- Replacement of engine assembly

- Gas leak from exhaust system is repaired

| Last Modified: 11-20-2023 | 6.11:8.1.0 | Doc ID: RM100000001KVRP |

| Model Year Start: 2020 | Model: Camry | Prod Date Range: [09/2019 - 03/2020] |

| Title: FRONT SUSPENSION: FRONT SUSPENSION MEMBER: REMOVAL; 2020 MY Camry [09/2019 - 03/2020] | ||

REMOVAL

CAUTION / NOTICE / HINT

The necessary procedures (adjustment, calibration, initialization, or registration) that must be performed after parts are removed and installed, or replaced during front frame assembly removal/installation are shown below.

Necessary Procedures After Parts Removed/Installed/Replaced

|

Replaced Part or Performed Procedure |

Necessary Procedure |

Effect/Inoperative Function when Necessary Procedure not Performed |

Link |

|---|---|---|---|

|

*1: w/ Smart Key System

*2: w/o Smart Key System *3: When the ECM is replaced with a new one, reset memory is unnecessary. *: When performing learning using the Techstream. |

|||

|

Battery terminal is disconnected/reconnected |

Perform steering sensor zero point calibration |

Lane departure alert system (w/ Steering Control) |

|

|

Pre-collision system |

|||

|

Intelligent clearance sonar system* |

|||

|

Memorize steering angle neutral point |

Parking Assist Monitor System |

||

|

Panoramic view monitor system |

|||

|

Replacement of ECM |

Vehicle Identification Number (VIN) registration |

MIL comes on |

|

|

ECU communication ID registration (Immobiliser system) |

Engine start function |

||

|

|

Inspection After Repair |

|

|

|

Replacement of automatic transaxle assembly |

|

|

|

|

Replacement of ECM (If possible, read the transaxle compensation code from the previous ECM) |

|

||

|

Replacement of ECM (If impossible, read the transaxle compensation code from the previous ECM) |

|

||

for UA80E

|

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

|

for UB80E

|

ATF thermal degradation estimate reset |

The value of the Data List item "ATF Thermal Degradation Estimate" is not estimated correctly. |

|

|

Replacement of ECM*1 |

Code registration (Smart key System (for Start Function) |

|

|

|

Replacement of ECM*2 |

Code registration (Immobiliser system (w/o Smart Key System)) |

|

|

|

Front wheel alignment adjustment |

Perform system variant learning and acceleration sensor zero point calibration. |

|

|

|

Suspension, tires, etc. (The vehicle height changes because of suspension or tire replacement) |

Rear television camera assembly optical axis (Back camera position setting) |

Parking assist monitor system |

|

|

|

||

|

Panoramic view monitor system |

||

|

Rack and pinion power steering gear assembly |

|

|

|

PROCEDURE

1. REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

2. REMOVE FUEL DELIVERY GUARD (for A25A-FKS)

3. INSTALL ENGINE HANGER

4. REMOVE STEERING GEAR HEAT INSULATOR (for A25A-FKS)

5. DISCONNECT WIRE HARNESS

6. REMOVE FRONT FRAME ASSEMBLY

|

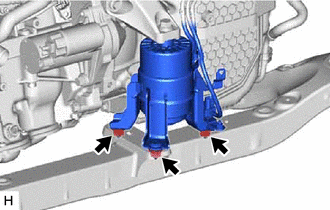

(a) Remove the 3 nuts and separate the front engine mounting insulator from the front frame assembly. |

|

|

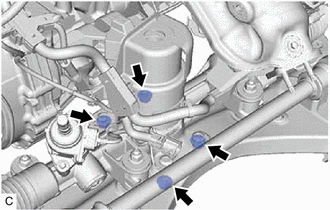

(b) Remove the 4 nuts and separate the rear engine mounting insulator from the front frame assembly. |

