| Last Modified: 02-14-2025 | 6.11:8.1.0 | Doc ID: RM1000000014V1C |

| Model Year Start: 2018 | Model: Camry HV | Prod Date Range: [07/2017 - 09/2018] |

| Title: HEATING / AIR CONDITIONING: AIR CONDITIONING SYSTEM: B1423; Open in Pressure Sensor Circuit / Abnormal Refrigerant Pressure; 2018 MY Camry HV [07/2017 - 09/2018] | ||

|

DTC |

B1423 |

Open in Pressure Sensor Circuit / Abnormal Refrigerant Pressure |

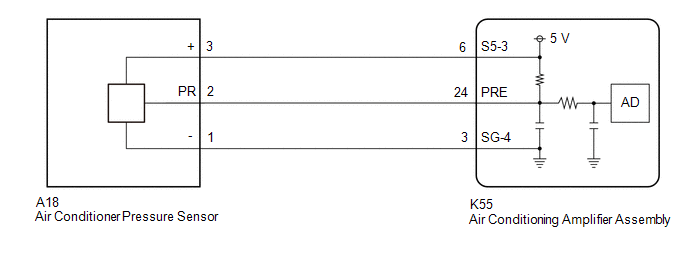

DESCRIPTION

This DTC is stored if refrigerant pressure on the high pressure side is extremely low (196 kPaG (2.0 kgf/cm2, 28 psi) or less) or extremely high (2812 kPaG (28.7 kgf/cm2, 408 psi) or more). The air conditioner pressure sensor, which is installed to the high pressure side pipe to detect refrigerant pressure, sends a refrigerant pressure signal to the air conditioning amplifier assembly. The air conditioning amplifier assembly converts this signal to a pressure value according to the sensor characteristics and uses it to control the compressor.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

Memory |

|---|---|---|---|---|

|

B1423 |

Open in Pressure Sensor Circuit / Abnormal Refrigerant Pressure |

|

|

- |

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

If DTC B1423 and B14B8 are output at the same time, troubleshoot for DTC B14B8 first.

PROCEDURE

|

1. |

PERFORM REFRIGERANT SHORTAGE CHECK |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Utility / Refrigerant Gas Volume Check.

Body Electrical > Air Conditioner > Utility

|

Tester Display |

|---|

|

Refrigerant Gas Volume Check |

(e) Check that the following conditions are met and perform the refrigerant shortage check according to the display on the Techstream.

Measurement Condition:

|

Item |

Condition |

|---|---|

|

A/C switch |

On |

|

Ambient temperature* |

0 to 49°C (32 to 120°F) |

|

Blower speed |

HI |

*: If the ambient temperature is not within the range shown, do not perform this check.

|

Result |

Amount of Refrigerant |

|---|---|

|

Refrigerant correct |

Correct |

|

Refrigerant shortage |

Insufficient |

OK:

"Refrigerant correct" is displayed on the Techstream.

| NG |

|

|

|

2. |

CHECK REFRIGERANT PRESSURE |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Turn the Techstream on.

(d) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(e) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Regulator Pressure Sensor |

Air conditioner pressure sensor |

Min.: -66.2 psi (gauge) Max.: 478.0 psi (gauge) |

Actual refrigerant pressure displayed |

|

Body Electrical > Air Conditioner > Data List

|

Tester Display |

|---|

|

Regulator Pressure Sensor |

(f) Install a manifold gauge set.

(g) Read the manifold gauge set with the following conditions met.

Measurement Condition:

|

Item |

Condition |

|---|---|

|

Vehicle doors |

Fully open |

|

Temperature setting |

MAX COLD |

|

Blower speed |

HI |

|

A/C switch |

On |

|

Recirculation/fresh switch |

RECIRCULATION |

|

Interior temperature |

25 to 35°C (77 to 95°F) |

Standard Pressure:

Low pressure side

150 to 250 kPa (1.5 to 2.5 kgf/cm2, 22 to 36 psi)

High pressure side

1370 to 1570 kPa (14 to 16 kgf/cm2, 199 to 228 psi)

(h) Compare the values displayed in the Data List and on the manifold gauge set.

OK:

The values displayed in the Data List and on the manifold gauge set match.

| NG |

|

|

|

3. |

CHECK REFRIGERANT HIGH PRESSURE HISTORY |

(a) Connect the Techstream to the DLC3.

(b) Turn the power switch on (IG).

(c) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(d) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Refrigerant High Pressure History |

Refrigerant high pressure history |

Min.: 0 Max.: 255 |

Number of times refrigerant high pressure history stored displayed |

- |

Body Electrical > Air Conditioner > Data List

|

Tester Display |

|---|

|

Refrigerant High Pressure History |

|

Result |

Proceed to |

|---|---|

|

The value is 0 |

A |

|

The value is not 0 |

B |

| A |

|

|

|

4. |

INSPECT COOLING FAN SYSTEM |

(a) Check if the cooling fan operates normally.

| NG |

|

|

|

5. |

RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM |

(a) Recover the refrigerant from the air conditioning system using a refrigerant recovery unit.

|

|

6. |

CHARGE AIR CONDITIONING SYSTEM WITH REFRIGERANT |

|

|

7. |

PERFORM REFRIGERANT HIGH PRESSURE HISTORY CLEAR |

(a) Clear the refrigerant high pressure history stored in the air conditioning amplifier assembly.

| NEXT |

|

END |

|

8. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE CIRCUIT) |

|

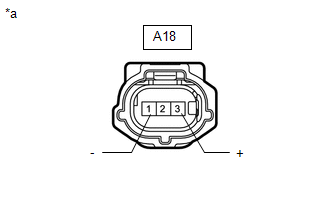

*a |

Front view of wire harness connector (to Air Conditioner Pressure Sensor) |

(a) Disconnect the A18 air conditioner pressure sensor connector.

