| Last Modified: 11-20-2023 | 6.11:8.1.0 | Doc ID: RM100000001T3GY |

| Model Year Start: 2021 | Model: Camry | Prod Date Range: [10/2020 - ] |

| Title: UB80F (AUTOMATIC TRANSMISSION / TRANSAXLE): AUTOMATIC TRANSAXLE SYSTEM: PRECAUTION; 2021 - 2024 MY Camry [10/2020 - ] | ||

PRECAUTION

IGNITION SWITCH EXPRESSION

HINT:

The type of ignition switch used on this model differs depending on the specifications of the vehicle. The expressions listed in the table below are used in this section.

|

Expression |

Ignition Switch (Position) |

Engine Switch (Condition) |

|---|---|---|

|

Ignition Switch off |

LOCK |

Off (Lock) |

|

Ignition Switch ACC |

ACC |

On (ACC) |

|

Ignition Switch ON |

ON |

On (IG) |

|

Engine Start |

START |

On (Start) |

PRECAUTION FOR DISCONNECTING CABLE FROM NEGATIVE BATTERY TERMINAL

NOTICE:

When disconnecting the cable from the negative (-) battery terminal, initialize the following system(s) after the cable is reconnected:

|

System |

See Procedure |

|---|---|

|

Lane Tracing Assist System |

|

|

Pre-collision System |

|

|

Parking Assist Monitor System |

|

|

Panoramic View Monitor System |

PROCEDURES NECESSARY WHEN ECU OR OTHER PARTS ARE REPLACED

NOTICE:

-

If automatic transaxle parts are replaced, perform the following as necessary referring to the table below:

Parts Replacement Compensation Table

*1: When replacing with a new ECM *2: When replacing with an ECM which was installed to another vehicle

Replaced Part

Transaxle Compensation Code

Reset Memory (Learned Values)

Road Test

Automatic transaxle assembly

Input

Reset

Necessary

Transmission valve body assembly

Initialize

Reset

Necessary

Solenoid (SL1, SL2, SL3, SL4, SL5 and/or SL6) valve

Initialize

Reset

Necessary

ECM

(If possible, read the transaxle compensation code from the previous ECM)

Possible to read transaxle compensation code

Input (Into the new ECM)

-*1

Reset*2

Necessary

Impossible to read transaxle compensation code

Initialize

-*1

Reset*2

Necessary

- Perform Registration (VIN registration) when replacing the ECM.

- Before replacing the ECM or certification ECU (smart key ECU assembly), refer to Registration.

-

If either of the following conditions is met, perform ATF Thermal Degradation Estimate Reset.

-

The ATF has been replaced.

HINT:

If 50000 or more is displayed for the Data List item "ATF Thermal Degradation Estimate", thermal degradation of the ATF is suspected. Perform ATF Thermal Degradation Estimate Reset after replacing the ATF.

- Approximately 50% or more of the ATF has been replaced during a repair of the transaxle or a similar operation.

-

The ATF has been replaced.

HANDLING PRECAUTIONS

CAUTION:

-

Do not perform a stall test if there are any people or objects near the vehicle.

- The vehicle could begin moving suddenly, resulting in a serious accident.

-

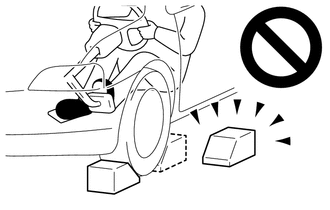

Do not perform a stall test if any wheel chocks are out of position.

- The vehicle could begin moving suddenly, resulting in a serious accident.

-

Do not perform the stall test on a slippery or low-friction surface that could allow the tires to spin.

- The vehicle could begin moving suddenly, resulting in a serious accident.

-

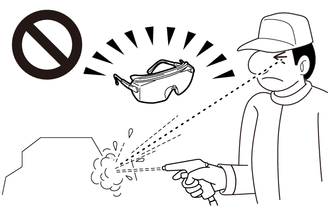

Do not blow compressed air without wearing safety glasses.

- Automatic Transaxle Fluid (ATF) could enter your eyes, possibly resulting in blindness.

NOTICE:

- The automatic transaxle assembly is composed of precision-made parts. Careful inspection before reassembly is necessary because even a small nick could cause fluid leakage or affect performance.

- The procedures are organized so that you work on only one component group at a time. This will help avoid confusion with similar-looking parts of different sub-assemblies being on your workbench at the same time.

- The component groups are inspected and repaired from the converter housing side.

- Whenever possible, complete the inspection, repair and reassembly before proceeding to the next component group. If a defect is found in a certain component group during reassembly, inspect and repair this group immediately. If a component group cannot be assembled because parts are being ordered, be sure to keep all parts of the group in a separate container while proceeding with disassembly, inspection, repair and reassembly of other component groups.

- Use of Toyota Genuine ATF WS is recommended.

- All disassembled parts should be cleaned, and compressed air should be blown through any fluid passages and holes.

- Dry all parts with compressed air. Never use a piece of cloth.

- The recommended ATF or kerosene should be used for cleaning.

- After cleaning, the parts should be arranged in the order they were removed for efficient inspection, repair and reassembly.

- New brake discs and clutch discs must be soaked in ATF for at least 15 minutes before reassembly.

- All oil seal rings, clutch discs, clutch plates, rotating parts, and sliding surfaces should be coated with ATF prior to reassembly.

- All old gaskets and rubber O-rings must be replaced.

- Do not apply adhesive cement to gaskets or similar parts.

- Make sure that the ends of snap rings are not aligned with any cutouts. Make sure that snap rings are correctly installed into the grooves.

- If a worn bushing is to be replaced, the sub-assembly containing the bushing must also be replaced.

- Check the thrust bearings and races for wear or damage. Replace them if necessary.

- Use petroleum jelly to keep parts in place.

-

When working with seal packing (FIPG), observe the following:

- Using a razor blade and a gasket scraper, remove all of the old seal packing (FIPG) from the gasket surface.

- Thoroughly clean all components to remove any seal packing (FIPG).

- Clean both sealing surfaces with a non-residue solvent.

- Parts must be reassembled within 10 minutes of application. Otherwise, the seal packing (FIPG) must be removed and reapplied.

|

|

|

![2021 - 2022 MY Camry [10/2020 - 08/2022]; INTRODUCTION: REPAIR INSTRUCTION: INITIALIZATION](/t3Portal/stylegraphics/info.gif)