|

7. REMOVE FRONT STABILIZER BAR WITH BRACKET

8. REMOVE RACK AND PINION POWER STEERING GEAR ASSEMBLY

9. REMOVE FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY LH

|

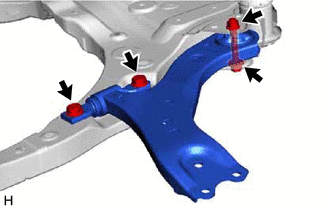

(a) Remove the 3 bolts, nut and front lower No. 1 suspension arm sub-assembly LH from the front frame assembly. NOTICE: Because the nut has its own stopper, do not turn the nut. Loosen the bolt with the nut secured. |

|

(b) Remove the front lower arm bushing stopper from the front lower No. 1 suspension arm sub-assembly.

10. REMOVE FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY RH

HINT:

Perform the same procedure as for the LH side.

11. REMOVE NO. 2 EXHAUST PIPE SUPPORT BRACKET

|

(a) Remove the 2 bolts and No. 2 exhaust pipe support bracket from the front frame assembly. |

|

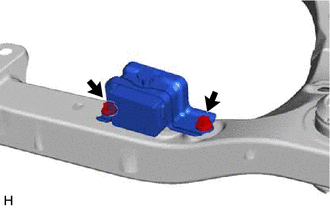

12. REMOVE FRONT SUSPENSION MEMBER DYNAMIC DAMPER

|

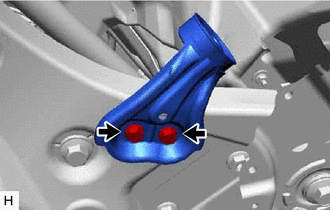

(a) Remove the 2 bolts and front suspension member dynamic damper from the front frame assembly. |

|

13. REMOVE FRONT SUSPENSION MEMBER BODY MOUNTING FRONT STOPPER

(a) Remove the 2 front suspension member body mounting front stoppers from the front frame assembly.

14. REMOVE FRONT SUSPENSION MEMBER BODY MOUNTING REAR STOPPER

(a) Remove the 2 front suspension member body mounting rear stoppers from the front frame assembly.

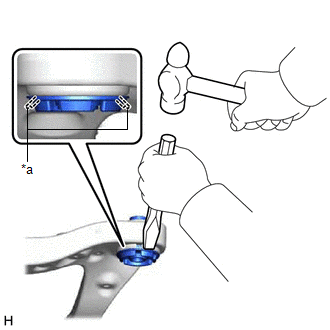

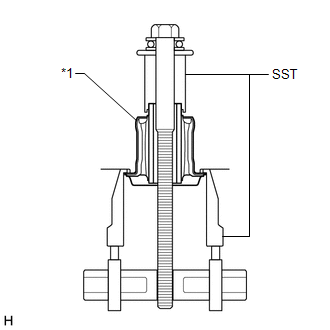

15. REMOVE FRONT SUSPENSION MEMBER BODY MOUNTING FRONT CUSHION (for LH Side)

|

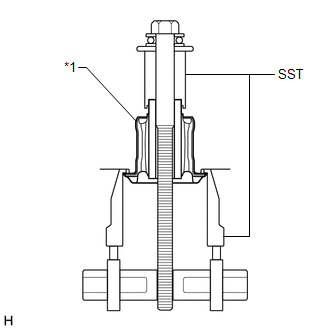

(a) Using a chisel and hammer, kink the flange of the front suspension member body mounting front cushion as shown in the illustration. |

|

(b) Apply lubricant to the contact surfaces of the front suspension member body mounting front cushion.

|

(c) Install SST as shown in the illustration. SST: 09830-10010 09830-01010 09830-01040 09830-01050 SST: 09950-40011 09951-04020 09952-04010 09954-04010 09955-04011 09958-04011 NOTICE: Apply molybdenum grease to the threads and tip of the SST center bolt before use. |

|

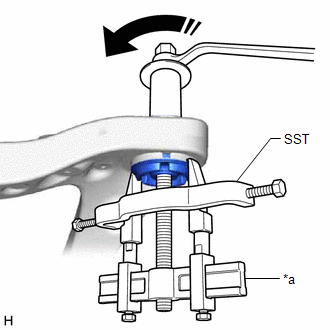

(d) Turn the SST center bolt as shown in the illustration to create a clearance between the front suspension member body mounting front cushion and the front frame assembly.

|

*a |

Hold |

|

Turn |

(e) While applying lubricant to the front suspension member body mounting front cushion through the clearance, gradually remove the front suspension member body mounting front cushion.

