- DTCs are stored

- Slight vibration at a vehicle speed of 5 km/h (3 mph) or less

- Shock or vibration during acceleration

| Last Modified: 02-14-2025 | 6.11:8.1.0 | Doc ID: RM100000001T4LN |

| Model Year Start: 2021 | Model: Camry HV | Prod Date Range: [10/2020 - ] |

| Title: A25A-FXS (FUEL): FUEL INJECTOR (for Port Injection): REMOVAL; 2021 - 2024 MY Camry HV [10/2020 - ] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization or registration) that must be performed after parts are removed and installed, or replaced during port fuel injector assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

Auxiliary battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision System |

|||

|

Lighting System (w/ AFS)(EXT) |

|||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

||

|

Panoramic View Monitor System |

|||

|

Replacement of inverter with converter assembly |

Resolver learning |

|

|

|

Replacement of ECM |

Perform Vehicle Identification Number (VIN) registration |

MIL illuminates |

|

|

Inspection after repair |

|

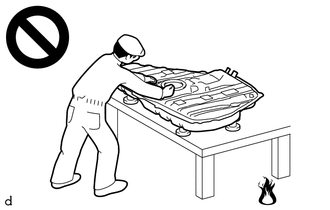

CAUTION:

-

Never perform work on fuel system components near any possible ignition sources.

- Vaporized fuel could ignite, resulting in a serious accident.

-

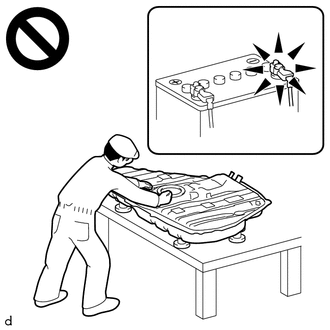

Do not perform work on fuel system components without first disconnecting the cable from the negative (-) auxiliary battery terminal.

- Sparks could cause vaporized fuel to ignite, resulting in a serious accident.

-

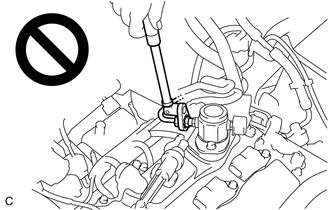

To prevent serious injury due to fuel spray from the high-pressure fuel lines, always discharge fuel system pressure before removing any fuel system components.

NOTICE:

This procedure includes the removal of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

PROCEDURE

1. PRECAUTION

NOTICE:

After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work.

2. DISCHARGE FUEL SYSTEM PRESSURE

3. REMOVE LUGGAGE TRIM SERVICE HOLE COVER

4. DISCONNECT CABLE FROM NEGATIVE AUXILIARY BATTERY TERMINAL

NOTICE:

When disconnecting the cable, some systems need to be initialized after the cable is reconnected.

5. REMOVE THROTTLE BODY WITH MOTOR ASSEMBLY

6. REMOVE EGR VALVE ASSEMBLY

7. REMOVE NO. 2 WATER BY-PASS PIPE

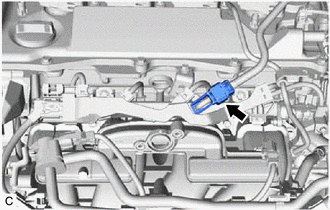

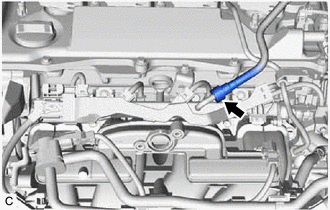

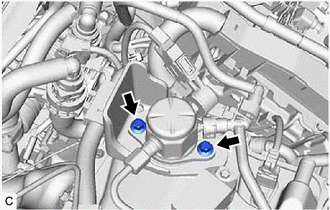

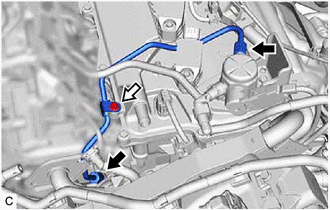

8. DISCONNECT FUEL TUBE SUB-ASSEMBLY

|

(a) Remove the fuel pipe clamp from the fuel tube connector. |

|

|

(b) Disconnect the fuel tube sub-assembly from the fuel delivery pipe with sensor assembly. |

|

9. REMOVE NO. 1 FUEL PIPE SUB-ASSEMBLY

CAUTION:

To prevent serious injury due to fuel spray from the high-pressure fuel lines, always discharge fuel system pressure before removing any fuel system components.

