| Last Modified: 02-14-2025 | 6.11:8.1.0 | Doc ID: RM1000000014V34 |

| Model Year Start: 2018 | Model: Camry HV | Prod Date Range: [07/2017 - 09/2018] |

| Title: HEATING / AIR CONDITIONING: COMPRESSOR: INSTALLATION; 2018 MY Camry HV [07/2017 - 09/2018] | ||

INSTALLATION

PROCEDURE

1. ADJUST COMPRESSOR OIL

|

(a) When replacing the compressor with motor assembly with a new one, gradually discharge the inert gas from the service valve, and drain the following amount of oil from the new compressor with motor assembly before installation. Standard: (Oil capacity inside the new compressor with motor assembly: 120 to 135 cc (4.06 to 4.56 fl. oz)) - (Remaining oil amount in the removed compressor with motor assembly) = (Oil amount to be removed from the new compressor) NOTICE:

|

|

2. INSTALL COMPRESSOR WITH MOTOR ASSEMBLY

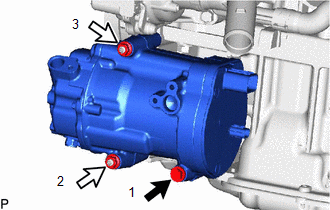

(a) Using an E8 "TORX" socket wrench, temporarily install the compressor with motor assembly with the 2 stud bolts.

Torque:

5.0 N·m {51 kgf·cm, 44 in·lbf}

(b) Install the compressor with motor assembly with the bolt and 2 nuts.

|

Bolt |

|

Nut |

Torque:

24.5 N·m {250 kgf·cm, 18 ft·lbf}

HINT:

Tighten the bolt and nuts in the order shown in the illustration.

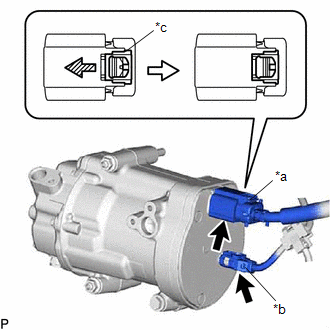

(c) Connect the connector (B).

|

*a |

Connector (A) |

|

*b |

Connector (B) |

|

*c |

Green-colored Lock |

|

Slide |

(d) Remove the insulating tape from the connector (A).

(e) Connect the connector (A) and slide the green-colored lock as shown in the illustration to securely lock it.

CAUTION:

Make sure to wear insulated gloves.

NOTICE:

Make sure that the connector is connected securely.

(f) Connect the 2 connectors.

3. CONNECT NO. 1 COOLER REFRIGERANT DISCHARGE HOSE SUB-ASSEMBLY

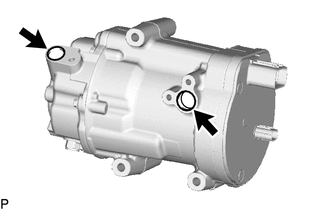

(a) Remove the vinyl tape from the No. 1 cooler refrigerant discharge hose sub-assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the compressor with motor assembly.

Compressor Oil:

ND-OIL 11 or equivalent

(c) Install the O-ring to the No. 1 cooler refrigerant discharge hose sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(d) Connect the No. 1 cooler refrigerant discharge hose sub-assembly to the compressor with motor assembly with the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

4. CONNECT SUCTION HOSE SUB-ASSEMBLY

(a) Remove the vinyl tape from the suction hose sub-assembly.

(b) Sufficiently apply compressor oil to a new O-ring and the fitting surface of the compressor with motor assembly.

Compressor Oil:

ND-OIL 11 or equivalent

(c) Install the O-ring to the suction hose sub-assembly.

NOTICE:

Keep the O-ring and O-ring fitting surface free of foreign matter.

(d) Connect the suction hose sub-assembly to the compressor with motor assembly with the bolt.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

5. INSTALL INLET AIR CLEANER ASSEMBLY

6. INSTALL COOL AIR INTAKE DUCT SEAL

7. INSTALL SERVICE PLUG GRIP

8. CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT

9. WARM UP COMPRESSOR

10. INSPECT FOR REFRIGERANT LEAK

|

|

|

![2018 - 2024 MY Camry HV [07/2017 - ]; HYBRID / BATTERY CONTROL: INVERTER WITH CONVERTER: INSTALLATION+](/t3Portal/stylegraphics/info.gif)