESS

(a) Engage the earth wire with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(b) Engage the claw to connect the wire harness to the engine room relay block and junction block assembly.

(c) Connect the 5 connectors to the engine room relay block and junction block assembly.

(d) Install the nut to the engine room relay block and junction block assembly.

Torque:

8.0 N·m {82 kgf·cm, 71 in·lbf}

(e) Install the No. 2 relay block cover to the engine room relay block and junction block assembly.

25. CONNECT NO. 5 INVERTER COOLING HOSE

(a) Connect the No. 5 inverter cooling hose to the motor cooling cooler and slide the clip to secure it.

26. CONNECT SUCTION HOSE SUB-ASSEMBLY

27. CONNECT NO. 1 COOLER REFRIGERANT DISCHARGE HOSE SUB-ASSEMBLY

28. CONNECT NO. 2 RADIATOR HOSE

(a) Connect the No. 2 radiator hose to the water inlet and slide the clip to secure it.

29. CONNECT NO. 1 RADIATOR HOSE

(a) Connect the No. 1 radiator hose to the front engine mounting bracket with the bolt.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

(b) Connect the No. 1 radiator hose to the water outlet and slide the clip to secure it.

30. INSTALL NO. 2 ENGINE COOLANT TEMPERATURE SENSOR

31. CONNECT FUEL TUBE SUB-ASSEMBLY

(a) Connect the fuel tube sub-assembly.

(1) Connect the fuel tube sub-assembly to the fuel pipe.

(b) Install the No. 1 fuel pipe clamp to the fuel tube connector.

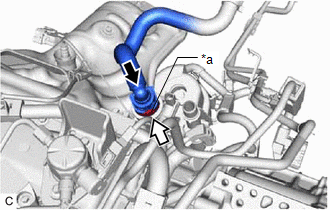

32. CONNECT INLET HEATER HOSE

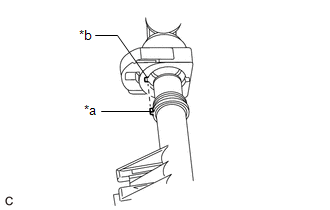

|

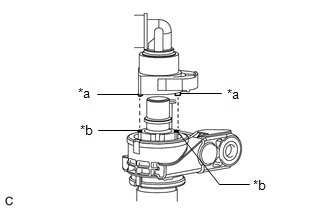

(a) Align the protrusions of the inlet heater hose connector with the cutouts in the flow shutting valve (water by-pass hose assembly) and push them together until the inlet heater hose connector makes a "click" sound. |

|

(b) Push in the retainer.

|

*a |

Retainer |

|

Push |

|

Push in |

(c) Check that the flow shutting valve (water by-pass hose assembly) and inlet heater hose connector are securely connected by pulling on them.

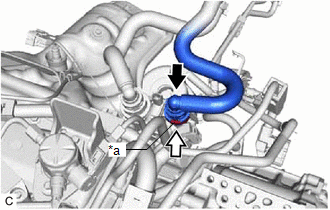

33. CONNECT OUTLET HEATER HOSE

|

(a) Align the protrusion of the No. 2 water by-pass pipe sub-assembly with the cutout in the outlet heater hose connector and push them together until the outlet heater hose makes a "click" sound. |

|

(b) Push in the retainer.

|

*a |

Retainer |

|

Push |

|

Push in |

(c) Check that the No. 2 water by-pass pipe sub-assembly and outlet heater hose connector are securely connected by pulling on them.

34. CONNECT NO. 1 FUEL VAPOR FEED HOSE

(a) Connect the No. 1 fuel vapor feed hose to the No. 1 vacuum switching valve assembly and slide the clip to secure it.

