- Replacement of throttle body with motor assembly

- Cleaning the deposits from the throttle body with motor assembly

- Replacement of engine assembly

- Replacement of cylinder head sub-assembly

- Replacement of camshaft (for intake or exhaust camshaft)

- Replacement of camshaft timing gear assembly

- Replacement of camshaft timing exhaust gear assembly

- Replacement of fuel injector assembly (for port injection)

- Replacement of fuel injector assembly (for direct injection)

- Replacement of fuel pump assembly (for high pressure side)

- Replacement of engine coolant temperature sensor

- Replacement of spark plug

- Replacement of ignition coil assembly

- Air leaks from intake system

- Gas leak from exhaust system is repaired

- Replacement of knock control sensor

| Last Modified: 11-20-2023 | 6.11:8.1.0 | Doc ID: RM100000001T5F1 |

| Model Year Start: 2021 | Model: Camry | Prod Date Range: [10/2020 - 08/2022] |

| Title: 2GR-FKS (ENGINE MECHANICAL): ENGINE UNIT: REMOVAL; 2021 - 2022 MY Camry [10/2020 - 08/2022] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during engine unit removal/installation are shown below.

Necessary Procedure After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

| *1: When the ECM is replaced with a new one, reset memory is unnecessary. | |||

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane Tracing Assist System |

|

|

Pre-collision System |

|||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

||

|

Panoramic view monitor system |

|||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

|

Inspection After Repair |

|

|

|

Replacement of automatic transaxle assembly |

|

|

|

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

|

||

|

Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

|

||

|

Replacement of ECM |

Code registration |

|

|

|

Replacement of automatic transaxle fluid |

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

Replacement of front bumper assembly |

Front television camera view adjustment |

Panoramic view monitor system |

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

|

||

|

Front wheel alignment adjustment |

|

|

|

PROCEDURE

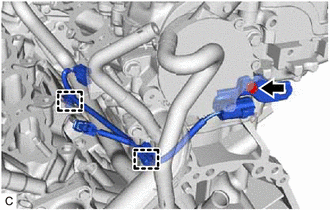

1. REMOVE KNOCK CONTROL SENSOR

2. REMOVE SENSOR WIRE

|

(a) Disengage the 2 clamps and remove the bolt and sensor wire. |

|

3. REMOVE IGNITION COIL ASSEMBLY

4. REMOVE VACUUM PUMP ASSEMBLY

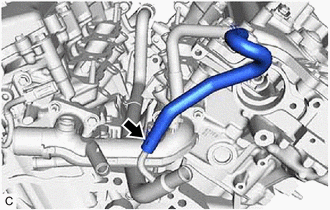

5. REMOVE NO. 3 WATER BY-PASS HOSE

|

(a) Slide the clip and remove the No. 3 water by-pass hose from the water inlet pipe. |

|

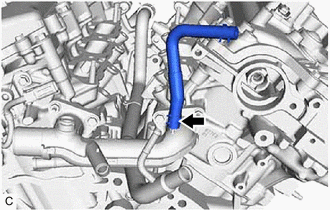

6. REMOVE NO. 2 WATER BY-PASS HOSE

|

(a) Slide the clip and remove the No. 2 water by-pass hose from the water outlet. |

|

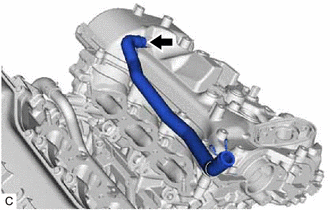

7. REMOVE VENTILATION HOSE

|

(a) Slide the clip and remove the ventilation hose from the PCV valve (ventilation valve sub-assembly). |

|

8. REMOVE NO. 2 VENTILATION HOSE

|

(a) Slide the clip and remove the No. 2 ventilation hose from the cylinder head cover sub-assembly. |

|

9. REMOVE V-RIBBED BELT

10. REMOVE GENERATOR ASSEMBLY

11. REMOVE COMPRESSOR ASSEMBLY WITH MAGNETIC CLUTCH

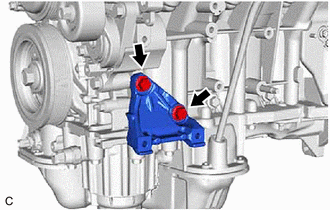

12. REMOVE NO. 1 COMPRESSOR MOUNTING BRACKET

|

(a) Remove the 2 bolts and No. 1 compressor mounting bracket from the cylinder block sub-assembly. |

