- DTC judgment completed

- System normal

| Last Modified: 02-14-2025 | 6.11:8.1.0 | Doc ID: RM100000001EAOW |

| Model Year Start: 2019 | Model: Camry HV | Prod Date Range: [09/2018 - ] |

| Title: A25A-FXS (ENGINE CONTROL): SFI SYSTEM: P034031; Camshaft Position Sensor "A" Bank 1 or Single Sensor No Signal; 2019 - 2024 MY Camry HV [09/2018 - ] | ||

|

DTC |

P034031 |

Camshaft Position Sensor "A" Bank 1 or Single Sensor No Signal |

DESCRIPTION

Refer to DTC P034011.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

Note |

|---|---|---|---|---|---|---|

|

P034031 |

Camshaft Position Sensor "A" Bank 1 or Single Sensor No Signal |

No camshaft position sensor (for intake camshaft) signal for 5 seconds at an engine speed of 600 rpm or higher (1 trip detection logic). |

|

Comes on |

DTC stored |

|

Reference: Inspection using an oscilloscope.

MONITOR DESCRIPTION

If no pulse signal is transmitted by the camshaft position sensor (for intake camshaft) despite the camshaft rotating, the ECM interprets this as a malfunction of the sensor.

MONITOR STRATEGY

|

Related DTCs |

P0340: Camshaft position sensor verify pulse input |

|

Required Sensors/Components (Main) |

Camshaft position sensor (for intake camshaft) |

|

Required Sensors/Components (Related) |

Crankshaft position sensor |

|

Frequency of Operation |

Continuous |

|

Duration |

5 seconds |

|

MIL Operation |

Immediate |

|

Sequence of Operation |

None |

TYPICAL ENABLING CONDITIONS

|

All of the following conditions are met |

- |

|

Auxiliary battery voltage |

8 V or higher |

|

Power switch |

On (IG) |

|

Camshaft position sensor voltage |

0.3 to 4.7 V |

|

Engine speed |

600 rpm or higher |

|

Camshaft position sensor range check fail (P0342, P0343) |

Not detected |

|

Hybrid control module judge |

Engine running |

|

Lost communication with hybrid vehicle control ECU assembly (U0293) |

Not detected |

TYPICAL MALFUNCTION THRESHOLDS

|

Camshaft position sensor signal |

No signal |

CONFIRMATION DRIVING PATTERN

HINT:

- Connect the Techstream to the DLC3.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the power switch off and wait for at least 30 seconds.

- Turn the power switch on (IG).

- Turn the Techstream on.

- Put the engine in Inspection Mode (Maintenance Mode).

- Start the engine [A].

- Idle the engine for 10 seconds or more [B].

- Enter the following menus: Powertrain / Engine / Trouble Codes [C].

-

Read the pending DTCs.

HINT:

- If a pending DTC is output, the system is malfunctioning.

- If a pending DTC is not output, perform the following procedure.

- Enter the following menus: Powertrain / Engine / Utility / All Readiness.

- Input the DTC: P034031.

-

Check the DTC judgment result.

Techstream Display

Description

NORMAL

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

HINT:

- If the judgment result is NORMAL, the system is normal.

- If the judgment result is ABNORMAL, the system is malfunctioning.

- If the judgment result is INCOMPLETE, perform steps [B] through [C] again.

-

[A] to [C]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- When clearing the permanent DTCs, do not disconnect the cable from the auxiliary battery terminal or attempt to clear the DTCs during this procedure, as doing so will clear the universal trip and normal judgment histories.

WIRING DIAGRAM

Refer to DTC P034011.

CAUTION / NOTICE / HINT

NOTICE:

-

Vehicle Control History may be stored in the hybrid vehicle control ECU assembly if the engine is malfunctioning. Certain vehicle condition information is recorded when Vehicle Control History is stored. Reading the vehicle conditions recorded in both the freeze frame data and Vehicle Control History can be useful for troubleshooting.

for NICKEL METAL HYDRIDE BATTERY:

for LITHIUM-ION BATTERY:

(Select Powertrain in Health Check and then check the time stamp data.)

