| Last Modified: 02-14-2025 | 6.11:8.1.0 | Doc ID: RM1000000015G1B |

| Model Year Start: 2018 | Model: Camry HV | Prod Date Range: [07/2017 - 09/2018] |

| Title: BRAKE SYSTEM (OTHER): BRAKE SYSTEM: ON-VEHICLE INSPECTION; 2018 MY Camry HV [07/2017 - 09/2018] | ||

ON-VEHICLE INSPECTION

CAUTION / NOTICE / HINT

NOTICE:

DTCs may be stored during the inspection procedure. Be sure to clear the DTCs and check that no DTCs are output after the inspection is finished.

PROCEDURE

1. INSPECT PRESSURE SENSOR

(a) Check auxiliary battery voltage.

Standard Voltage:

11 to 14 V (while the power switch is off)

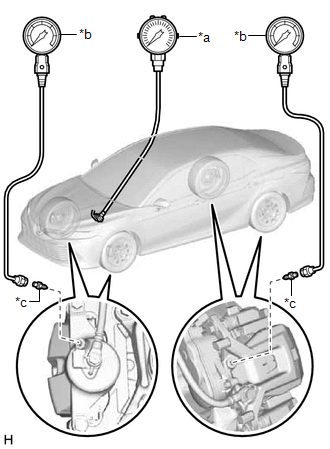

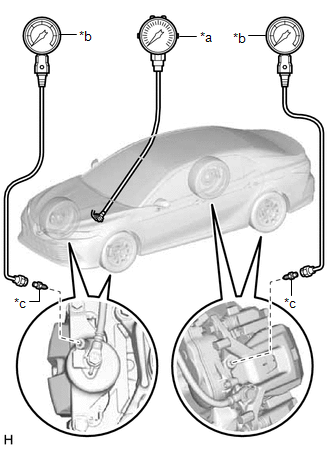

(b) Set a pedal effort gauge and SST, and connect the Techstream.

|

(1) Set a pedal effort gauge and SST. SST: 09709-29018 09709-00060 |

|

(2) Connect the Techstream to the DLC3 with the power switch off, the shift lever in P and the parking brake applied.

(3) Turn the power switch on (IG) and turn the Techstream on.

(4) Bleed air from SST (LSPV gauge).

(c) Inspect the reaction force pressure and servo pressure.

(1) Enter the following menus: Chassis / ABS/VSC/TRAC / Data List / Reaction Force Pressure and Servo Pressure.

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

|---|

|

Reaction Force Pressure |

|

Servo Pressure |

(2) Check the value output from "Reaction Force Pressure" and "Servo Pressure" by depressing the brake pedal.

Standard Result:

|

Pedal Effort |

Reaction Force Pressure (MPa) |

Servo Pressure (MPa) |

Front Right Wheel Hydraulic Pressure |

Rear Left Wheel Hydraulic Pressure |

|---|---|---|---|---|

|

50 N (5 kgf, 11.2 lbf) |

0 to 0.65 |

2.1 to 6.1 |

1.8 to 5.8 MPa (18.4 to 59.2 kgf/cm2, 261 to 841 psi) |

1.8 to 5.8 MPa (18.4 to 59.2 kgf/cm2, 261 to 841 psi) |

|

100 N (10 kgf, 22.5 lbf) |

0.53 to 1.33 |

4.5 to 8.5 |

4.2 to 8.2 MPa (42.9 to 83.7 kgf/cm2, 609 to 1189 psi) |

4.2 to 8.2 MPa (42.9 to 83.7 kgf/cm2, 609 to 1189 psi) |

|

150 N (15 kgf, 33.7 lbf) |

1.16 to 1.96 |

6.6 to 10.6 |

6.3 to 10.3 MPa (64.3 to 105.1 kgf/cm2, 914 to 1494 psi) |

6.3 to 10.3 MPa (64.3 to 105.1 kgf/cm2, 914 to 1494 psi) |

|

200 N (20 kgf, 45.0 lbf) |

1.83 to 2.63 |

7.1 to 11.1 |

6.8 to 10.8 MPa (69.4 to 110.2 kgf/cm2, 986 to 1566 psi) |

6.8 to 10.8 MPa (69.4 to 110.2 kgf/cm2, 986 to 1566 psi) |

Standard Result:

