| Last Modified: 09-10-2025 | 6.11:8.1.0 | Doc ID: RM100000001ANK0 |

| Model Year Start: 2019 | Model: Avalon HV | Prod Date Range: [04/2018 - ] |

| Title: BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for HV Model): C1211,C1212,C1225,C1226; SLA Linear Solenoid; 2019 - 2022 MY Avalon HV [04/2018 - ] | ||

|

DTC |

C1211 |

SLA Linear Solenoid |

|

DTC |

C1212 |

SLR Linear Solenoid |

|

DTC |

C1225 |

SA1 Solenoid Circuit |

|

DTC |

C1226 |

SA2 Solenoid Circuit |

DESCRIPTION

The linear solenoids SLA and SLR control the regulator based on signals from the skid control ECU (brake booster with master cylinder assembly) and produce servo pressure in accordance with the vehicle condition.

When the system is normal, the switching solenoid SGH is opened to allow brake fluid to flow to the stroke simulator when the brake pedal is depressed. When the system is abnormal, the switching solenoid SGH closes to prevent the flow of brake fluid.

When the system is normal, the switching solenoid SSA is closed. When the system is abnormal, the switching solenoid SSA is opened to allow fluid to flow to the brake master cylinder reservoir assembly.

HINT:

- If the supply voltage decreases, a drop in current may cause DTCs to be stored.

- DTC C1225 indicates a malfunction related to solenoid SSA, and DTC C1226 indicates a malfunction related to solenoid SGH.

|

DTC No. |

Detection Item |

INF Code |

DTC Detection Condition |

Trouble Area |

MIL |

Note |

|---|---|---|---|---|---|---|

|

C1211 |

SLA Linear Solenoid |

21 22 23 24 25 26 |

|

|

Comes on |

|

|

C1212 |

SLR Linear Solenoid |

31 32 33 34 35 36 |

|

|

Comes on |

|

|

C1225 |

SA1 Solenoid Circuit |

41 42 43 44 45 46 |

|

|

Comes on |

|

|

C1226 |

SA2 Solenoid Circuit |

71 72 73 74 75 76 |

|

|

Comes on |

|

MONITOR DESCRIPTION

The skid control ECU (brake booster with master cylinder assembly) monitors the drive voltage and current of the linear solenoids (SLA, SLR, SSA and SGH). Based on the monitored information, if any of the following abnormal conditions are detected, the MIL is illuminated and a DTC is stored.

- A malfunction of the current monitor is detected.

- Based on the duty cycle, the monitored current value is considerably low.

- An open circuit is detected.

- Based on the duty cycle, the monitored current value is considerably high.

- A current leakage is detected.

- When the monitored current value increases to a value that is not possible when normal.

MONITOR STRATEGY

|

Related DTCs |

C13C1: Linear solenoid range/performance C13C2 (Case 1): Linear solenoid circuit low C13C2 (Case 2): Linear solenoid circuit low C13C2 (Case 3): Linear solenoid circuit low C13C3 (Case 1): Linear solenoid circuit high C13C3 (Case 2): Linear solenoid circuit high C13C3 (Case 3): Linear solenoid circuit high C13C3 (Case 4): Linear solenoid circuit high C13CA: Linear solenoid range/performance C13CB (Case 1): Linear solenoid circuit low C13CB (Case 2): Linear solenoid circuit low C13CB (Case 3): Linear solenoid circuit low C13CC (Case 1): Linear solenoid circuit high C13CC (Case 2): Linear solenoid circuit high C13CC (Case 3): Linear solenoid circuit high C13CC (Case 4): Linear solenoid circuit high C14F2: Linear solenoid range/performance C14F3 (Case 1): Linear solenoid circuit low C14F3 (Case 2): Linear solenoid circuit low C14F3 (Case 3): Linear solenoid circuit low C14F4 (Case 1): Linear solenoid circuit high C14F4 (Case 2): Linear solenoid circuit high C14F4 (Case 3): Linear solenoid circuit high C14F4 (Case 4): Linear solenoid circuit high C14FB: Linear solenoid range/performance C14FC (Case 1): Linear solenoid circuit low C14FC (Case 2): Linear solenoid circuit low C14FC (Case 3): Linear solenoid circuit low C14FD (Case 1): Linear solenoid circuit high C14FD (Case 2): Linear solenoid circuit high C14FD (Case 3): Linear solenoid circuit high C14FD (Case 4): Linear solenoid circuit high |