-

If any "Engine Malfunction" Vehicle Control History item has been stored in the hybrid vehicle control ECU assembly, make sure to clear it. However, as all Vehicle Control History items are cleared simultaneously, if any Vehicle Control History items other than "Engine Malfunction" are stored, make sure to perform any troubleshooting for them before clearing Vehicle Control History.

for NICKEL METAL HYDRIDE BATTERY:

for LITHIUM-ION BATTERY:

HINT:

- If no problem is found through this diagnostic troubleshooting procedure, there may be a mechanical problem with the engine.

- Read Freeze Frame Data using the Techstream. The ECM records vehicle and driving condition information as Freeze Frame Data the moment a DTC is stored. When troubleshooting, Freeze Frame Data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

|

1. |

CHECK HARNESS AND CONNECTOR |

|

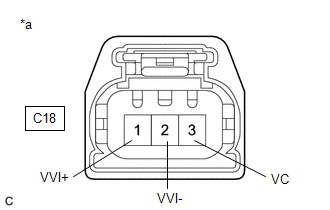

*a |

Front view of wire harness connector (to Camshaft Position Sensor (for Intake Camshaft)) |

HINT:

Make sure that the connector is properly connected. If it is not, securely connect it and check for DTCs again.

(a) Disconnect the camshaft position sensor (for intake camshaft) connector.

(b) Turn the power switch on (IG).

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C18-3 (VC) - Body ground |

Power switch on (IG) |

4.5 to 5.5 V |

|

C18-1 (VVI+) - Body ground |

Power switch on (IG) |

3.0 to 5.0 V |

(d) Turn the power switch off and wait for at least 30 seconds.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C18-3 (VC) - C18-1 (VVI+) |

Power switch off |

1.425 to 1.575 kΩ |

|

C18-2 (VVI-) - Body ground |

Always |

Below 1 Ω |

| NG |

|

|

|

2. |

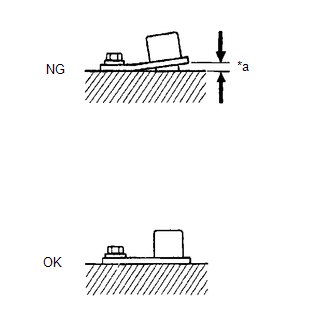

CHECK SENSOR INSTALLATION AND CONDUCT VISUAL INSPECTION (CAMSHAFT POSITION SENSOR (FOR INTAKE CAMSHAFT)) |

|

*a |

Clearance |

(a) Visually check the camshaft position sensor (for intake camshaft) for damage.

(b) Check the camshaft position sensor (for intake camshaft) installation condition.

OK:

The camshaft position sensor (for intake camshaft) does not have any damage and is installed properly.

| NG |

|

SECURELY REINSTALL CAMSHAFT POSITION SENSOR (FOR INTAKE CAMSHAFT) |

|

|

3. |

INSPECT INTAKE CAMSHAFT (TIMING ROTOR) |

(a) Check the timing rotor of the intake camshaft.

OK:

Camshaft timing rotor does not have any cracks or deformation.

HINT:

Perform "Inspection After Repair" after replacing the intake camshaft.

| OK |

|

| NG |

|

|

4. |

CHECK HARNESS AND CONNECTOR (CAMSHAFT POSITION SENSOR (FOR INTAKE CAMSHAFT) - ECM) |

(a) Disconnect the camshaft position sensor (for intake camshaft) connector.

(b) Disconnect the ECM connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C18-1 (VVI+) - C100-90 (VV1+) |

Always |

Below 1 Ω |

|

C18-2 (VVI-) - C100-89 (VV1-) |

Always |

Below 1 Ω |

|

C18-3 (VC) - C100-88 (VCV1) |

Always |

Below 1 Ω |

|

C18-1 (VVI+) or C100-90 (VV1+) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C18-2 (VVI-) or C100-89 (VV1-) - Body ground and other terminals |

Always |

10 kΩ or higher |

|

C18-3 (VC) or C100-88 (VCV1) - Body ground and other terminals |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2019 - 2024 MY Camry HV [09/2018 - ]; A25A-FXS (ENGINE CONTROL): SFI SYSTEM: P034011,P034015; Camshaft Position Sensor "A" Bank 1 or Single Sensor Circuit Short to Ground+](/t3Portal/stylegraphics/info.gif)