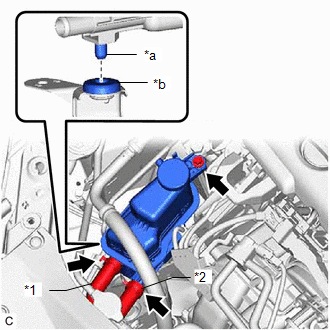

35. INSTALL INVERTER RESERVE TANK ASSEMBLY

|

(a) Connect the No. 2 inverter cooling hose to the inverter reserve tank assembly and slide the clip to secure it. |

|

(b) Connect the No. 5 inverter cooling hose to the inverter reserve tank assembly and slide the clip to secure it.

(c) Fit the pin of the inverter reserve tank assembly into grommet as shown in the illustration.

(d) Install the inverter reserve tank assembly with the bolt.

Torque:

5.0 N·m {51 kgf·cm, 44 in·lbf}

36. INSTALL INVERTER WITH CONVERTER ASSEMBLY

37. INSTALL FRONT LOWER BUMPER ABSORBER

(a) Engage the 2 claws to install the front lower bumper absorber.

(b) Install the 4 bolts.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

38. INSTALL HEADLIGHT ASSEMBLY

39. INSTALL FRONT FENDER APRON SEAL LH

(a) Install the front fender apron seal LH with the 2 screws and clip.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

40. INSTALL FRONT FENDER APRON SEAL RH

(a) Install the front fender apron seal RH with the 2 screws and clip.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

41. INSTALL NO. 2 ENGINE UNDER COVER ASSEMBLY

(a) Install the No. 2 engine under cover assembly with the 4 screws and 6 clips.

Torque:

7.5 N·m {76 kgf·cm, 66 in·lbf}

42. INSTALL NO. 1 ENGINE UNDER COVER

(a) Install the No. 1 engine under cover with the bolt, 6 screws and 2 clips.

Torque:

Bolt :

7.5 N·m {76 kgf·cm, 66 in·lbf}

43. INSTALL FRONT WHEEL OPENING EXTENSION PAD LH

(a) Install the front wheel opening extension pad LH with the 3 screws.

44. INSTALL FRONT WHEEL OPENING EXTENSION PAD RH

(a) Install the front wheel opening extension pad RH with the 3 screws.

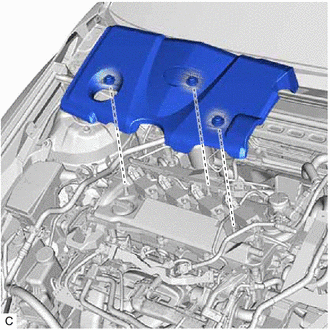

45. INSTALL NO. 1 ENGINE COVER SUB-ASSEMBLY

|

(a) Engage the 3 clips to install the No. 1 engine cover sub-assembly. NOTICE:

|

|

46. ADD ENGINE OIL

47. ADD HYBRID TRANSAXLE FLUID

48. ADD ENGINE COOLANT (for Engine)

49. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

50. WARM UP COMPRESSOR

51. INSPECT SHIFT LEVER POSITION

52. ADJUST SHIFT LEVER POSITION

53. INSPECT FOR ENGINE OIL LEAK

54. INSPECT FOR COOLANT LEAK (for Engine)

55. INSPECT FOR REFRIGERANT LEAK

56. INSPECT FOR FUEL LEAK

57. INSPECT FOR EXHAUST GAS LEAK

58. CHECK ENGINE OIL LEVEL

59. INSPECT HYBRID TRANSAXLE FLUID

60. INSPECT ENGINE COOLANT LEVEL IN RESERVOIR TANK

61. INSTALL FRONT WHEELS

62. ALIGN FRONT WHEELS FACING STRAIGHT AHEAD

63. INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

64. PERFORM INITIALIZATION

65. INSPECT IGNITION TIMING

66. INSPECT ENGINE IDLE SPEED

67. INSPECT CO/HC

68. CHECK SPEED SENSOR SIGNAL

|

|

|

![2019 - 2021 MY Avalon HV [04/2018 - 08/2021]; A25A-FXS (ENGINE MECHANICAL): ENGINE ASSEMBLY: REMOVAL+](/t3Portal/stylegraphics/info.gif)