|

Required Sensors/Components(Main) |

Skid control ECU (brake booster with master cylinder assembly) Brake actuator (brake booster with master cylinder assembly) |

|

Required Sensors/Components(Related) |

Skid control ECU (brake booster with master cylinder assembly) Brake actuator (brake booster with master cylinder assembly) |

|

Frequency of Operation |

Continuous |

|

Duration |

0.054 seconds: C13C1, C13C2 (Case 2), C13C2 (Case 3), C13C3 (Case 2), C13C3 (Case 3), C13C3 (Case 4), C13CA, C13CB (Case 2), C13CB (Case 3), C13CC (Case 2), C13CC (Case 3), C13CC (Case 4), C14F2, C14F3 (Case 2), C14F3 (Case 3), C14F4 (Case 2), C14F4 (Case 3), C14F4 (Case 4), C14FB, C14FC (Case 2), C14FC (Case 3), C14FD (Case 2), C14FD (Case 3) and C14FD (Case 4) 7 times: C14F3 (Case 1), C14F4 (Case 1), C14FC (Case 1) and C14FD (Case 1) 14 times: C13C2 (Case 1), C13C3 (Case 1), C13CB (Case 1) and C13CC (Case 1) |

|

MIL Operation |

Immediately |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

C13C1, C13CA, C14F2 and C14FB

|

Monitor runs whenever the following DTCs are not stored |

None |

|

Both of the following conditions are met |

- |

|

Serial communication with high side IC |

Valid |

|

Solenoid low side operating |

On |

C13C2, C13CB, C14F3 and C14FC (Case 1)

|

Monitor runs whenever the following DTCs are not stored |

None |

|

All of the following conditions are met |

- |

|

Power supply for linear solenoid |

Higher than 9.13 V |

|

Command to main relay |

On |

|

Main relay |

On |

|

Serial communication with high side IC |

Valid |

|

Solenoid low side operating |

On |

|

Current |

Less than 2.3 A |

|

Difference in present target current and previous target current |

0.2 A or less |

|

Output duty cycle |

Higher than 0% |

|

Difference in present power supply voltage for linear solenoid and previous power supply voltage for linear solenoid |

1 V or less |

|

Solenoid current correction coefficient learning |

Complete |

|

Current monitor |

Normal |

C13C2, C13CB, C14F3 and C14FC (Case 2)

|

Monitor runs whenever the following DTCs are not stored |

None |

|

All of the following conditions are met |

A, B, C, D, E, F, G, H, I and J |

|

A. Power supply for linear solenoid |

Higher than 9.13 V |

|

B. Command to main relay |

On |

|

C. Main relay |

On |

|

D. Serial communication with high side IC |

Valid |

|

E. Solenoid low side operating |

On |

|

F. Current |

Less than 2.3 A |

|

G. Difference in present target current and previous target current |

0.2 A or less |

|

H. Output duty cycle |

Higher than 0% |

|

I. Current monitor |

Normal |

|

J. Either of the following conditions is met |

- |

|

Difference in present power supply voltage for linear solenoid and previous power supply voltage for linear solenoid |

Higher than 1 V |

|

Solenoid current correction coefficient learning |

Not complete |

C13C2, C13CB, C14F3 and C14FC (Case 3)

|

Monitor runs whenever the following DTCs are not stored |

None |

|

All of the following conditions are met |

- |

|

Command to main relay |

On |

|

Main relay |

On |

|

Solenoid low side operating |

On |

|

Serial communication with high side IC |

Valid |

|

Output duty cycle |

0% |

|

Current monitor |

Normal |

|

Current |

Less than 0.2 A |

C13C3, C13CC, C14F4 and C14FD (Case 1)

|

Monitor runs whenever the following DTCs are not stored |

None |

|

All of the following conditions are met |

- |

|

Power supply for linear solenoid |

Less than 16 V |

|

Serial communication with high side IC |

Valid |

|

Solenoid low side operating |

On |

|

Difference in present target current and previous target current |

0.2 A or less |

|

Difference in present power supply voltage for linear solenoid and previous power supply voltage for linear solenoid |