|

13. REMOVE NO. 2 IDLER PULLEY SUB-ASSEMBLY

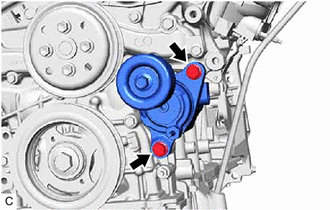

14. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

|

(a) Remove the 2 bolts and V-ribbed belt tensioner assembly. |

|

15. REMOVE WATER PUMP PULLEY

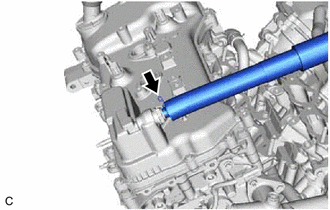

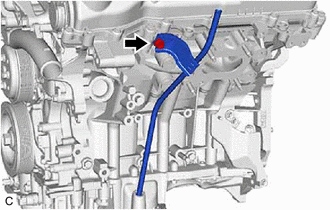

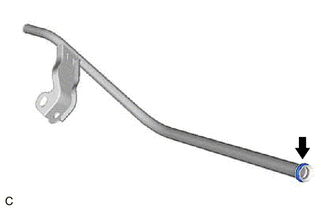

16. REMOVE ENGINE OIL LEVEL DIPSTICK GUIDE

(a) Remove the engine oil level dipstick from the engine oil level dipstick guide.

|

(b) Remove the bolt and engine oil level dipstick guide from the camshaft housing sub-assembly LH and oil pan sub-assembly. |

|

|

(c) Remove the engine oil level dipstick guide O-ring from the engine oil level dipstick guide. |

|

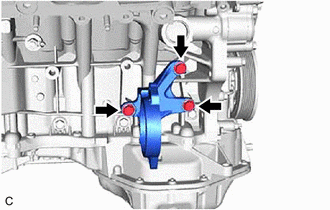

17. REMOVE DRIVE SHAFT BEARING BRACKET

|

(a) Remove the 3 bolts and drive shaft bearing bracket from the cylinder block sub-assembly. |

|

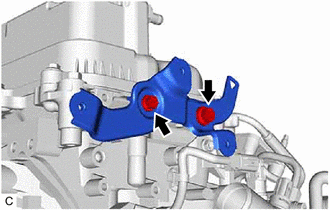

18. REMOVE WIRE HARNESS CLAMP BRACKET

|

(a) Remove the bolt and wire harness clamp bracket from the camshaft housing sub-assembly LH. |

|

|

(b) Remove the bolt and wire harness clamp bracket from the camshaft housing sub-assembly. |

|

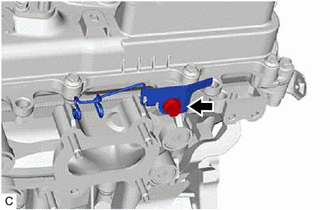

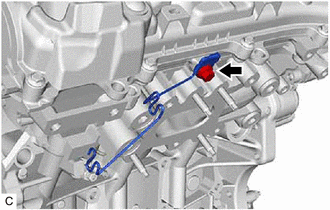

19. REMOVE WATER FILLER BRACKET

|

(a) Remove the 2 bolts and water filler bracket from the camshaft housing sub-assembly LH. |

|

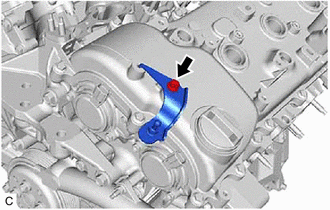

20. REMOVE ENGINE COVER BRACKET

|

(a) Remove the bolt and engine cover bracket from the cylinder head cover sub-assembly LH. |

|

|

|

|

![2021 - 2024 MY Camry [10/2020 - ]; PRE-COLLISION: PRE-COLLISION SYSTEM: INITIALIZATION](/t3Portal/stylegraphics/info.gif)