|

Last Modified: 02-14-2025 |

6.11:8.1.0 |

Doc ID: RM10000000157CF |

|

Model Year Start: 2018 |

Model: Camry HV |

Prod Date Range: [07/2017 - 08/2021] |

|

Title: THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function): Power Source Mode does not Change to ON (READY); 2018 - 2021 MY Camry HV [07/2017 - 08/2021] |

|

Power Source Mode does not Change to ON (READY)

|

DESCRIPTION

When the electrical key transmitter sub-assembly is in the cabin and the power switch is pressed, the certification ECU (smart key ECU assembly) receives a signal and changes the power source mode. Additionally, when the shift lever is in P and the brake pedal is depressed, the hybrid control system can be started by pressing the power switch. If the steering is unlocked, the hybrid control system can also be started by pressing the power switch with the shift lever in P and the brake pedal depressed.

Related Data List and Active Test Items

|

Problem Symptom

|

Data List and Active Test

|

|

Power source mode does not change to ON (READY)

|

Power Source Control

-

Stop Light Switch1

-

Steering Unlock Switch

-

Shift P Signal

-

IG Relay Monitor (Inside)

-

IG Relay Monitor (Outside)

-

Latch Circuit

-

Starter Request Signal

-

Power Supply Condition

Smart Key

-

Immobiliser

-

Engine Start Request

-

L Code Check

|

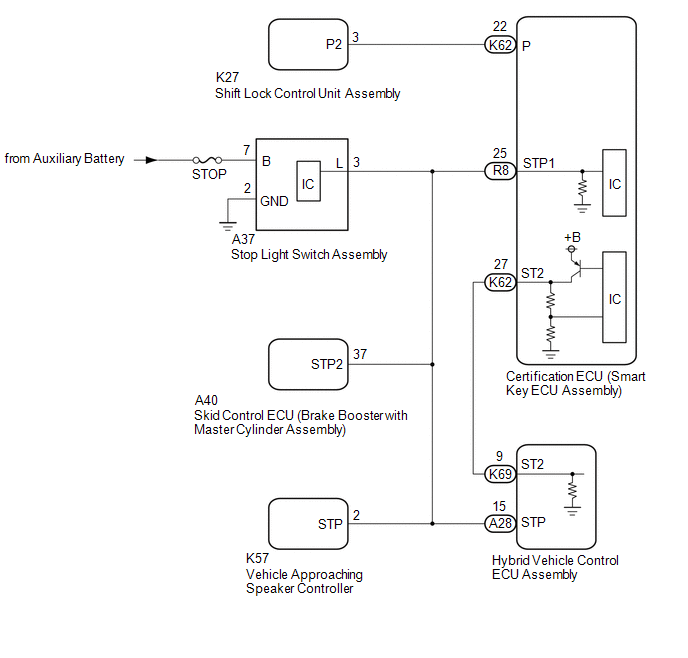

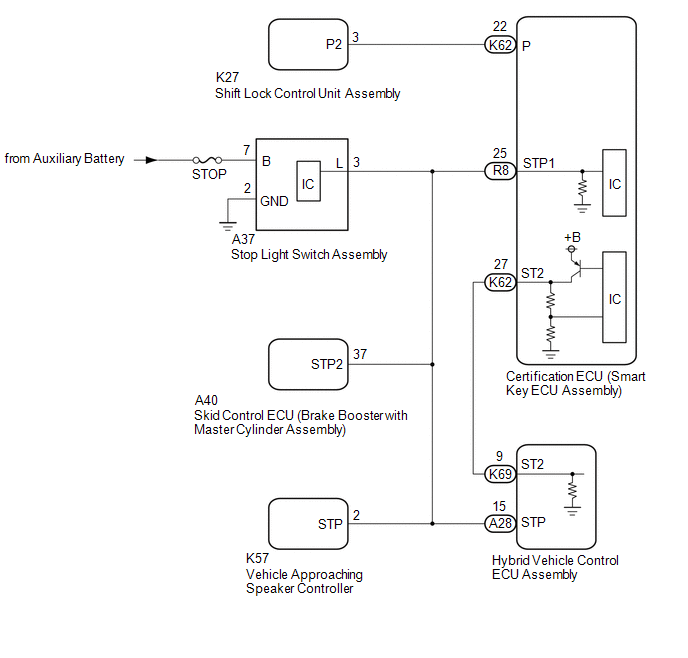

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

-

When using the Techstream with the power switch off, connect the Techstream to the DLC3 and turn a courtesy light switch on and off at intervals of 1.5 seconds or less until communication between the Techstream and the vehicle begins. Then select the vehicle type under manual mode and enter the following menus: Body Electrical / Smart Key. While using the Techstream, periodically turn a courtesy light switch on and off at intervals of 1.5 seconds or less to maintain communication between the Techstream and the vehicle.

-

The smart key system (for Start Function) uses the LIN communication system and CAN communication system. Inspect the communication function by following How to Proceed with Troubleshooting. Troubleshoot the smart key system (for Start Function) after confirming that the communication systems are functioning properly.