1 V or less |

|

Solenoid current correction coefficient learning |

Complete |

|

Current monitor |

Normal |

C13C3, C13CC, C14F4 and C14FD (Case 2)

|

Monitor runs whenever the following DTCs are not stored |

None |

|

All of the following conditions are met |

A, B, C, D, E and F |

|

A. Power supply for linear solenoid |

Less than 16 V |

|

B. Serial communication with high side IC |

Valid |

|

C. Solenoid low side operating |

On |

|

D. Difference in present target current and previous target current |

0.2 A or less |

|

E. Current monitor |

Normal |

|

F. Either of the following conditions is met |

- |

|

Difference in present power supply voltage for linear solenoid and previous power supply voltage for linear solenoid |

Higher than 1 V |

|

Solenoid current correction coefficient learning |

Not complete |

C13C3, C13CC, C14F4 and C14FD (Case 3)

|

Monitor runs whenever the following DTCs are not stored |

None |

|

All of the following conditions are met |

- |

|

Solenoid low side operating |

On |

|

Output duty cycle |

0% |

|

Current monitor |

Normal |

C13C3, C13CC, C14F4 and C14FD (Case 4)

|

Monitor runs whenever the following DTCs are not stored |

None |

|

Both of the following conditions are met |

- |

|

Serial communication with high side IC |

Valid |

|

Current monitor power supply |

Higher than 1.09 V, and less than 1.24 V |

TYPICAL MALFUNCTION THRESHOLDS

C13C1 and C13CA

|

One of the following conditions is met |

A, B, C, D or E |

|

A. Difference in monitor current (for solenoid control) and monitor current (for monitoring) |

Higher than 0.281 A |

|

B. Both of the following conditions are met |

- |

|

Current monitor value (for solenoid control) |

33 or less |

|

Current |

Less than 2.3 A |

|

C. Both of the following conditions are met |

- |

|

Current monitor value (for monitoring) |

33 or less |

|

Current |

Less than 2.3 A |

|

D. Reference voltage for current monitor circuit |

1.24 V or more, or 1.09 V or less |

|

E. AC/DC converter built into CPU standard voltage |

4.4 V or less |

C14F2 and C14FB

|

One of the following conditions is met |

A, B, C, D or E |

|

A. Difference in monitor current (for solenoid control) and monitor current (for monitoring) |

Higher than 0.294 A |

|

B. Both of the following conditions are met |

- |

|

Current monitor value (for solenoid control) |

33 or less |

|

Current |

Less than 2.3 A |

|

C. Both of the following conditions are met |

- |

|

Current monitor value (for monitoring) |

33 or less |

|

Current |

Less than 2.3 A |

|

D. Reference voltage for current monitor circuit |

1.24 V or more, or 1.09 V or less |

|

E. AC/DC converter built into CPU standard voltage |

4.4 V or less |

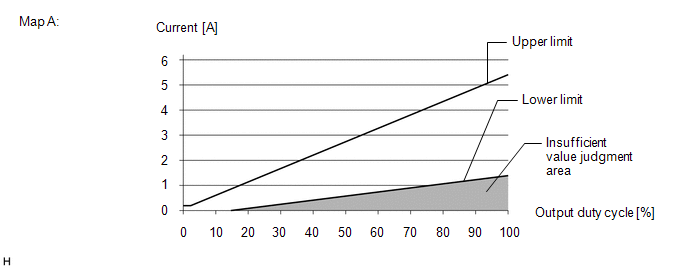

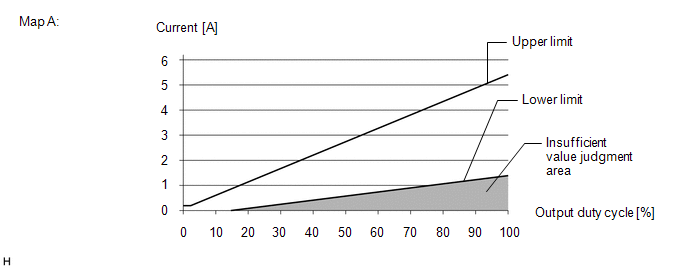

C13C2, C13CB, C14F3 and C14FC (Case 1)