|

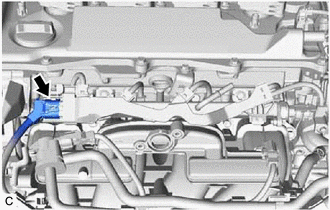

(a) Disconnect the ignition coil connector. |

|

(b) for EGR Valve Bracket Connection Type:

|

(1) Using a 17 mm union nut wrench, loosen the 2 union nuts of the No. 1 fuel pipe sub-assembly. |

|

(c) for Cylinder Head Cover Sub-assembly Connection Type:

(1) Using a 17 mm union nut wrench, loosen the 2 union nuts of the No. 1 fuel pipe sub-assembly.

|

Union Nut |

|

Bolt |

(2) Using an 8 mm socket wrench, remove the bolt.

|

(d) Loosen the 2 bolts of the fuel pump assembly. |

|

(e) Remove the No. 1 fuel pipe sub-assembly from the fuel delivery pipe and fuel pump assembly.

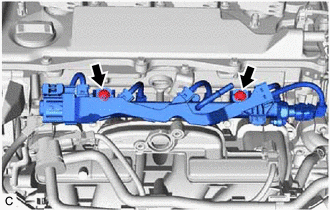

10. REMOVE FUEL DELIVERY PIPE WITH SENSOR ASSEMBLY

|

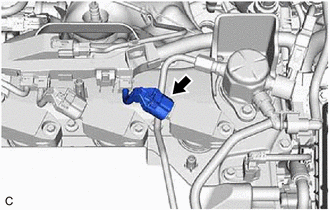

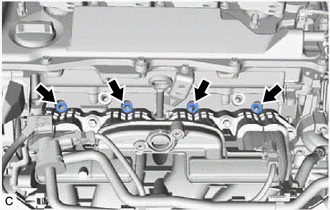

(a) Disconnect the No. 5 engine wire connector. |

|

|

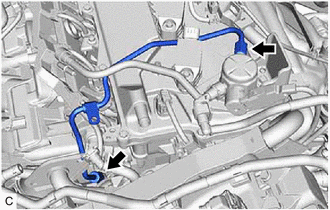

(b) Remove the 2 bolts and fuel delivery pipe with sensor assembly with the 4 port fuel injector assemblies from the cylinder head sub-assembly. NOTICE:

|

|

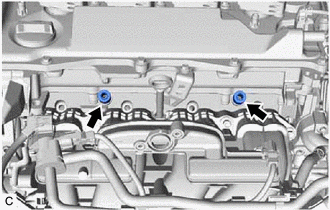

11. REMOVE NO. 1 DELIVERY PIPE SPACER

|

(a) Remove the 2 No. 1 delivery pipe spacers from the cylinder head sub-assembly. |

|

12. REMOVE INJECTOR VIBRATION INSULATOR

|

(a) Remove the 4 injector vibration insulators from the cylinder head sub-assembly. |

|

13. REMOVE NO. 5 ENGINE WIRE

|

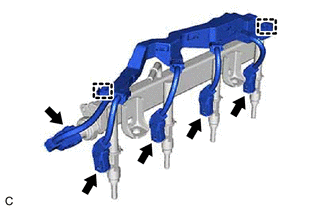

(a) Disconnect the 4 port fuel injector assembly connectors and fuel pressure sensor connector. |

|

(b) Disengage the 2 clamps to remove the No. 5 engine wire from the fuel delivery pipe with sensor assembly.

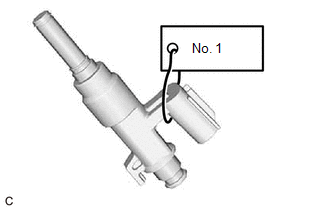

14. REMOVE PORT FUEL INJECTOR ASSEMBLY

|

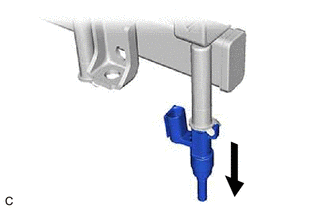

(a) Pull the 4 port fuel injector assemblies out of the fuel delivery pipe with sensor assembly. |

|

|

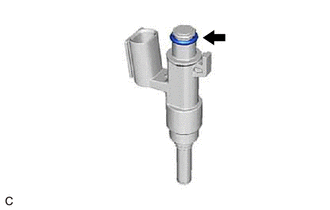

(b) Remove the O-ring from each port fuel injector assembly. |

|

|

(c) Attach a tag or label with the corresponding cylinder number to each port fuel injector assembly so that they can be installed to their original locations. NOTICE: Cover the port fuel injector assemblies with plastic bags to prevent damage and contamination. |

|

|

|

|

![2021 - 2024 MY Camry HV [10/2020 - ]; PRE-COLLISION: PRE-COLLISION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)