Click here

![2018 - 2022 MY Camry HV [07/2017 - 08/2022]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function): HOW TO PROCEED WITH TROUBLESHOOTING](/t3Portal/stylegraphics/info.gif)

-

If the smart key system (for Start Function) has been canceled, enable the system before performing troubleshooting.

Click here

![2018 - 2024 MY Camry HV [07/2017 - ]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function): CUSTOMIZE PARAMETERS](/t3Portal/stylegraphics/info.gif)

-

Inspect the fuses of circuits related to this system before performing the following procedure.

-

Before replacing the certification ECU (smart key ECU assembly) or electrical key transmitter sub-assembly, refer to Registration.

Click here

![2018 - 2019 MY Camry HV [07/2017 - 09/2019]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function): REGISTRATION](/t3Portal/stylegraphics/info.gif)

![2020 - 2022 MY Camry HV [09/2019 - 08/2022]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function): REGISTRATION](/t3Portal/stylegraphics/info.gif)

-

After completing repairs, confirm that the problem does not recur.

PROCEDURE

|

1.

|

CHECK POWER SWITCH CONDITION

|

(a) Get into the vehicle while carrying an electrical key transmitter sub-assembly.

(b) Move the shift lever to P.

(c) With the brake pedal released, check that pressing the power switch causes the power source mode to change.

|

Result

|

Proceed to

|

|

Power source mode changes : Off → on (ACC) → on (IG) → off

|

A

|

|

Power source mode does not change to on (ACC) or on (IG)

|

B

|

|

Power source mode changes to on (IG) but not to on (ACC)

|

C

|

|

Power source mode changes to on (ACC) but not to on (IG)

|

D

|

|

A

|

|

|

|

2.

|

READ VALUE USING TECHSTREAM (STOP LIGHT SWITCH1)

|

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Power Source Control / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Power Source Control > Data List

|

Tester Display

|

Measurement Item

|

Range

|

Normal Condition

|

Diagnostic Note

|

|

Stop Light Switch1

|

State of brake pedal

|

OFF or ON

|

OFF: Brake pedal released

ON: Brake pedal depressed

|

-

Use this item to determine if the stop light switch assembly is malfunctioning.

-

The hybrid control system cannot be started when this item is OFF.

-

If the stop light switch assembly is malfunctioning, the hybrid control system can be started by pressing and holding the power switch for a certain period of time.

|

Body Electrical > Power Source Control > Data List

|

Tester Display

|

|

Stop Light Switch1

|

OK:

The Techstream display changes correctly in response to the brake pedal operation.

|

OK

|

|

|

|

3.

|

READ VALUE USING TECHSTREAM (SHIFT P SIGNAL)

|

(a) Enter the following menus: Body Electrical / Power Source Control / Data List.

(b) Read the Data List according to the display on the Techstream.

Body Electrical > Power Source Control > Data List

|

Tester Display

|

Measurement Item

|

Range

|

Normal Condition

|

Diagnostic Note

|

|

Shift P Signal

|

Shift position P

|

OFF or ON

|

OFF: Shift lever not in P

ON: Shift lever in P

|

Use this item to determine whether the shift lever position switch (P) is malfunctioning.

|

Body Electrical > Power Source Control > Data List

|

Tester Display

|

|

Shift P Signal

|

OK:

The Techstream display changes correctly in response to the shift lever operation.

|

OK

|

|

|

|

4.

|

READ VALUE USING TECHSTREAM (STARTER REQUEST SIGNAL)

|

(a) Enter the following menus: Body Electrical / Power Source Control / Data List.

(b) Read the Data List according to the display on the Techstream.

Body Electrical > Power Source Control > Data List

|

Tester Display

|

Measurement Item

|

Range

|

Normal Condition

|

Diagnostic Note

|

|

Starter Request Signal

|

Hybrid control system start request signal status

|

OFF or ON

|

OFF: The power switch is not pressed

ON: With the shift lever in P and the brake pedal depressed, the power switch is pressed and held

|

-

When the hybrid control system cannot be started due to a start request signal malfunction, OFF is displayed.

-

When the power switch is pressed, the duration of time that ON is displayed will be extremely short. As such, the power switch needs to be pressed and held for a certain period of time.

|

Body Electrical > Power Source Control > Data List

|

Tester Display

|

|

Starter Request Signal

|

NOTICE:

Check that the key indicator display is displayed on the multi-information display in the combination meter assembly, and then press the power switch.

OK:

The Techstream display changes correctly in response to the power switch operation.

|

OK

|

|

|

|

5.

|

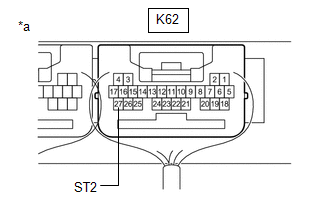

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - HYBRID VEHICLE CONTROL ECU ASSEMBLY)

|

(a) Disconnect the K62 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the K69 hybrid vehicle control ECU assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

K62-27 (ST2) - K69-9 (ST2)

|

Always

|

Below 1 Ω

|

|

K62-27 (ST2) or K69-9 (ST2) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

OK

|

|

|

|

6.

|

CHECK CERTIFICATION ECU (SMART KEY ECU ASSEMBLY)

|

(a) Connect the K62 certification ECU (smart key ECU assembly) connector.

