| Last Modified: 02-14-2025 | 6.11:8.1.0 | Doc ID: RM10000000154Z6 |

| Model Year Start: 2018 | Model: Camry HV | Prod Date Range: [07/2017 - ] |

| Title: LIGHTING (INT): LIGHTING SYSTEM: Ambient Illumination Light Circuit; 2018 - 2024 MY Camry HV [07/2017 - ] | ||

|

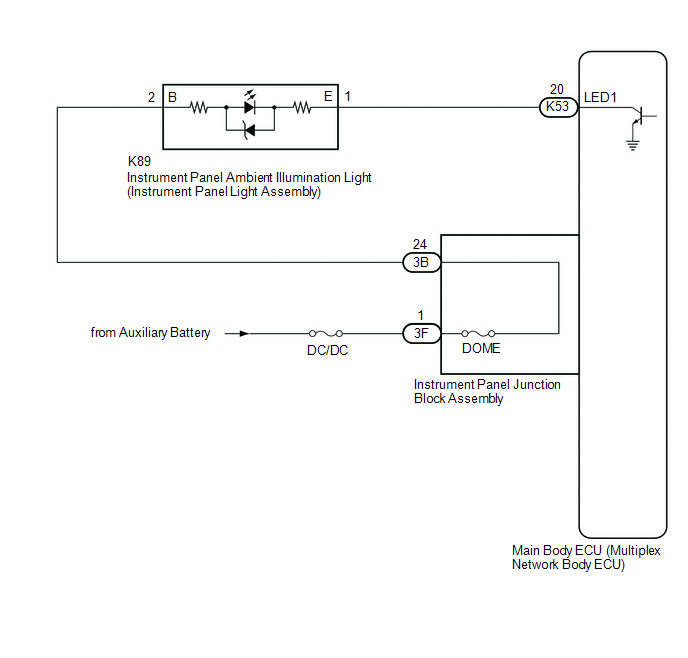

Ambient Illumination Light Circuit |

DESCRIPTION

The main body ECU (multiplex network body ECU) controls the instrument panel ambient illumination light (instrument panel light assembly).

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

PROCEDURE

|

1. |

PERFORM ACTIVE TEST USING TECHSTREAM |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Main Body / Active Test.

(e) Perform the Active Test according to the display on the Techstream.

Body Electrical > Main Body > Active Test

|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Interior Illumination Light1 |

Instrument panel ambient illumination light (Instrument panel light assembly) |

OFF or ON |

Preconditions for using the Active Test to check dimmer controlled illumination:

|

Body Electrical > Main Body > Active Test

|

Tester Display |

|---|

|

Interior Illumination Light1 |

OK:

Instrument panel ambient illumination light comes on.

| OK |

|

|

|

2. |

INSPECT INSTRUMENT PANEL LIGHT ASSEMBLY |

(a) Remove the instrument panel ambient illumination light (instrument panel light assembly).

(b) Inspect the instrument panel ambient illumination light (instrument panel light assembly).

| NG |

|

REPLACE INSTRUMENT PANEL AMBIENT ILLUMINATION LIGHT (INSTRUMENT PANEL LIGHT ASSEMBLY) |

|

|

3. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

(a) Disconnect the 3F instrument panel junction block assembly connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3F-1 - Body ground |

Power switch off |

11 to 14 V |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

4. |

CHECK INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

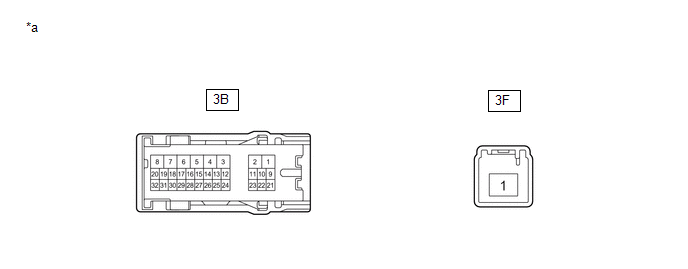

*a |

Component without harness connected (Instrument Panel Junction Block Assembly) |

- |

- |

(a) Disconnect the 3B instrument panel junction block assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3B-24 - 3F-1 |

Always |

Below 1 Ω |

| NG |

|

|

|

5. |

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY - INSTRUMENT PANEL LIGHT ASSEMBLY) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

3B-24 - K89-2 (B) |

Always |

Below 1 Ω |

|

3B-24 or K89-2 (B) - Body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

6. |

CHECK HARNESS AND CONNECTOR (INSTRUMENT PANEL LIGHT ASSEMBLY - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

(a) Disconnect the K53 main body ECU (multiplex network body ECU) connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

K89-1 (E) - K53-20 (LED1) |

Always |

Below 1 Ω |

|

K89-1 (E) or K53-20 (LED1) - Body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

|

![2018 - 2019 MY Camry HV [07/2017 - 09/2019]; THEFT DETERRENT / KEYLESS ENTRY: SMART KEY SYSTEM (for Start Function): REGISTRATION](/t3Portal/stylegraphics/info.gif)