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A18-3 (+) - A18-1 (-) |

Power switch on (IG) |

4.75 to 5.25 V |

| NG |

|

|

|

9. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - BODY GROUND) |

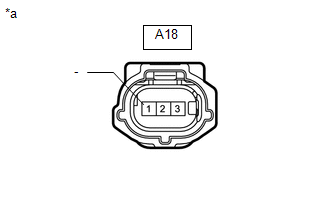

|

*a |

Front view of wire harness connector (to Air Conditioner Pressure Sensor) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A18-1 (-) - Body ground |

Always |

Below 1 Ω |

| NG |

|

|

|

10. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the K55 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A18-2 (PR) - K55-24 (PRE) |

Always |

Below 1 Ω |

|

A18-2 (PR) or K55-24 (PRE) - Other terminals and body ground |

Always |

10 kΩ or higher |

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

11. |

INSPECT AIR CONDITIONER PRESSURE SENSOR (SENSOR SIGNAL CIRCUIT) |

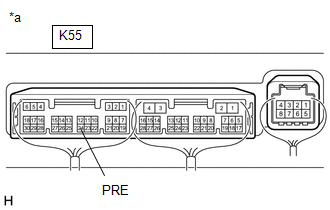

|

*a |

Component with harness connected (Air Conditioning Amplifier Assembly) |

(a) Measure the voltage with the following conditions met.

Measurement Condition:

|

Item |

Condition |

|---|---|

|

Vehicle doors |

Fully open |

|

Temperature setting |

MAX COLD |

|

Blower speed |

HI |

|

A/C switch |

On |

|

Recirculation/fresh switch |

RECIRCULATION |

|

Interior temperature |

25 to 35°C (77 to 95°F) |

NOTICE:

- If refrigerant pressure on the high pressure side becomes extremely high during the inspection (if the voltage exceeds 4.61 V), a fail-safe function will stop compressor operation. In this case, make sure to measure the voltage before the fail-safe function operates.

- It is necessary to measure the voltage for a certain amount of time (approximately 10 minutes) because the malfunction may recur after a while.

HINT:

When the ambient air temperature is low(below -1.5°C (29.3°F)), the compressor with pulley will be stopped, due to inputs of the thermistor assembly and No. 1 cooler thermistor, to prevent the evaporator from freezing. In this case, perform the inspection in a warm indoor environment.

(1) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

K55-24 (PRE) - Body ground |

Power switch on (IG) (A/C switch: On) |

0.74 to 4.61 V* |

*: While sensor voltage is 5 V.

(b) Connect the Techstream to the DLC3.

(c) Turn the power switch on (IG).

(d) Turn the Techstream on.

(e) Enter the following menus: Body Electrical / Air Conditioner / Data List.

(f) Read the Data List according to the display on the Techstream.

Body Electrical > Air Conditioner > Data List

|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Regulator Pressure Sensor |

Air conditioner pressure sensor |

Min.: -66.2 psi (gauge) Max.: 478.0 psi (gauge) |

Actual refrigerant pressure displayed |

|

Body Electrical > Air Conditioner > Data List

|

Tester Display |

|---|

|

Regulator Pressure Sensor |

OK:

The voltage and value displayed in the Data List change.

|

Result |

Proceed to |

|---|---|

|

OK |

A |

|

NG (The voltage changes but the value displayed in the Data List does not change.) |

|

|

NG (The voltage does not change.) |

B |

| A |

|

| B |

|

|

12. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the K55 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A18-1 (-) - K55-3 (SG-4) |

Always |

Below 1 Ω |

|

A18-1 (-) or K55-3 (SG-4) - Other terminals and body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

13. |

CHECK HARNESS AND CONNECTOR (AIR CONDITIONER PRESSURE SENSOR - AIR CONDITIONING AMPLIFIER ASSEMBLY) |

(a) Disconnect the K55 air conditioning amplifier assembly connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

A18-3 (+) - K55-6 (S5-3) |

Always |

Below 1 Ω |

|

A18-3 (+) or K55-6 (S5-3) - Other terminals and body ground |

Always |

10 kΩ or higher |

| OK |

|

| NG |

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

14. |

REPAIR AIR CONDITIONING SYSTEM LEAK |

(a) Identify the area where refrigerant is leaking from.

(b) Repair the identified area of the air conditioning system.

(c) Evacuate the air conditioning system.

| NEXT |

|

|

|

|

![2018 MY Camry HV [07/2017 - 09/2018]; HEATING / AIR CONDITIONING: AIR CONDITIONING SYSTEM: B14B8; Refrigerant Shortage](/t3Portal/stylegraphics/info.gif)