|

Solenoid current to output duty cycle relationship |

Within the insufficient value judgment area in the following Map A |

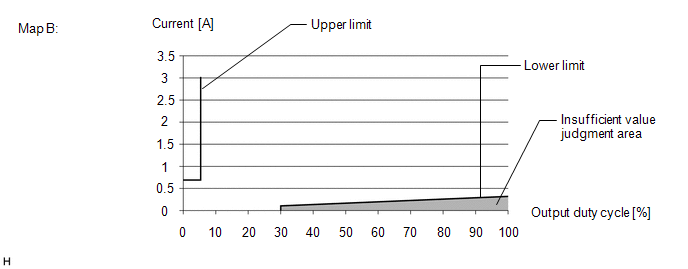

C13C2, C13CB, C14F3 and C14FC (Case 2)

|

Solenoid current to output duty cycle relationship |

Within the insufficient value judgment area in the following Map B |

C13C2, C13CB, C14F3 and C14FC (Case 3)

|

Solenoid high side voltage |

Higher than 5.46 V |

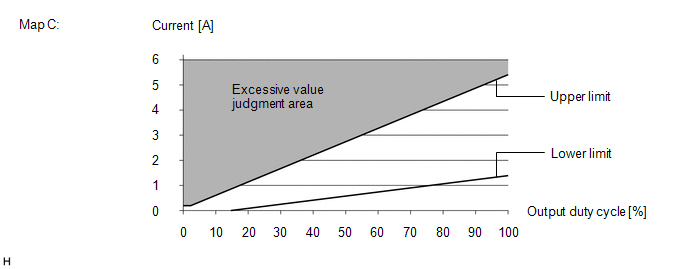

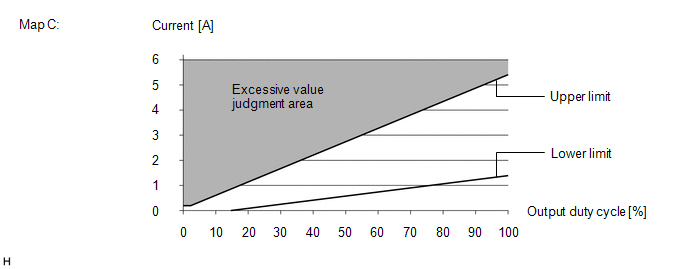

C13C3, C13CC, C14F4 and C14FD (Case 1)

|

Solenoid current to output duty cycle relationship |

Within the excessive value judgment area in the following Map C |

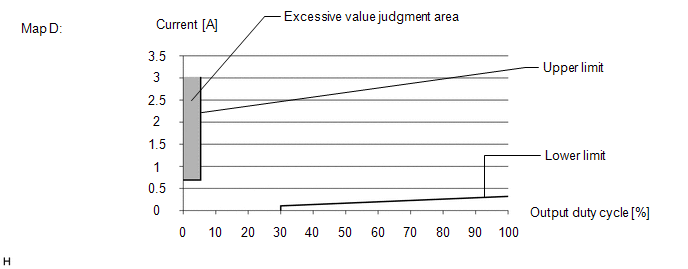

C13C3, C13CC, C14F4 and C14FD (Case 2)

|

Solenoid current to output duty cycle relationship |

Within the excessive value judgment area in the following Map D |

C13C3, C13CC, C14F4 and C14FD (Case 3)

|

Current |

0.15 A or more |

C13C3, C13CC, C14F4 and C14FD (Case 4)

|

Current |

Higher than 2.3 A |

COMPONENT OPERATING RANGE

C13C1 and C13CA

|

All of the following conditions are met |

- |

|

Output duty cycle |

Higher than 0% |

|

Difference in monitor current (for solenoid control) and monitor current (for monitoring) |

Less than 0.281 A |

|

Current monitor value (for solenoid control) |

More than 33 |

|

Current monitor value (for monitoring) |

More than 33 |

|

Current |

Less than 2.3 A |

|

Reference voltage for current monitor circuit |

Less than 1.24 V, and higher than 1.09 V |

|

AC/DC converter built into CPU standard voltage |

Higher than 4.4 V |

C14F2 and C14FB

|

All of the following conditions are met |

- |

|

Serial communication with high side IC |

Valid |

|

Solenoid low side operating |

On |

|

Difference in monitor current (for solenoid control) and monitor current (for monitoring) |