|

Pedal Effort |

Reaction Force Pressure (MPa) |

Servo Pressure (MPa) |

Front Left Wheel Hydraulic Pressure |

Rear Right Wheel Hydraulic Pressure |

|---|---|---|---|---|

|

50 N (5 kgf, 11.2 lbf) |

0 to 0.65 |

2.08 to 6.08 |

1.8 to 5.8 MPa (18.4 to 59.2 kgf/cm2, 261 to 841 psi) |

1.8 to 5.8 MPa (18.4 to 59.2 kgf/cm2, 261 to 841 psi) |

|

100 N (10 kgf, 22.5 lbf) |

0.53 to 1.33 |

4.48 to 8.48 |

4.2 to 8.2 MPa (42.9 to 83.7 kgf/cm2, 609 to 1189 psi) |

4.2 to 8.2 MPa (42.9 to 83.7 kgf/cm2, 609 to 1189 psi) |

|

150 N (15 kgf, 33.7 lbf) |

1.16 to 1.96 |

6.58 to 10.58 |

6.3 to 10.3 MPa (64.3 to 105.1 kgf/cm2, 914 to 1494 psi) |

6.3 to 10.3 MPa (64.3 to 105.1 kgf/cm2, 914 to 1494 psi) |

|

200 N (20 kgf, 45.0 lbf) |

1.83 to 2.63 |

7.1 to 11.1 |

6.8 to 10.8 MPa (69.4 to 110.2 kgf/cm2, 986 to 1566 psi) |

6.8 to 10.8 MPa (69.4 to 110.2 kgf/cm2, 986 to 1566 psi) |

(d) Remove the pedal effort gauge and SST.

(1) Remove the pedal effort gauge and SST, and bleed the brake line.

(e) Inspect the accumulator pressure.

(1) Enter the following menus: Chassis / ABS/VSC/TRAC / Data List / Accumulator Pressure and MT Voltage Value.

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

|---|

|

MT Voltage Value |

|

Accumulator Pressure |

(2) While fully depressing the brake pedal 4 or 5 times, check that the MT voltage value is 10 V or more once or more.

HINT:

Usually the MT voltage value is 0 V.

(3) After confirming that the booster pump motor stops, check the accumulator pressure.

Standard Result:

15 to 21 MPa

2. INSPECT BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY

(a) Check auxiliary battery voltage.

Standard Voltage:

11 to 14 V (while the power switch is off)

(b) Set a pedal effort gauge and SST, and connect the Techstream.

|

(1) Set a pedal effort gauge and SST. SST: 09709-29018 09709-00060 |

|

(2) Connect the Techstream to the DLC3 with the power switch off, the shift lever in P and the parking brake applied.

(3) Turn the power switch on (IG) and turn the Techstream on.

(4) Clear the DTCs.

(5) Bleed air from SST (LSPV gauge).

(c) Check operation without the brake booster.

(1) Inspect and adjust the brake pedal height.

|

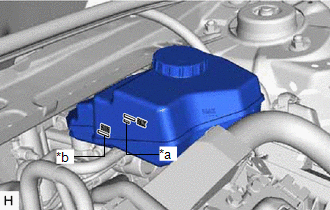

(2) Adjust the brake fluid level of the reservoir so that it is between the MIN line and fluid level support line. |

|

(3) Turn the Techstream on and enter the following menus: Chassis / ABS/VSC/TRAC / Utility / ECB (Electronically Controlled Brake system) Utility.

Chassis > ABS/VSC/TRAC > Utility

|

Tester Display |

|---|

|

ECB Utility |

(4) Select "Motor Invalid" on the "ECB (Electronically Controlled Brake system) Utility" screen.

(5) Perform "Motor Invalid" according to the display on the Techstream.

(6) Depress the brake pedal 40 times or more to return all the fluid in the accumulator back to the reservoir.

HINT:

A buzzer may sound due to low accumulator pressure. As this is not a malfunction, continue the procedure.

(7) Check that the brake pedal is firm.

