- Cooling effectiveness is poor

- Cooling response is slow

| Last Modified: 02-14-2025 | 6.11:8.1.0 | Doc ID: RM100000001R418 |

| Model Year Start: 2021 | Model: Camry HV | Prod Date Range: [10/2020 - ] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING SYSTEM: Cooling is Poor; 2021 - 2024 MY Camry HV [10/2020 - ] | ||

|

Cooling is Poor |

DESCRIPTION

If the cooling effect of the air conditioning system is weak, the following factors may be the cause.

|

Symptom |

Factor |

|---|---|

|

|

|

WIRING DIAGRAM

PROCEDURE

|

1. |

CHECK ECO MODE CONTROL OPERATION |

(a) Check that ECO mode control is disabled (ECO mode indicator is not illuminated).

(b) Operate the ECO switch assembly (electric parking brake switch assembly) and check that the ECO mode indicator illuminates and the blower speed is reduced.

HINT:

-

When ECO mode control is operating, the air conditioning amplifier assembly controls the air conditioning system to enhance fuel efficiency. Therefore, explain to the customer that, when ECO mode control is operating, the blower speed will be reduced.

Control

Outline

Blower Control

When the air conditioning system is in AUTO mode, the blower speed will be reduced to a certain speed. Additionally, if warm-up control is operating, the blower speed will be further reduced.

Air Inlet Control

If the ambient temperature is a certain value or more, the air inlet mode will be changed to recirculation mode.

- In some situations, ECO mode control may not operate even though it is enabled.

(c) Operate the ECO switch assembly (electric parking brake switch assembly) and check that the ECO mode indicator turns off and the blower speed returns to normal.

OK:

When the ECO switch assembly (electric parking brake switch assembly) is operated, ECO mode control is enabled/disabled and the blower speed is controlled.

| NG |

|

|

|

2. |

PERFORM REFRIGERANT SHORTAGE CHECK |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Utility / Refrigerant Gas Volume Check.

Body Electrical > Air Conditioner > Utility

|

Tester Display |

|---|

|

Refrigerant Gas Volume Check |

(e) Check that the following conditions are met and perform the refrigerant shortage check according to the display on the Techstream.

Measurement Condition:

|

Item |

Condition |

|---|---|

|

A/C switch |

On |

|

Ambient temperature* |

0 to 49°C (32 to 120°F) |

|

Blower speed |

HI |

*: If the ambient temperature is not within the range shown, do not perform this check.

|

Result |

Amount of Refrigerant |

|---|---|

|

Refrigerant correct |

Correct |

|

Refrigerant shortage |

Insufficient |

OK:

"Refrigerant correct" is displayed on the Techstream.

| NG |

|

|

|

3. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Air Mix Servo Targ Pulse(D) |

No. 1 air conditioning radiator damper servo sub-assembly (driver side air mix) pulse |

Min.: 128 Max.: 383 |

Operates between 165 and 257 pulses |

|

Air Mix Servo Targ Pulse(P) |

No. 1 air conditioning radiator damper servo sub-assembly (front passenger side air mix) pulse |

Min.: 128 Max.: 383 |

Operates between 255 and 347 pulses |

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

Air Mix Servo Targ Pulse(D) |

Body Electrical > Air Conditioner > Active Test

|

Tester Display |

|---|

|

Air Mix Servo Targ Pulse(P) |

OK:

Each damper servo motor operates.

| NG |

|

GO TO DTC TROUBLESHOOTING PROCEDURE FOR MALFUNCTIONING DAMPER SERVO MOTOR

|

|

|

4. |

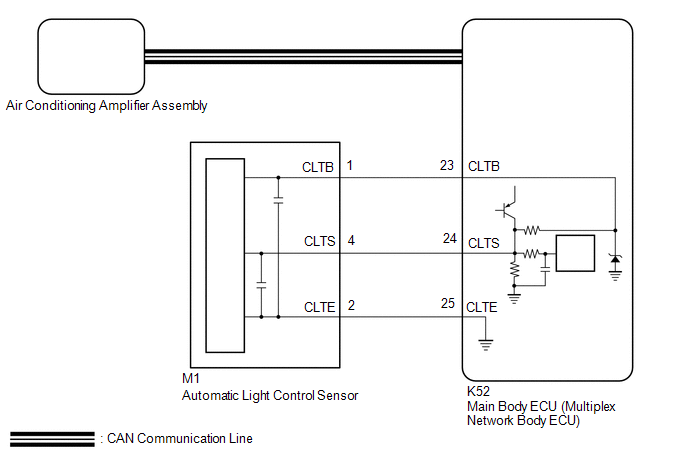

INSPECT WIRE HARNESS AND CONNECTOR (AUTOMATIC LIGHT CONTROL SENSOR - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

(a) Disconnect the M1 automatic light control sensor connector.

(b) Disconnect the K52 main body ECU (multiplex network body ECU) connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

M1-1 (CLTB) - K52-23 (CLTB) |

Always |

Below 1 Ω |

|

M1-2 (CLTE) - K52-25 (CLTE) |

Always |

Below 1 Ω |

|

M1-4 (CLTS) - K52-24 (CLTS) |

Always |

Below 1 Ω |

|

M1-1 (CLTB) or K52-23 (CLTB) - Other terminals and body ground |

Always |

10 kΩ or higher |

|

M1-2 (CLTE) or K52-25 (CLTE) - Other terminals and body ground |

Always |

10 kΩ or higher |

|

M1-4 (CLTS) or K52-24 (CLTS) - Other terminals and body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

5. |

INSPECT AUTOMATIC LIGHT CONTROL SENSOR |

(a) Remove the automatic light control sensor.

(b) Inspect the automatic light control sensor.

| OK |

|

| NG |

|

|

|

|

![2021 - 2022 MY Camry HV [10/2020 - 08/2022]; HEATING / AIR CONDITIONING: AIR CONDITIONING SYSTEM: DIAGNOSTIC TROUBLE CODE CHART](/t3Portal/stylegraphics/info.gif)