NOTICE:

- Tighten SST slowly and evenly.

- Be careful as the mounting cushion may fly out.

- The mounting cushion cannot be reused.

16. REMOVE FRONT SUSPENSION MEMBER BODY MOUNTING FRONT CUSHION (for RH Side)

HINT:

Perform the same procedure as for the LH side.

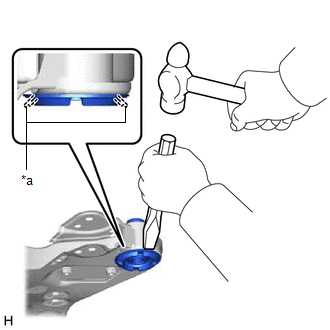

17. REMOVE FRONT SUSPENSION MEMBER BODY MOUNTING REAR CUSHION LH

|

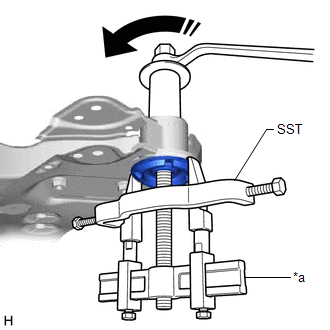

(a) Using a chisel and hammer, kink the flange of the front suspension member body mounting rear cushion LH as shown in the illustration. |

|

(b) Apply lubricant to the contact surfaces of the front suspension member body mounting rear cushion LH.

|

(c) Install SST as shown in the illustration. SST: 09830-10010 09830-01010 09830-01040 09830-01050 SST: 09950-40011 09951-04020 09952-04010 09954-04010 09955-04011 09958-04011 NOTICE: Apply molybdenum grease to the threads and tip of the SST center bolt before use. |

|

(d) Turn the SST center bolt as shown in the illustration to create a clearance between the front suspension member body mounting rear cushion LH and the front frame assembly.

|

*a |

Hold |

|

Turn |

(e) While applying lubricant to the front suspension member body mounting rear cushion LH through the clearance, gradually remove the front suspension member body mounting rear cushion LH.

NOTICE:

- Tighten SST slowly and evenly.

- Be careful as the mounting cushion may fly out.

- The mounting cushion cannot be reused.

18. REMOVE FRONT SUSPENSION MEMBER BODY MOUNTING REAR CUSHION

HINT:

Perform the same procedure as for the front suspension member body mounting rear cushion LH.

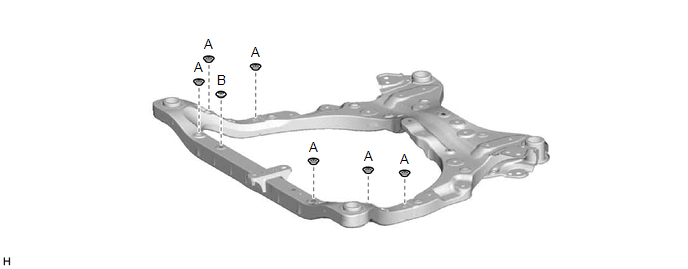

19. REMOVE HOLE PLUG

(a) Remove the 7 hole plugs from the front frame assembly.

HINT:

There are 2 different shapes of hole plug.

|

|

|

![2018 - 2020 MY Camry [06/2017 - 10/2020]; PARK ASSIST / MONITORING: INTELLIGENT CLEARANCE SONAR SYSTEM: CALIBRATION](/t3Portal/stylegraphics/info.gif)