(8) Enter the following menus: Chassis / ABS/VSC/TRAC / Data List / Stroke Sensor and Stroke Sensor 2.

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

|---|

|

Stroke Sensor |

|

Stroke Sensor2 |

(9) Check the values output from "Stroke Sensor" and "Stroke Sensor 2" by depressing the brake pedal.

Standard Result:

|

Pedal Effort |

Stroke Sensor (V) |

Stroke Sensor 2 (V) |

Front Right Wheel Hydraulic Pressure |

Rear Left Wheel Hydraulic Pressure |

|---|---|---|---|---|

|

200 N (20 kgf, 45.0 lbf) |

1.52 to 2.22 |

2.78 to 3.48 |

0.04 to 2.04 MPa (0.4 to 20.8 kgf/cm2, 6 to 296 psi) |

0.04 to 2.04 MPa (0.4 to 20.8 kgf/cm2, 6 to 296 psi) |

|

500 N (51 kgf, 112.4 lbf) |

1.81 to 2.51 |

2.49 to 3.19 |

2.06 to 4.06 MPa (21.0 to 41.4 kgf/cm2, 299 to 589 psi) |

2.06 to 4.06 MPa (21.0 to 41.4 kgf/cm2, 299 to 589 psi) |

Standard Result:

|

Pedal Effort |

Stroke Sensor (V) |

Stroke Sensor 2 (V) |

Front Left Wheel Hydraulic Pressure |

Rear Right Wheel Hydraulic Pressure |

|---|---|---|---|---|

|

200 N (20 kgf, 45.0 lbf) |

1.52 to 2.22 |

2.78 to 3.48 |

0.04 to 2.04 MPa (0.4 to 20.8 kgf/cm2, 6 to 296 psi) |

0.04 to 2.04 MPa (0.4 to 20.8 kgf/cm2, 6 to 296 psi) |

|

500 N (51 kgf, 112.4 lbf) |

1.81 to 2.51 |

2.49 to 3.19 |

2.06 to 4.06 MPa (21.0 to 41.4 kgf/cm2, 299 to 589 psi) |

2.06 to 4.06 MPa (21.0 to 41.4 kgf/cm2, 299 to 589 psi) |

(10) Remove the pedal effort gauge and SST, and bleed the brake system.

(11) Enter the following menus: Chassis / ABS/VSC/TRAC / Data List / Accumulator Pressure, and check the output pressure.

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

|---|

|

Accumulator Pressure |

Standard Result:

15 to 21 MPa

(12) Clear the DTCs.

3. INSPECT STROKE SIMULATOR

(a) Check auxiliary battery voltage.

Standard Voltage:

11 to 14 V (while the power switch is off)

(b) Connect the Techstream and set a pedal effort gauge.

(1) Set a pedal effort gauge.

(2) Connect the Techstream to the DLC3 with the power switch off, the shift lever in P and the parking brake applied.

(3) Turn the power switch on (IG) and turn the Techstream on.

(4) Clear the DTCs.

(c) Check operation with the brake booster.

(1) Turn the power switch on (IG).

(2) Enter the following menus: Chassis / ABS/VSC/TRAC / Data List / Stroke Sensor and Stroke Sensor 2.

Chassis > ABS/VSC/TRAC > Data List

|

Tester Display |

|---|

|

Stroke Sensor |

|

Stroke Sensor2 |

(3) Depress the brake pedal 4 or 5 times.

(4) Check the values output from "Stroke Sensor" and "Stroke Sensor 2" by depressing the brake pedal.

Standard Voltage:

|

Pedal Effort |

Stroke Sensor (V) |

Stroke Sensor 2 (V) |

|---|---|---|

|

50 N (5 kgf, 11.2 lbf) |

1.38 to 2.08 |

2.92 to 3.62 |

|

100 N (10 kgf, 22.5 lbf) |

1.58 to 2.28 |

2.72 to 3.42 |

|

150 N (15 kgf, 33.7 lbf) |

1.71 to 2.41 |

2.59 to 3.29 |

|

|

|

![2018 MY Camry HV [07/2017 - 09/2018]; BRAKE SYSTEM (OTHER): BRAKE FLUID: BLEEDING+](/t3Portal/stylegraphics/info.gif)