(b) Connect the K69 hybrid vehicle control ECU assembly connector.

|

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

K62-27 (ST2) - Body ground

|

With the brake pedal depressed, the power switch is pressed and held → After approx. 3 sec. has elapsed, the power switch is released

|

8.5 V or higher → 1.0 V or less

|

|

|

|

*a

|

Component with harness connected

(Certification ECU (Smart Key ECU Assembly))

|

|

|

| OK |

|

GO TO HYBRID CONTROL SYSTEM

for Nickel Metal Hybrid Battery: Click here

![2018 - 2024 MY Camry HV [07/2017 - ]; HYBRID / BATTERY CONTROL: HYBRID CONTROL SYSTEM (for NICKEL METAL HYDRIDE BATTERY): HOW TO PROCEED WITH TROUBLESHOOTING](/t3Portal/stylegraphics/info.gif)

for Lithium-ion Battery: Click here

![2018 - 2024 MY Camry HV [07/2017 - ]; HYBRID / BATTERY CONTROL: HYBRID CONTROL SYSTEM (for LITHIUM-ION BATTERY): HOW TO PROCEED WITH TROUBLESHOOTING](/t3Portal/stylegraphics/info.gif)

|

|

7.

|

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH ASSEMBLY - POWER SOURCE AND BODY GROUND)

|

(a) Measure the voltage and resistance according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

A37-7 (B) - Body ground

|

Power switch off

|

11 to 14 V

|

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

A37-2 (GND) - Body ground

|

Always

|

Below 1 Ω

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

OK

|

|

|

|

8.

|

CHECK STOP LIGHT SWITCH ASSEMBLY

|

(a) Check the stop light switch assembly.

Click here

![2018 - 2020 MY Camry HV [07/2017 - 10/2020]; LIGHTING (EXT): STOP LIGHT SWITCH: ON-VEHICLE INSPECTION](/t3Portal/stylegraphics/info.gif)

![2021 - 2024 MY Camry HV [10/2020 - ]; LIGHTING (EXT): STOP LIGHT SWITCH: ON-VEHICLE INSPECTION](/t3Portal/stylegraphics/info.gif)

|

OK

|

|

|

|

9.

|

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - STOP LIGHT SWITCH ASSEMBLY)

|

(a) Disconnect the A37 stop light switch assembly connector.

(b) Disconnect the R8 certification ECU (smart key ECU assembly) connector.

(c) Disconnect the A28 hybrid vehicle control ECU assembly connector.

(d) Disconnect the K27 shift lock control unit assembly connector.

(e) Disconnect the A40 skid control ECU (brake booster with master cylinder assembly) connector.

(f) Disconnect the K57 vehicle approaching speaker controller connector.

(g) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

R8-25 (STP1) - A37-3 (L)

|

Always

|

Below 1 Ω

|

|

R8-25 (STP1) or A37-3 (L) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|

10.

|

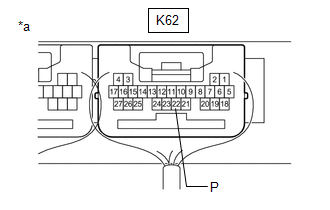

CHECK SHIFT LOCK CONTROL UNIT ASSEMBLY

|

|

(a) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

K62-22 (P) - Body ground

|

Shift lever in P → Shift lever not in P

|

9 V or higher → 2.76 V or less

|

|

|

|

*a

|

Component with harness connected

(Certification ECU (Smart Key ECU Assembly))

|

|

|

|

11.

|

CHECK STEERING LOCK FUNCTION

|

(a) Check that the steering unlocks when the power switch is turned on (ACC).

OK:

The steering unlocks.

|

OK

|

|

|

|

12.

|

CHECK SECURITY INDICATOR LIGHT (IMMOBILISER FUNCTION UNSET)

|

(a) Get into the vehicle while carrying an electrical key transmitter sub-assembly.

(b) Move the shift lever to P.

(c) Press the power switch with the brake pedal released and check that the security indicator light changes from blinking to off at the same time that the power source mode changes to on (ACC).

OK:

The security indicator light changes from blinking to off at the same time that the power source mode changes to on (ACC).

HINT:

The immobiliser function can be determined to be operating correctly if the security indicator light changes from blinking to off at the same time that the power source mode changes to on (ACC).

|

13.

|

CHECK HARNESS AND CONNECTOR (CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) - SHIFT LOCK CONTROL UNIT ASSEMBLY)

|

(a) Disconnect the K62 certification ECU (smart key ECU assembly) connector.

(b) Disconnect the K27 shift lock control unit assembly connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

K62-22 (P) - K27-3 (P2)

|

Always

|

Below 1 Ω

|

|

K62-22 (P) or K27-3 (P2) - Other terminals and body ground

|

Always

|

10 kΩ or higher

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR

|

|