0.294 A or less |

|

Current monitor value (for solenoid control) |

More than 33 |

|

Current monitor value (for monitoring) |

More than 33 |

|

Current |

Less than 2.3 A |

|

Reference voltage for current monitor circuit |

Less than 1.24 V, and higher than 1.09 V |

|

AC/DC converter built into CPU standard voltage |

Higher than 4.4 V |

C13C2, C13CB, C14F3 and C14FC (Case 1 and 2)

|

All of the following conditions are met |

- |

|

Power supply for linear solenoid |

Higher than 9.13 V |

|

Command to main relay |

On |

|

Main relay |

On |

|

Serial communication with high side IC |

Valid |

|

Solenoid low side operating |

On |

|

Current |

Less than 2.3 A |

|

Difference in present target current and previous target current |

0.2 A or less |

|

Output duty cycle |

Higher than 0% |

|

Current monitor |

Normal |

|

Solenoid current to output duty cycle relationship |

Current is not below lower limit (Outside of the insufficient value judgment area in the following Map A) |

C13C2, C13CB, C14F3 and C14FC (Case 3)

|

All of the following conditions are met |

- |

|

Main relay |

On |

|

Solenoid low side operating |

On |

|

Serial communication with high side IC |

Valid |

|

Output duty cycle |

0% |

|

High side IC malfunction |

Not detected |

|

Solenoid high side voltage |

5.46 V or less |

C13C3, C13CC, C14F4 and C14FD (Case 1 and 2)

|

All of the following conditions are met |

- |

|

Power supply for linear solenoid |

Less than 16 V |

|

Serial communication with high side IC |

Valid |

|

Solenoid low side operating |

On |

|

Difference in present target current and previous target current |

0.2 A or less |

|

Current monitor |

Normal |

|

Output duty cycle |

Higher than 0% |

|

Solenoid current to output duty cycle relationship |

Current is not above upper limit (Outside of the excessive value judgment area in the following Map C) |

C13C3, C13CC, C14F4 and C14FD (Case 3)

|

All of the following conditions are met |

- |

|

Main relay |

On |

|

Solenoid low side operating |

On |

|

Output duty cycle |

0% |

|

Current monitor |

Normal |

|

Current |

Less than 0.15 A |

C13C3, C13CC, C14F4 and C14FD (Case 4)

|

All of the following conditions are met |

- |

|

Main relay |

On |

|

Solenoid low side operating |

On |

|

Serial communication with high side IC |

Valid |

|

Output duty cycle |

Higher than 0% |

|

Current |

Less than 2.3 A |

CONFIRMATION DRIVING PATTERN

- Connect the Techstream to the DLC3.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the power switch off.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Depress the brake pedal 1 or more times.

- Enter the following menus: Chassis / ABS/VSC/TRAC / Trouble Codes.

-

Read the DTCs.

HINT:

- If a DTC is output, the system is malfunctioning.

- If a DTC is not output, perform the following procedure.

-

If the DTCs are not output, perform a universal trip and check for permanent DTCs.

HINT:

- If a permanent DTC is output, the system is malfunctioning.

- If no permanent DTCs are output, the system is normal.

CAUTION / NOTICE / HINT

NOTICE:

After replacing the skid control ECU (brake booster with master cylinder assembly), perform linear solenoid valve offset learning, ABS holding solenoid valve learning, yaw rate and acceleration sensor zero point calibration and system information memorization after performing "Reset Memory".

PROCEDURE

PROCEDURE

|

1. |

CHECK DTC |

(a) Clear the DTCs.

Chassis > ABS/VSC/TRAC > Clear DTCs

(b) Turn the power switch off.

(c) Turn the power switch on (IG).

(d) Check if the same DTC is output.

Chassis > ABS/VSC/TRAC > Trouble Codes

HINT:

If a DTC for undervoltage is output, first troubleshoot the power source system.

|

Result |

Proceed to |

|---|---|

|

DTCs C1211, C1212, C1225 and C1226 are not output. |

A |

|

A DTC related to low voltage is output. |

B |

|

DTCs C1211, C1212, C1225 and/or C1226 are output. |

C |

| A |

|

| B |

|

REPAIR CIRCUITS INDICATED BY OUTPUT DTCS |

| C |

|

REPLACE BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY |

|

|

|

![2019 - 2022 MY Avalon HV [04/2018 - ]; BRAKE CONTROL / DYNAMIC CONTROL SYSTEMS: ELECTRONICALLY CONTROLLED BRAKE SYSTEM (for HV Model): DTC CHECK / CLEAR](/t3Portal/stylegraphics/info.gif)